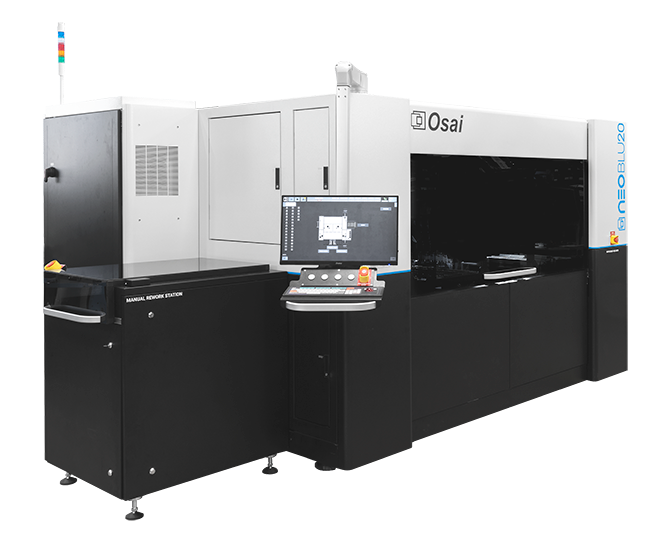

NEO BLU

Burn in loader/unloader 20.000 UPH

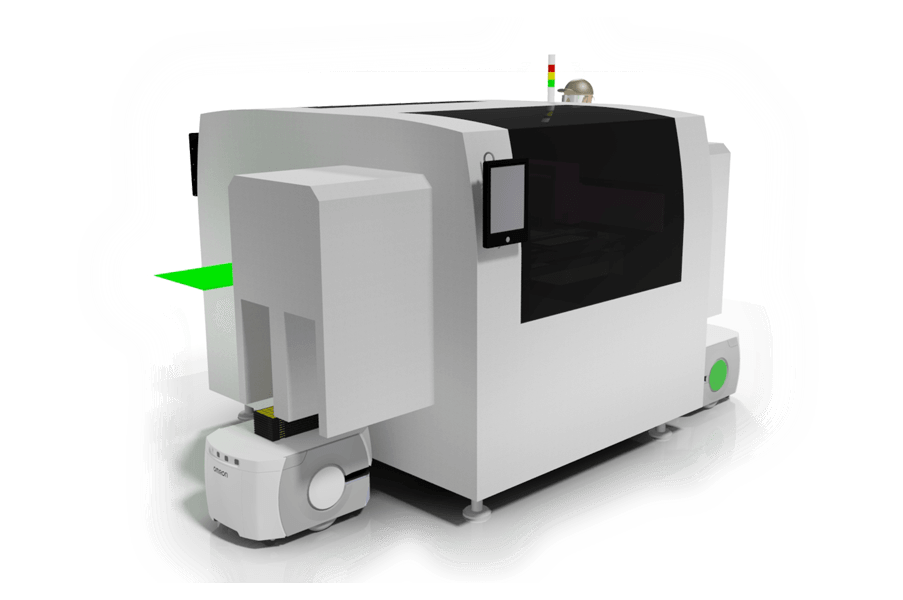

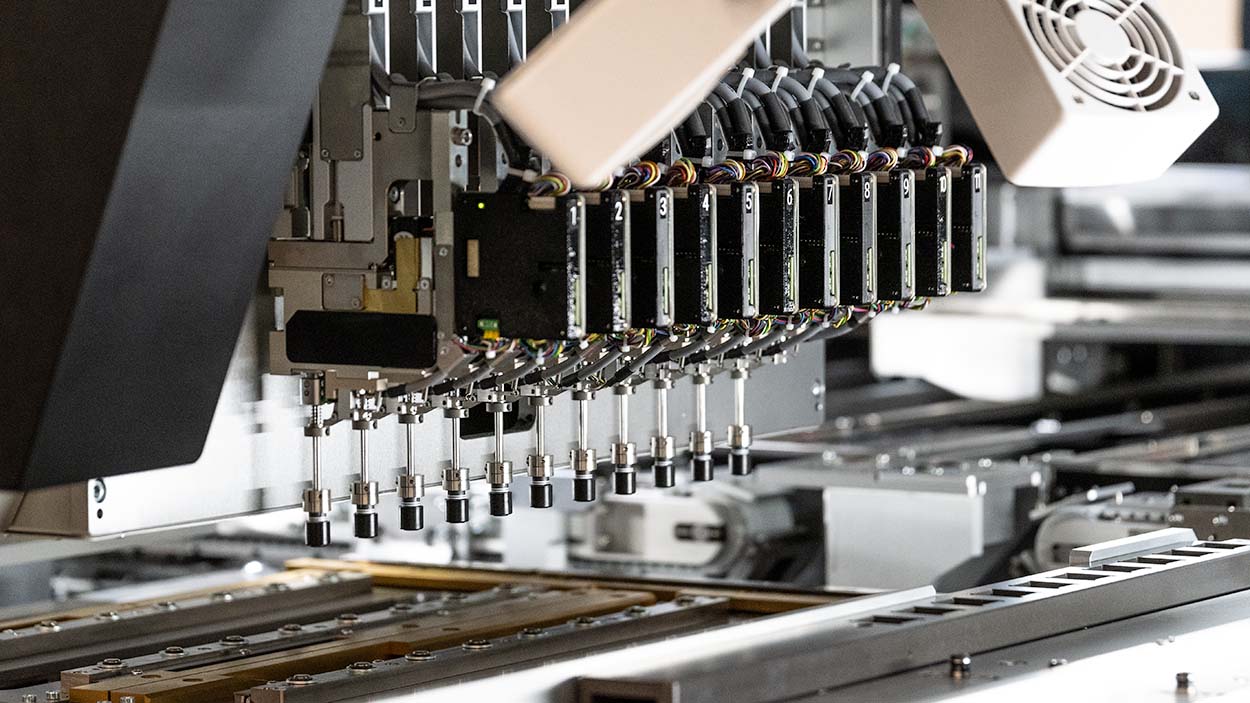

Innovative burn-in loader unloader for extreme mass production. Osai NeoBLU is a disrupting Burn-in Loader/Unloader/Sorter. The focus on this innovative equipment is based on 3 main pillars:

