Scalable and Modular Line for High Speed Production

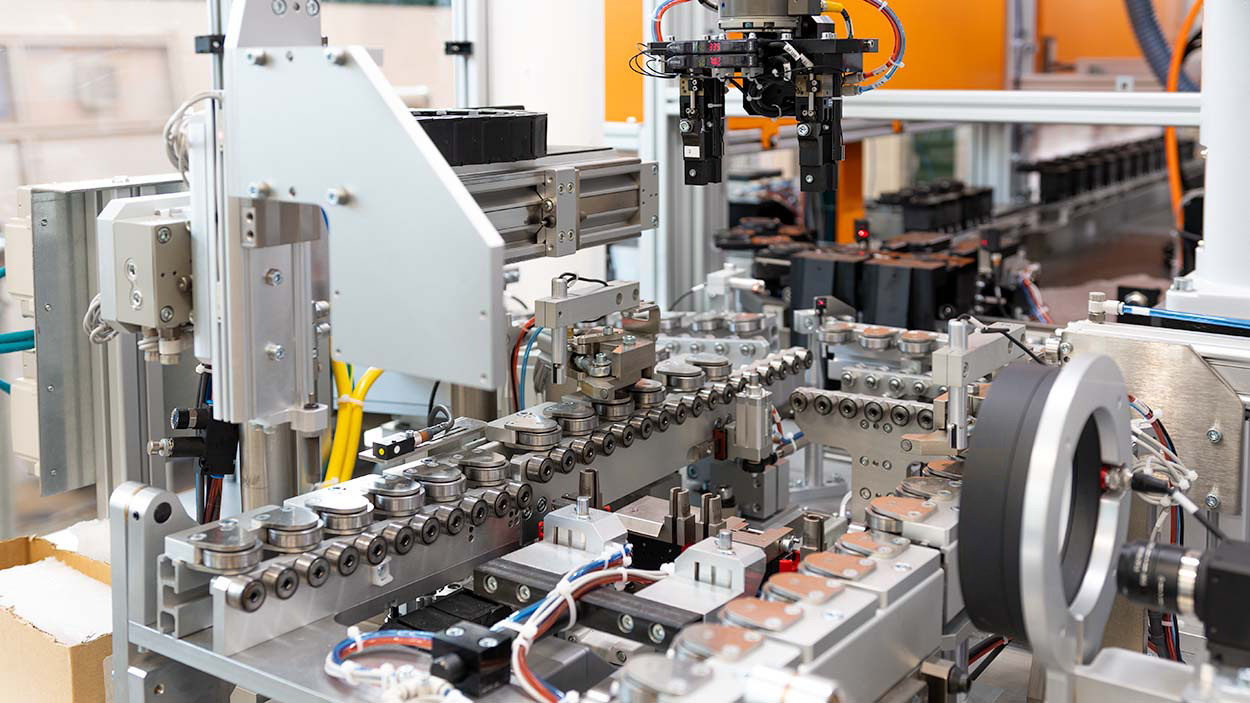

Fully automatic modular assembling and test line where each module is a stand-alone machine with independent PLC and PC equipped with different stations and technologies. The modules are connected one by one with Ethernet connection. The products are moved by high-speed magnetic conveyor system.

