Power DevicesOsai2021-02-10T17:07:51+00:00

Flexible and Scalable

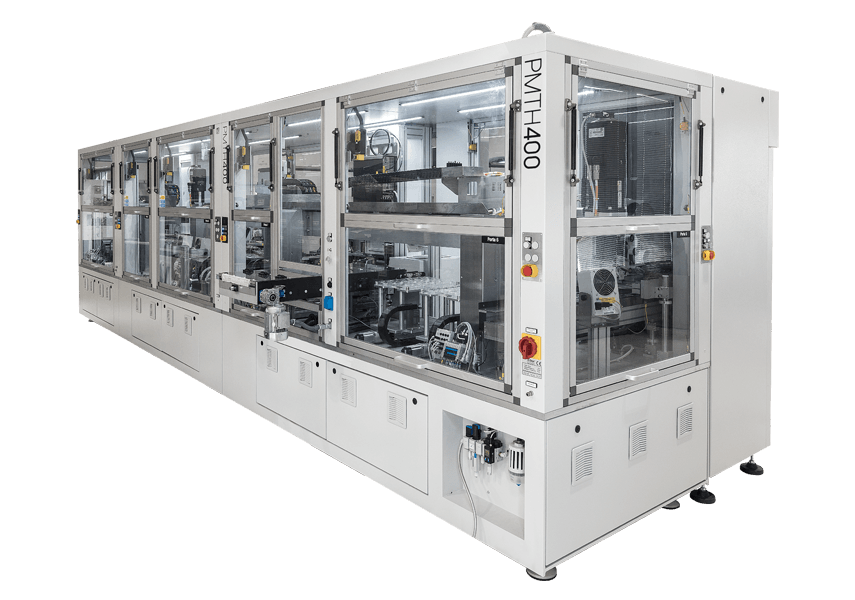

The Osai PMTH ( Power module test handler ) is a top class equipment conceived to test Power Modules. A very high productivity, combined with an extreme reliability, makes the PMTH the perfect standard solution for the mass production.

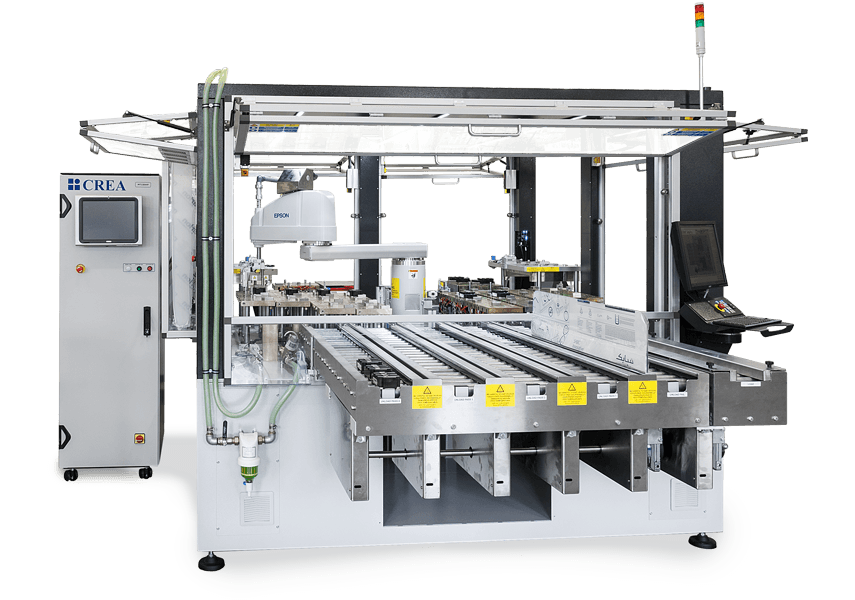

The NeoHandler for discrete components is the best solution for the test of IGBTs, Mosfet and other power devices. The most common packages are used and compatible with the NeoHandler, like TO247, TO220, D2Pack. The perfect integration with specific hi-power ATE makes the NeoHandler the perfect solution to reduce the strain inductance and make the most of the ATE performances.

