Scalable and Modular Line for Automotive Components

Osai flexible module systems are designed to adapt to a wide range of requirements. Whether you need a simple manual setup or a complex automated line, Osai systems can be customized to fit your needs.

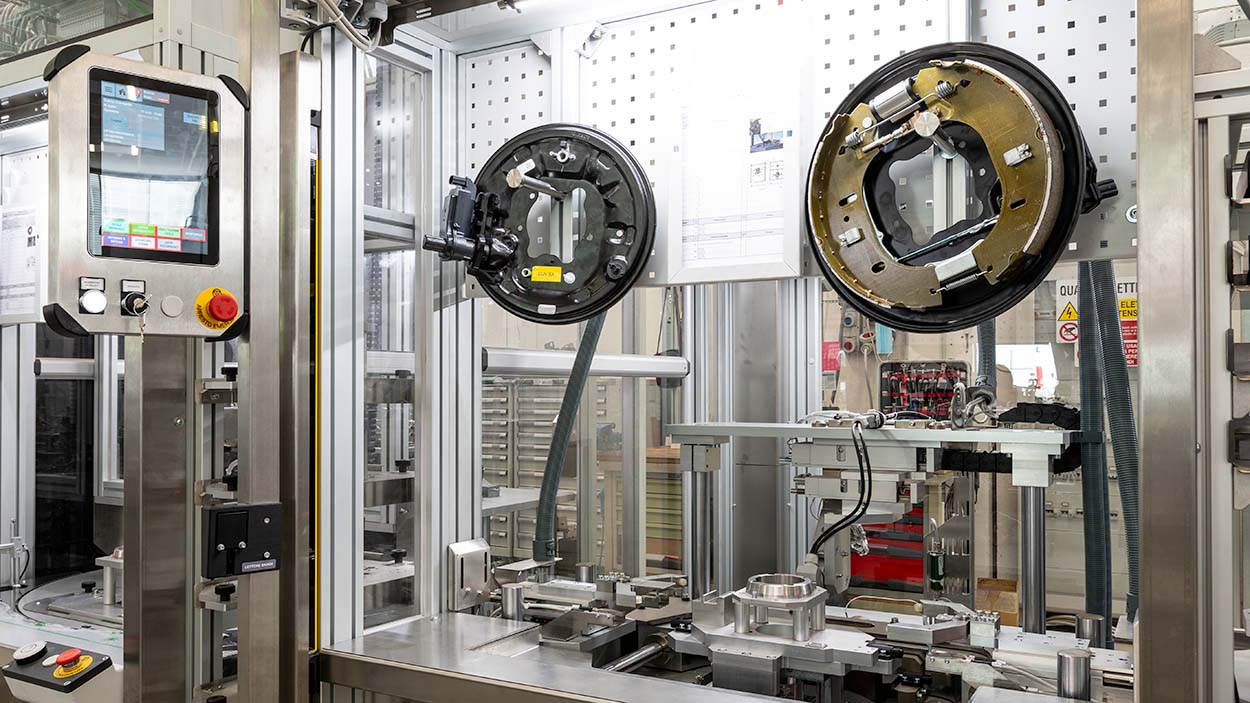

Based on the same bench and structure, Osai can realize rotary table, modular pallet line or manual bench. The ever-growing demand for flexibility in the production processes requires semi-automatic work benches to assemble and test products. OSAI offers customized solutions with a limited investment to automate manual operations.

Each module is a stand-alone machine, with independent PLC and HMI, ensuring efficient functionality and seamless coordination within fully automatic assembling and testing line.

It’s a scalable and flexible solution, who allow to add stations in later time without production stop. All benches are designed for manual loading parts in step_1 and robot automatic loading in step_2.

Able to ensure high quality production, with control over all phases of the production process, Osai creates lines designed to operate with maximum efficiency and precision, simultaneously managing drum brakes of different diameters.