Extremely high productivity

- – High dynamics and accurate linear motors, with granite base and a super-stiff base frame

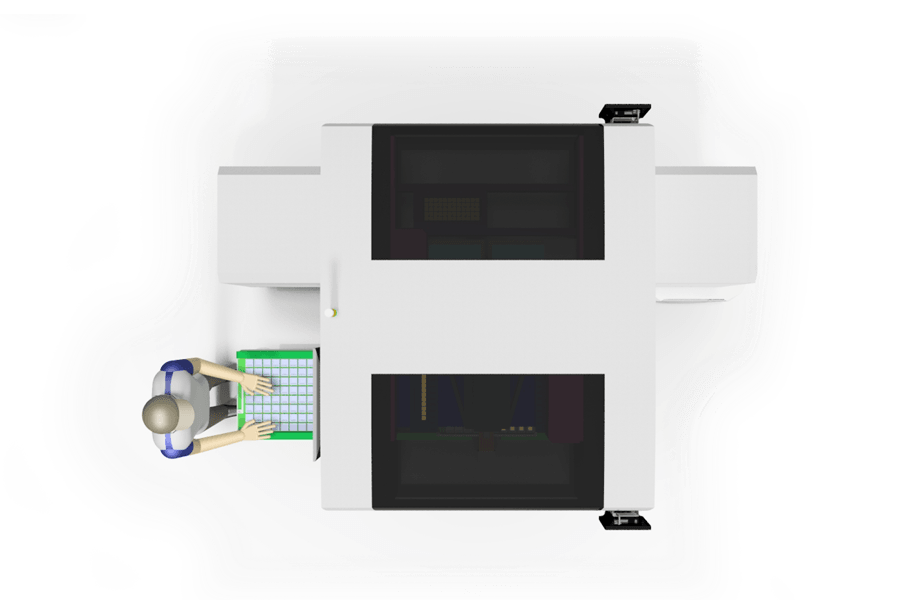

- – 2x socket opener

- – 2x BIB multipicker heads, with pitch converters

- – BIB index time close to zero

- – 3x set of precisors always available in the machine ( zero setup time )