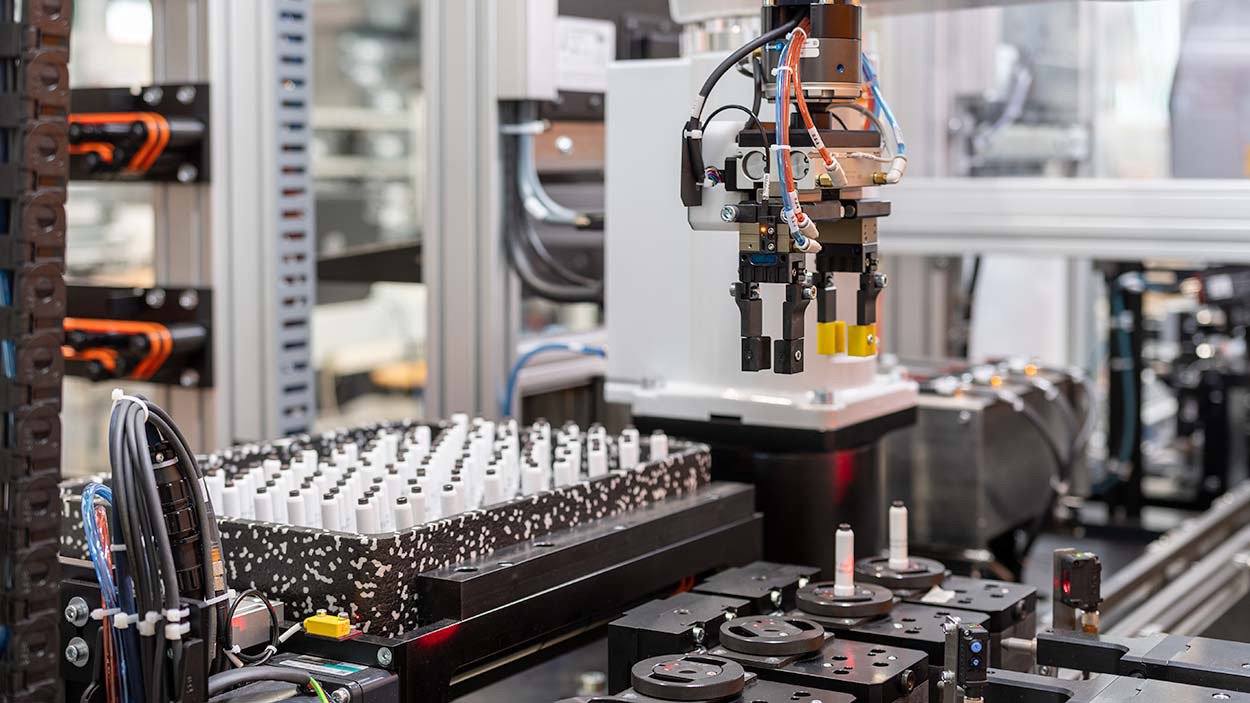

The OSAI solution handles the entire assembly process of spark plugs. The production line begins with the automatic feeding of the ceramic bodies of the spark plugs. This ensures a continuous supply of components correctly positioned for the assembly process without any operator intervention.

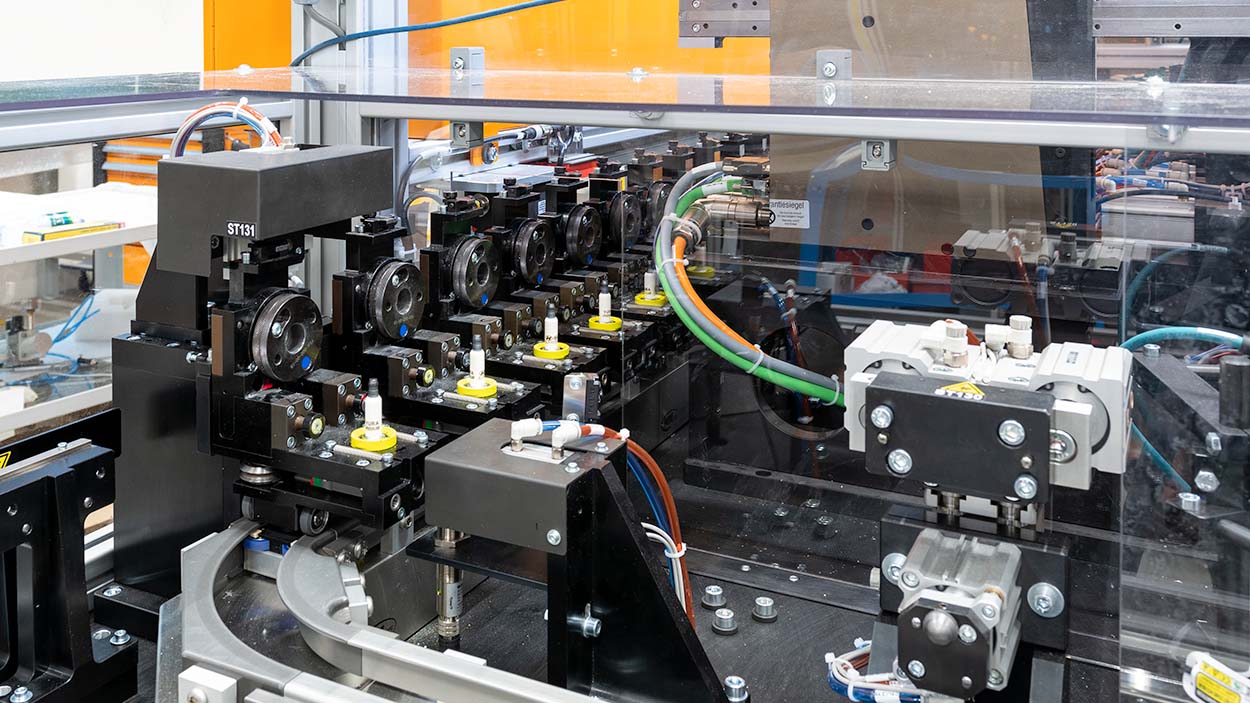

Once the ceramic body is in place, it is assembled with the metal housing, the outer metal part of the spark plug. This process includes the insertion, alignment, and securing of the two parts, ensuring a solid and precise connection.

