E-Mobility.

E-Mobility.

Electrifying the road ahead: solutions for E-Mobility.

Osai believes in making e-mobility not just a choice but a seamless and empowering experience for users. In an era marked by profound shifts, the automotive industry is undergoing a transformative journey.

The e-mobility manufacturing sector encompasses the production of electric vehicles (EVs), including cars, buses, trucks, motorcycles, and bicycles, as well as the associated infrastructure and components such as batteries, charging stations, and electric drivetrains.

Nowadays we talk of electric mobility as the strongest expression of modern technology, but perhaps not everyone knows that the first electric car dates back more than a century.

In the 1830s and 1840s, inventors in Europe and the United States began experimenting with electric propulsion systems. One of the earliest electric vehicles was built by Thomas Davenport, in 1834: the first working electric motor and electric vehicle, a small locomotive that used two electromagnets, a pivot and a battery, and in 1859 Gaston Planté invented the first rechargeable battery. For the first real electric car, however, we must wait until the invention of British inventor Thomas Parker in 1884.

Shorter range, better roads, battery problems and more reliable improved petrol have led to a halt in the popularity of the electric car, and it was only in the 1990s that manufacturers began to look at electrics as a real road to the future for mobility, and one that is really being pursued today.

One of the key is challenges facing electric vehicles was the limited energy storage capacity of batteries, which constrained their range and performance.

However, advancements in battery technology, particularly the development of lithium-ion batteries with higher energy density and improved durability, transformed the viability of electric vehicles.

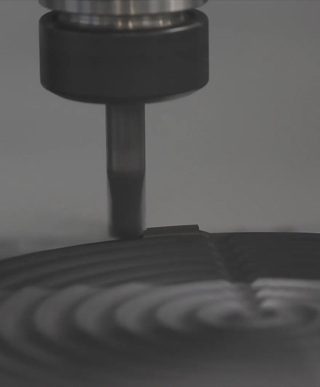

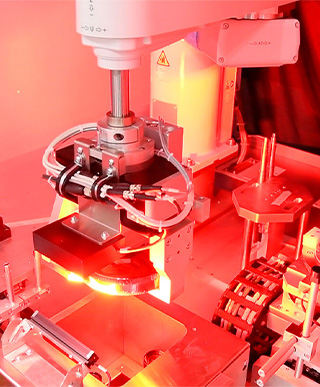

Battery manufacturing involves the production of lithium-ion batteries, which store and provide energy to power the electric motors. This sector includes battery cell production, battery pack assembly, and battery management system development.

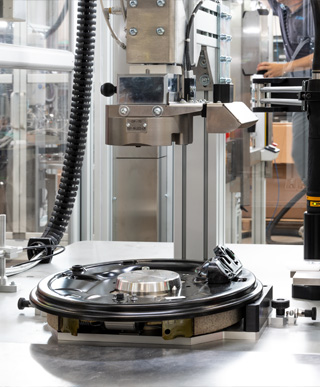

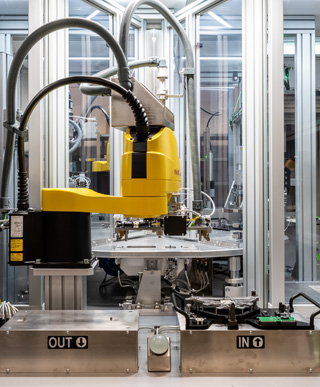

The e-mobility ecosystem relies also electric drivetrain manufacturing that involves the production of components such as electric motors, power electronics, inverters, and transmission systems that convert electrical energy into mechanical power to drive the wheels of electric vehicles.

E-mobility has expanded beyond passenger cars to include electric buses, trucks, motorcycles, bicycles, and even electric aviation.

Advances in battery technology, electric drivetrains, and charging infrastructure have made electric mobility feasible across a wide range of transportation modes.

This industry continues to evolve rapidly, with ongoing advancements: electric vehicles can play a significant role in the transition to sustainable transportation and the reduction of greenhouse gas emissions in the coming years. Osai works daily to be at the forefront of this revolution, offering innovative solutions that drive change and shape the future of mobility.

Electrifying the road ahead: solutions for E-Mobility.

Osai believes in making e-mobility not just a choice but a seamless and empowering experience for users. In an era marked by profound shifts, the automotive industry is undergoing a transformative journey.

The e-mobility manufacturing sector encompasses the production of electric vehicles (EVs), including cars, buses, trucks, motorcycles, and bicycles, as well as the associated infrastructure and components such as batteries, charging stations, and electric drivetrains.

Nowadays we talk of electric mobility as the strongest expression of modern technology, but perhaps not everyone knows that the first electric car dates back more than a century.

In the 1830s and 1840s, inventors in Europe and the United States began experimenting with electric propulsion systems. One of the earliest electric vehicles was built by Thomas Davenport, in 1834: the first working electric motor and electric vehicle, a small locomotive that used two electromagnets, a pivot and a battery, and in 1859 Gaston Planté invented the first rechargeable battery. For the first real electric car, however, we must wait until the invention of British inventor Thomas Parker in 1884.

Shorter range, better roads, battery problems and more reliable improved petrol have led to a halt in the popularity of the electric car, and it was only in the 1990s that manufacturers began to look at electrics as a real road to the future for mobility, and one that is really being pursued today.

One of the key is challenges facing electric vehicles was the limited energy storage capacity of batteries, which constrained their range and performance.

However, advancements in battery technology, particularly the development of lithium-ion batteries with higher energy density and improved durability, transformed the viability of electric vehicles.

Battery manufacturing involves the production of lithium-ion batteries, which store and provide energy to power the electric motors. This sector includes battery cell production, battery pack assembly, and battery management system development.

The e-mobility ecosystem relies also electric drivetrain manufacturing that involves the production of components such as electric motors, power electronics, inverters, and transmission systems that convert electrical energy into mechanical power to drive the wheels of electric vehicles.

E-mobility has expanded beyond passenger cars to include electric buses, trucks, motorcycles, bicycles, and even electric aviation.

Advances in battery technology, electric drivetrains, and charging infrastructure have made electric mobility feasible across a wide range of transportation modes.

This industry continues to evolve rapidly, with ongoing advancements: electric vehicles can play a significant role in the transition to sustainable transportation and the reduction of greenhouse gas emissions in the coming years. Osai works daily to be at the forefront of this revolution, offering innovative solutions that drive change and shape the future of mobility.