POWER MODULES

Flexible and Scalable

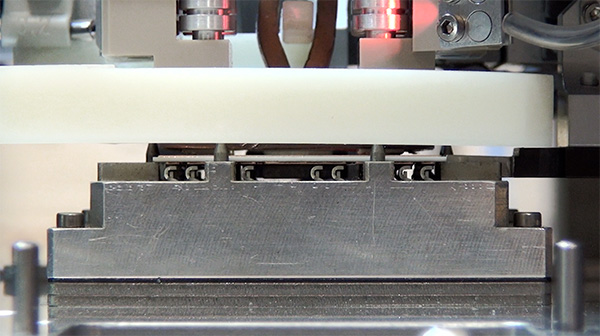

Test Handler for power module

The Osai PMTH ( Power module test handler ) is a top class equipment conceived to test Power Modules. A very high productivity, combined with an extreme reliability, makes the PMTH the perfect standard solution for the mass production.

The Osai PMTH is configurable for different packages, PIM, Econopack, HPD and many others. The conversion time is very low, and the standard approach makes it configurable and upgradable on field to many different test features.

PLAY VIDEO

DOWNLOAD DATA SHEET

0

Units per hour

0s

Testing time

PMTH’s Keypoints

MAIN FEATURES

PMTH

MAIN CHARACTERISTICS

The OSAI Power module test cell series, provides a breakthrough scalable and configurable solution for Power Module test:

- Hot temperature test

- Ambient temperature test

- AC/DC Test capability

- ISO Test capability

- Tray and Blister input/output media

- Reject bin feed on tubes or tape

- Configurable sorting

- Leads check

- Laser marking

- Optical inspection

- Weight check

- Flip station

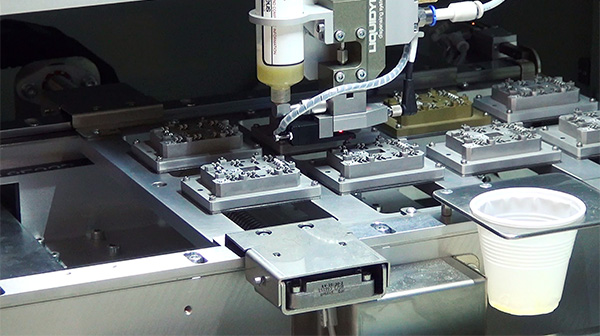

NEOHANDLER

Mass Production Testing

The NeoHandler for discrete components is the best solution for the test of IGBTs, Mosfet and other power devices. The most common packages are used and compatible with the NeoHandler, like TO247, TO220, D2Pack. The perfect integration with specific hi-power ATE makes the NeoHandler the perfect solution to reduce the strain inductance and make the most of the ATE performances.

Keypoints

NEOHANDLER

MAIN CHARACTERISTICS

- Pass devices output Tube (N° 20 tubes autonomy)

- N° 5 programmable bins for NOK devices in box

- Loading Fresh devices feeded in Tube (N° 20 tubes autonomy)

- Multi Pick-Up developed with scalable multisite according to the test time

- Tester and socketboard integration

POWER DEVICES PACKAGING

Easy Mass Production

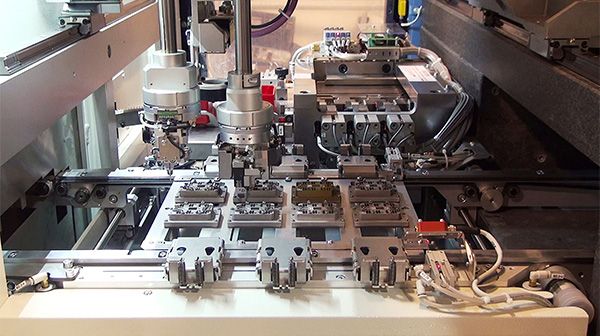

Being an automation company, Osai can offer many solutions for the automatic assembly of power modules. From the bare mastercard to the final test, the Osai experience in semiconductor application automation can make the mass production easy, reliable and 100% human error free.

Keypoints

POWER DEVICES PACKAGING

MAIN CHARACTERISTICS

- Laser scribing for ceramic substrate

- Laser marking for ceramic substrate

- Breaking machines for ceramic substrate

- Induction pin soldering ( patented ) or automatic pin insertion

- Plastic case assembly, gluing, screwing and UV curing

- Sil gel vacuum potting