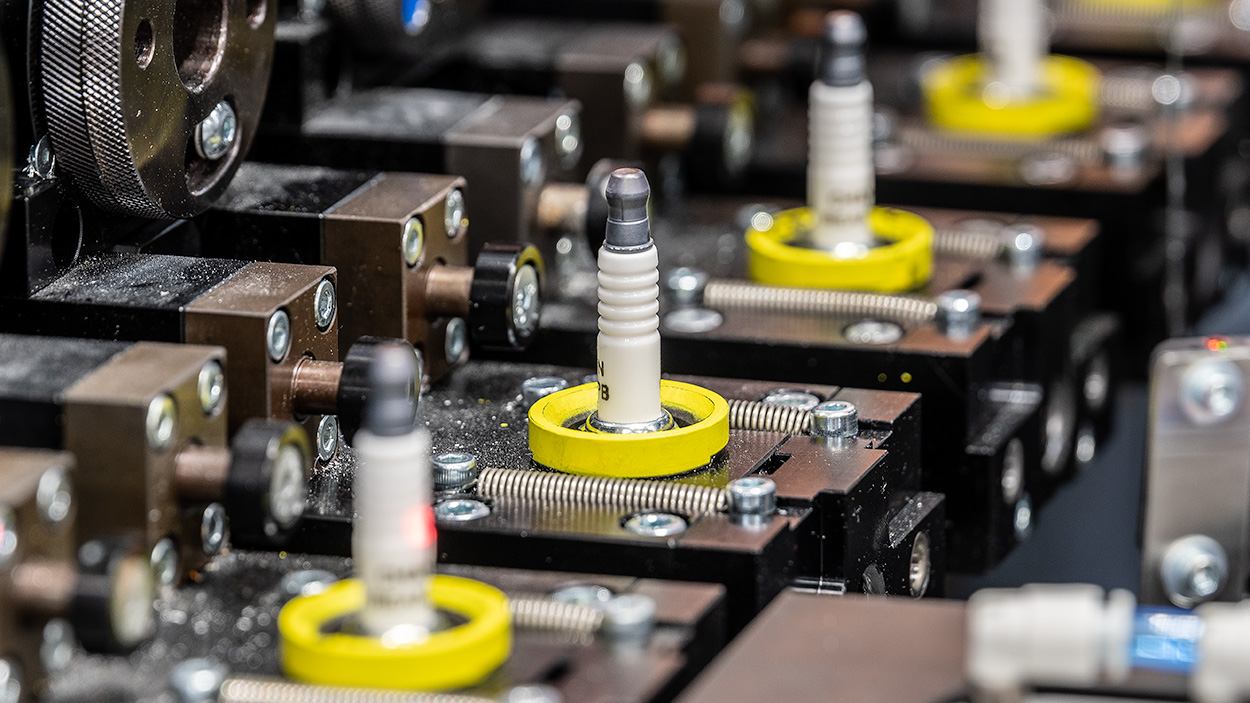

The line handles the precise bending of the electrode. Accurate bending of the electrode is crucial to ensure the proper functioning of the spark plug, facilitating the spark required for engine ignition.

The bending is done by axis electric driven, in continuous feedback with the camera in backlight control.

The module can be adapted according to the product: new module and new station could be integrated plug and play at a later time.

Scalable and Modular Line for High Speed Production

Fully automatic modular assembling and test line where each module is a stand-alone machine with independent PLC and PC equipped with different stations and technologies. The modules are connected one by one with Ethernet connection. The products are moved by high-speed magnetic conveyor system.

The OSAI solution handles the entire assembly process of spark plugs. The production line begins with the automatic feeding of the ceramic bodies of the spark plugs. This ensures a continuous supply of components correctly positioned for the assembly process without any operator intervention.

Once the ceramic body is in place, it is assembled with the metal housing, the outer metal part of the spark plug. This process includes the insertion, alignment, and securing of the two parts, ensuring a solid and precise connection.

The line handles the precise bending of the electrode. Accurate bending of the electrode is crucial to ensure the proper functioning of the spark plug, facilitating the spark required for engine ignition.

The bending is done by axis electric driven, in continuous feedback with the camera in backlight control.

The module can be adapted according to the product: new module and new station could be integrated plug and play at a later time.