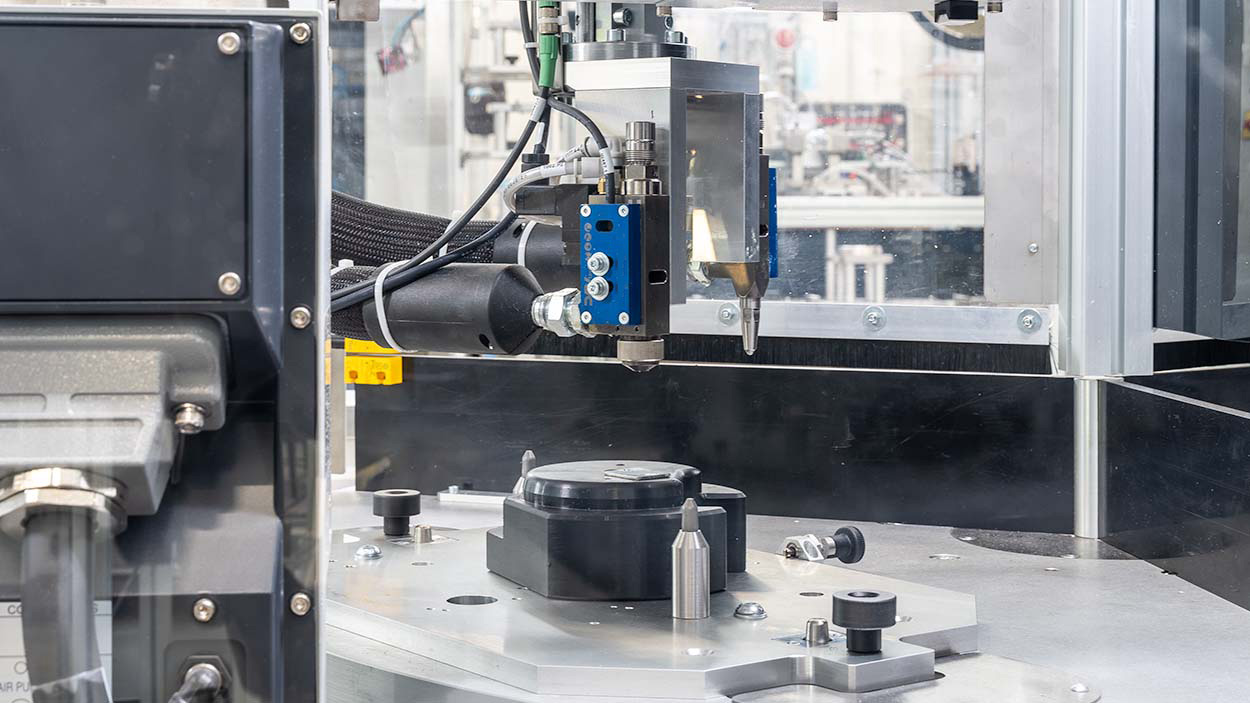

Osai lines are equipped with an integrated system to perform tightening, greasing, mechanical test, hysteresis test. Functional tests are performed to verify that each component meets the required operating standards and technical specifications. This ensures that each unit is fully functional and ready for use.