- – 4x Jedec trays feeder

- – 2x Jedec pick up multipicker heads with pitch converter

- – 1x specific P&P robot to manage the rejects only

- – Auto alignment features to reduce the setup time and the self-diagnostic

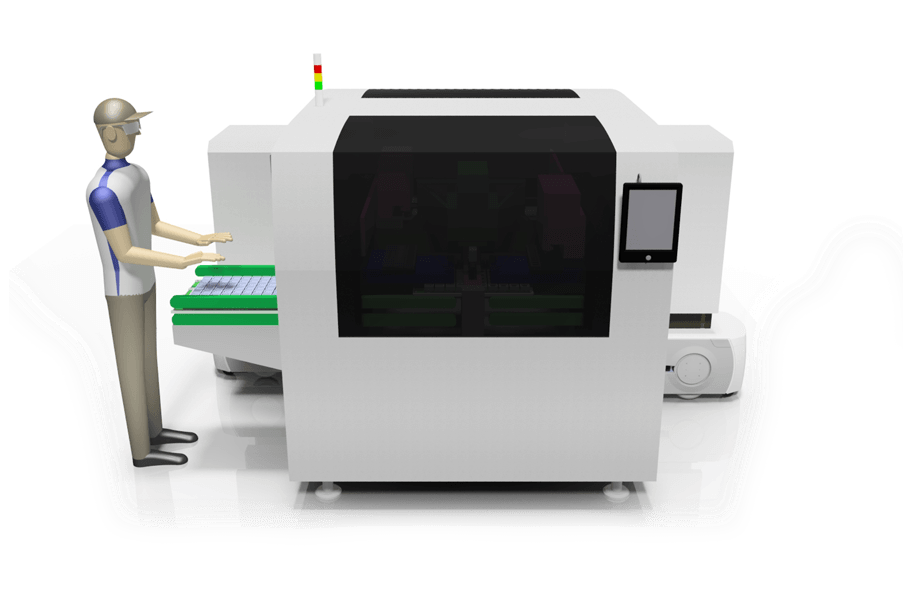

- – Graphic HMI to guide the operator in every operation

- – Off-Line Manual station for recovery actions

Native Full Automation

- – Interface with MES, native SECS-Gem interfaced SW

- – Loading and unloading by robots ( AGV )

- – Possibility to load/unload boards from trolleys

- – Possibility to integrate the NeoBLU into an automatic cell, full process Oven > BLU > Oven

- – NeoBLU can work in exchange mode, with 100% mixing proof cycle

- – Multi-lot operation mode

- – Lights-off Factory READY

Full Traceability Management (with the use of advanced vision systems for reading 2d codes)

Every BIB is scanned when getting in and getting out the machine. The NeoBLU collect and check the following data:

- – Board ID

- – Sockets ID

- – DUT ID

Every JEDEC Tray is scanned when getting in and getting out the machine. The NeoBLU collect and check the following data:

- – Tray ID

- – DUT ID

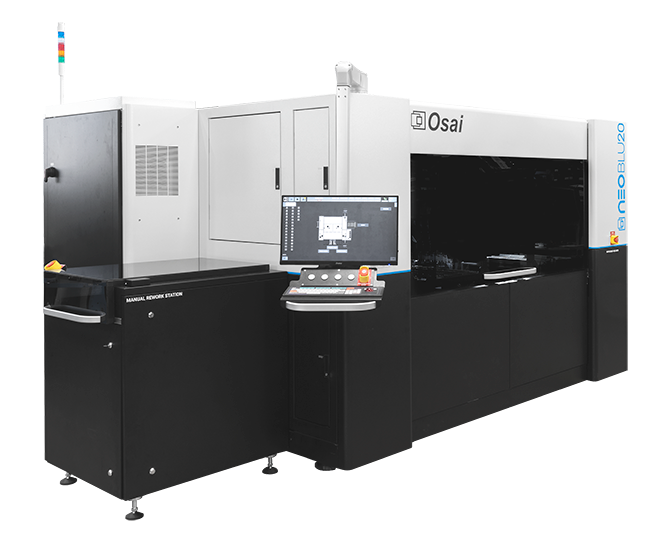

BURN IN LOADER/UNLOADER

MAIN CHARACTERISTICS

- No Stop Loading/Unloading

- No Stop Jam Recovery (manual recovery station)

- Auto diagnostic Features

- Socket Cleaning Station

- Auto Teaching

- Auto Correction Features

- Few and Simple change kits

- ESD class 0

- Low Footprint

- Full Automation Ready (AGV)

AUTO TROLLEY PRE-TEST STATION

ATPS

Auto Trolley Pre-Test Station

ATPS is the Osai In Line Concept solution and consists of three modules connected together:

– BLU Loader/Unloader, that moves the BIB from BLU to Pretester and vice versa

– Pretest + buffer, that performs visual inspection, pretest, and DUT/Socket replacement

– Trolley Loader/Unloader,that moves the BIB from Pretester to Trolley and vice versa It is equipped with two BIB transport levels:one in the upper area of the system (Working Area) and one in the lower;

In details BLU Loader/Unloader has the function to manage BIBs transition to/for BLU; Pretester is based on the OsaiNeo Handler Modula standard system and Trolley Loader Unloader is the handling module that moves BIBs from Pretester to Trolley and vice versa and it also works as a dynamic Docking Station for Trolleys.

In details BLU Loader/Unloader has the function to manage BIBs transition to/for BLU; Pretester is based on the OsaiNeo Handler Modula standard system and Trolley Loader Unloader is the handling module that moves BIBs from Pretester to Trolley and vice versa and it also works as a dynamic Docking Station for Trolleys.