Automatic Silicon Carbide (SiC) Seed Preparation System

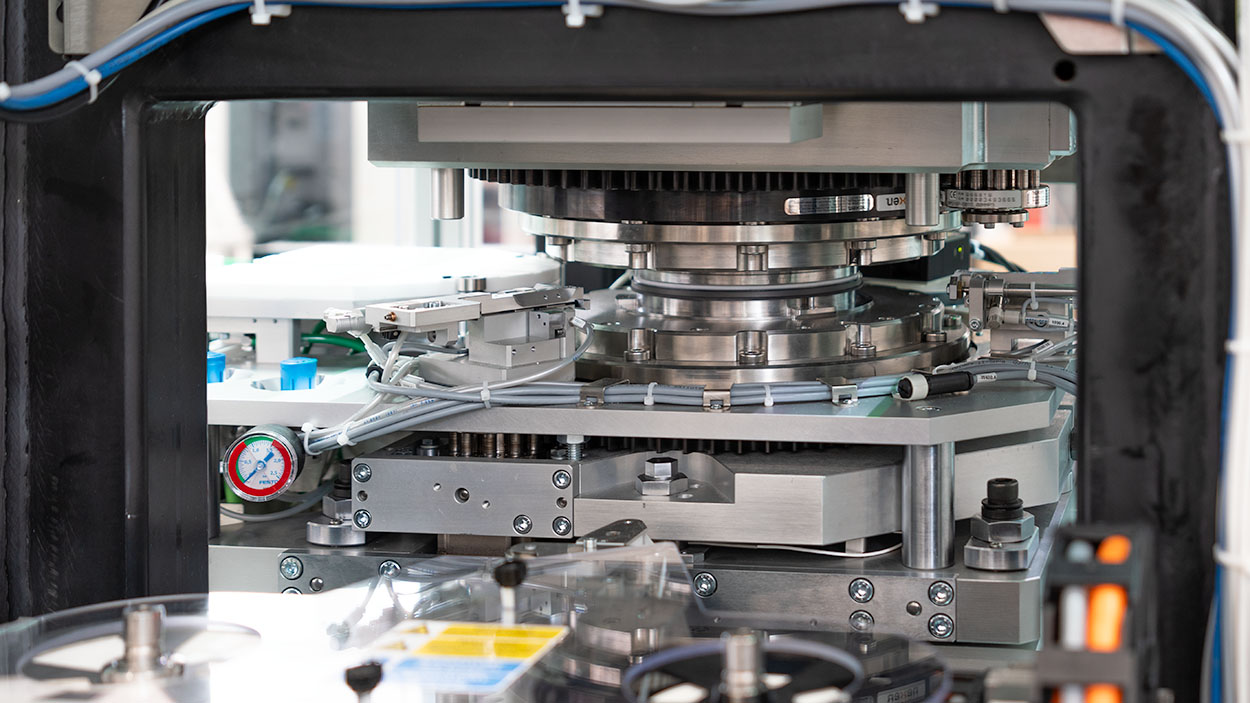

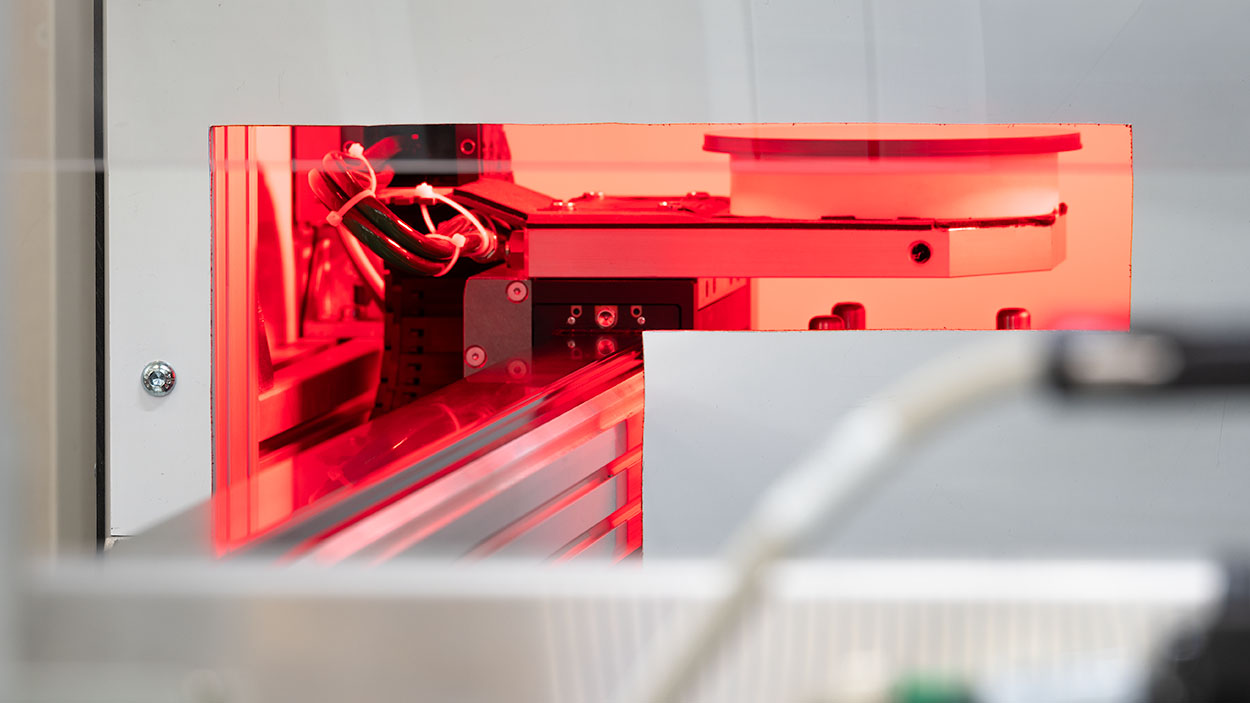

Auto Seed Attach is the new Osai solution for the subsequent crystal growth processes, bonding Seed and Lid with extreme precision and cleanliness, ensuring stability and repeatability of the process.

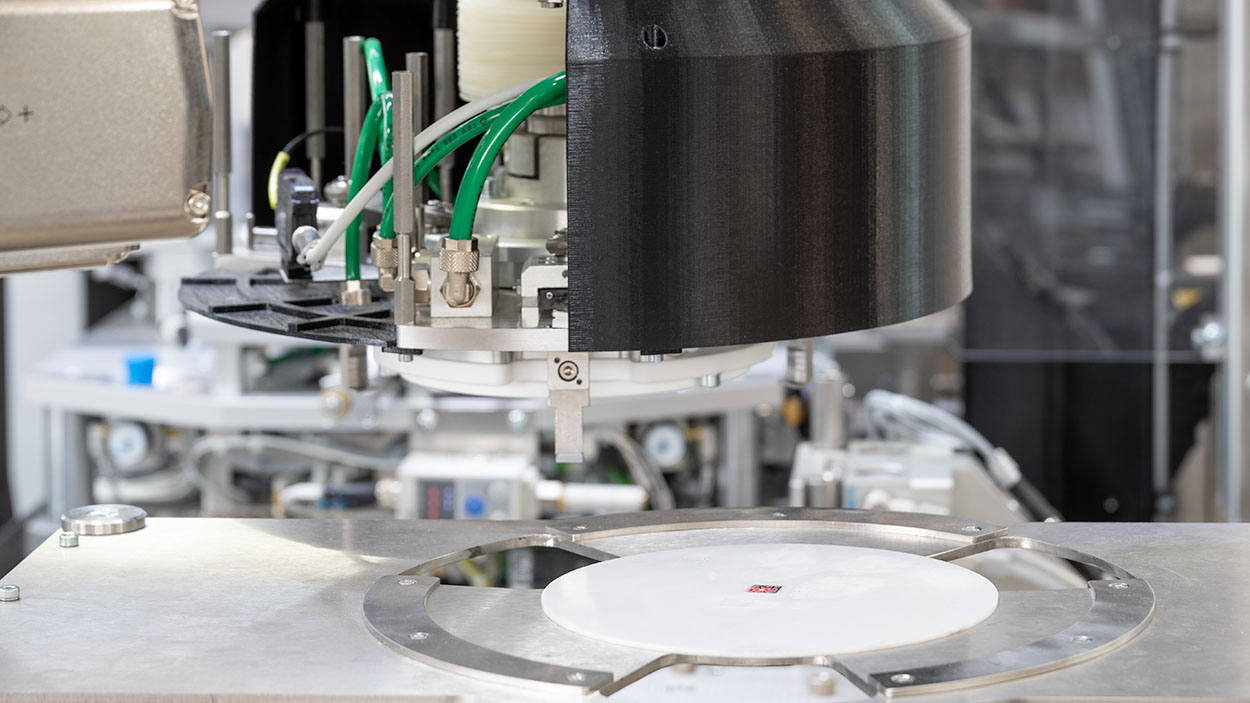

Optimized seed preparation is crucial for initiating high-quality SiC crystal growth processes. The Osai solution has an AOI vision system that allows to visualize the quality of the attachment of seeds by mapping the air bubbles created during the process by carbon monoxide.

The system is designed for 6-inches crystals but can be processed up to 12-inches ready.

Automatic Silicon Carbide (SiC) Seed Preparation System

Auto Seed Attach is the new Osai solution for the subsequent crystal growth processes, bonding Seed and Lid with extreme precision and cleanliness, ensuring stability and repeatability of the process.

Optimized seed preparation is crucial for initiating high-quality SiC crystal growth processes. The Osai solution has an AOI vision system that allows to visualize the quality of the attachment of seeds by mapping the air bubbles created during the process by carbon monoxide.

The system is designed for 6-inches crystals but can be processed up to 12-inches ready.