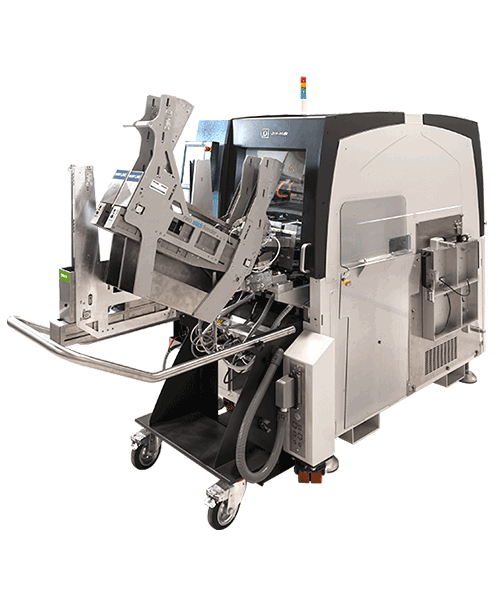

NEOHANDLER

Mass Production

Test Handler for MEMS

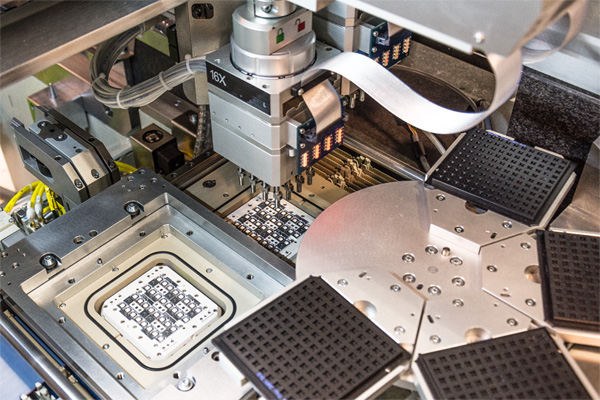

OSAI neohandler is the top-notch solution for Semiconductor Companies, for testing MEMS and Power devices in mass production (up to 25KUPH). Neohandler small footprint 900 x 1.600mm saves production area, increasing drastically the throughput (UPH / m2), by using scalable concept.

High flexibility allows the customer to change setup in 15 minutes, maximizing the investment: Input / output trolley can be replaced with different magazine type and Multipick up tool can be easily and simply scaled according to the need.

The wide range of Multisocket and multipick up tools developed by OSAI, allows the customers to manage different packages. Neohandler can be properly configured with different Stimulus Chambers, according to specific MEMS to be conditioned.

PLAY VIDEO

DOWNLOAD DATA SHEET

0

UPH

0s

Testing time

Handler’s Keypoints

Acceptable devices packages

The Handler is conceived as a general purpose equipment.

However the full compatibility for a certain package is given from the contactors.

The Handler is compatible with the following packages:

HANDLING

REAR SIDE TRAYS INPUT OUTPUT TROLLEY:

The Handler is equipped with an input/output trolley.

Trolley is conceived to be changed on field to reduce the setup time in case of a Handler re-configuration.

A fast changing system with a mechanical self alignment system guarantees the input output repeatability.

Trolley can be configured with different kinds of input output feeding.

Input:

- Jedec Tray Feeder

- Tube

- Bowl

- Film frame

Output:

- Jedec Tray

- Tube

- T&R

- Bowl

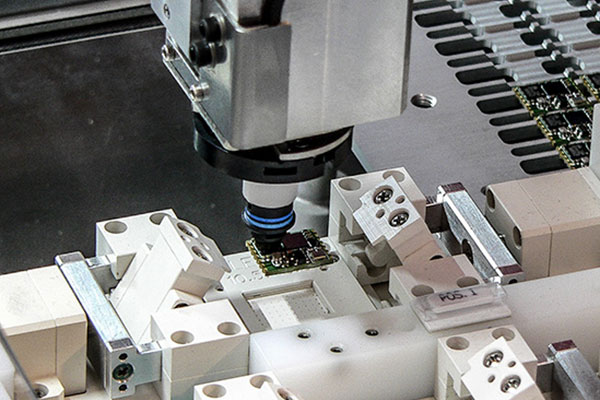

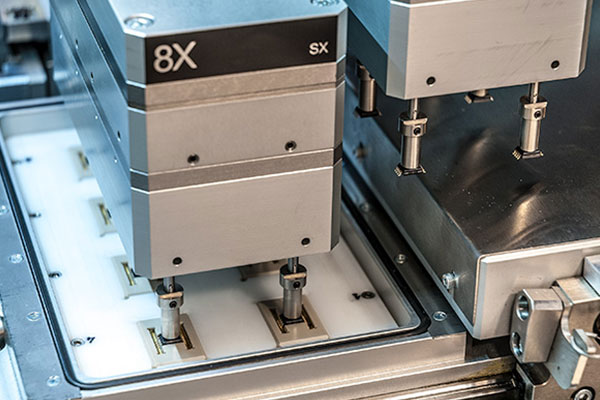

TOOLS

EACH HEAD IS EQUIPPED WITH A SPECIFIC PICK-UP TOOL

Main characteristics of the Pick-Up tools are:

- Fast changing (less than 1 minute) and standard Osai interface (includes all the electrical and pneumatic connections)

- 1, 4, 8, 16, 35 sites, other multisite available on the roadmap

- Independent 10mm Z stroke each single picker

- Independent vacuum command and control on each single picker

- Fine adjustable detaching air blow

- Single site collision sensor

- On picker precisor for device pre-alignment

- Internal code for setup-recipe verification

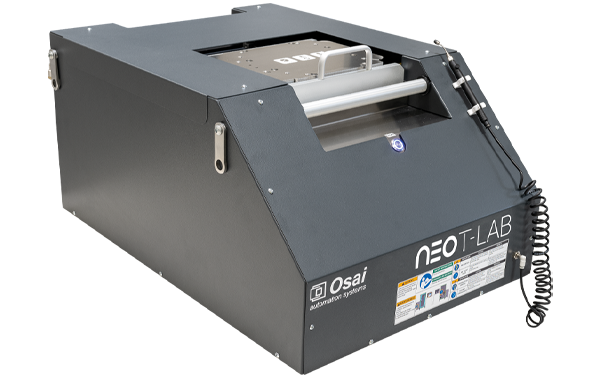

NEOT-LAB

Lab Equipment for environmental MEMS

Neo T-LAB is OSAI’s ultimate desk size lab test solution. With its compact size Neo T-LAB is the smallest conditioning chambers in the world allowing the R&D fine tuning directly in laboratory.

In addition to the smallest footprint, the Neo T-LAB advanced offers the possibility to be configured with several test stimuli, such as temperature, pressure, humidity and gas.

Neo T-LAB is also a tailor made solution: the possibility to design the test chamber based on customer needs, allows the transition from laboratory to mass production in just few steps.

PLAY VIDEO

DOWNLOAD DATA SHEET

0°C

Temperature accuracy

0°C

Temperature stability

0s

Average temperature settling time

EPC’s Keypoints

STIMULI

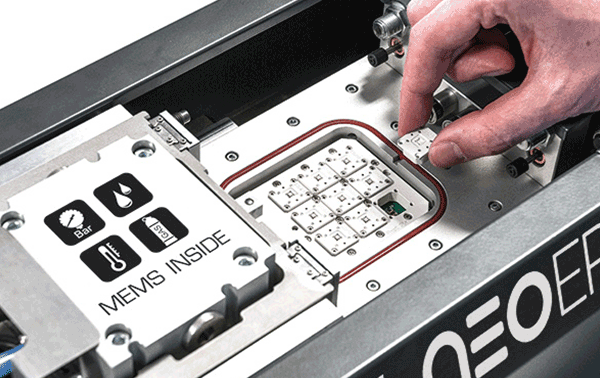

ENGINEERING PRESSURE CHAMBER

MAIN CHARACTERISTICS

- Temperature range: -20° up to 80°C or -40° up to 125°C

- Temperature accurancy: 0,5°C

- Temperature stability: 0,3°C

- Average setting time: 10s

- Pressure range: 0 up to 6bar

- Pressure setting time: 3s

- Pressure stability: according to external regulator

- MEMS communication protocol: SPI, I2C, GPIO

- PC Interface: USB

STIMULI

HIGH ACCURATE STIMULI

- Thermal stimuli unit

- Pressure stimuli unit

- Gas stimuli unit

- Humidity stimuli unit