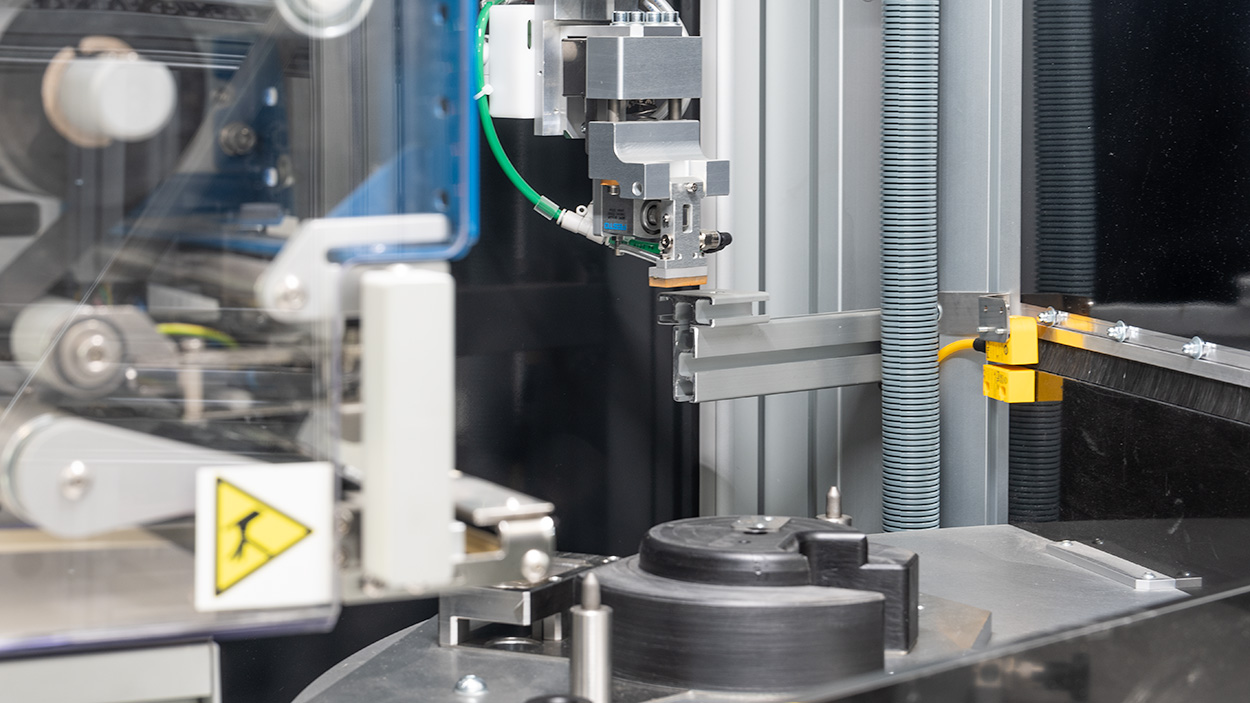

The optical tests to check, identify, and correct any defects can be conducted with the OSAI Inspection System, a customized hardware and software for high-definition image processing.

All process data are collected and associated with the unique part number of the individual product component. This allows the customer to monitor or track the required information. It provides a web report with IP address, protected by a password and accessible from PC and smartphone. The hardware architecture is flexible and adaptable to the interface and protocols of each Customer MES (Manufacturing Execution System). It can integrate a statistical analysis protocol for waste. Traceability can be investigated to provide a text or graphic report for the individual p / n, by lot, by date, by station, by value. Values can be exported in different formats: xml, csv, pdf, doc, etc; value’s graphic formatting can be customized according to the Customer specifications.

Scalable and Modular Line for Automotive Components

Osai flexible module systems are designed to adapt to a wide range of requirements. Whether you need a simple manual setup or a complex automated line, Osai systems can be customized to fit your needs.

Based on the same bench and structure, Osai can realize rotary table, modular pallet line or manual bench. The ever-growing demand for flexibility in the production processes requires semi-automatic work benches to assemble and test products. OSAI offers customized solutions with a limited investment to automate manual operations.

Each module is a stand-alone machine, with independent PLC and HMI, ensuring efficient functionality and seamless coordination within fully automatic assembling and testing line.

It’s a scalable and flexible solution, who allow to add stations in later time without production stop. All benches are designed for manual loading parts in step_1 and robot automatic loading in step_2.

Able to ensure high quality production, with control over all phases of the production process, Osai creates lines designed to operate with maximum efficiency and precision, simultaneously managing drum brakes of different diameters.

Osai lines are equipped with an integrated system to perform tightening, greasing, mechanical test, hysteresis test. Functional tests are performed to verify that each component meets the required operating standards and technical specifications. This ensures that each unit is fully functional and ready for use.

The optical tests to check, identify, and correct any defects can be conducted with the OSAI Inspection System, a customized hardware and software for high-definition image processing.

All process data are collected and associated with the unique part number of the individual product component. This allows the customer to monitor or track the required information. It provides a web report with IP address, protected by a password and accessible from PC and smartphone. The hardware architecture is flexible and adaptable to the interface and protocols of each Customer MES (Manufacturing Execution System). It can integrate a statistical analysis protocol for waste. Traceability can be investigated to provide a text or graphic report for the individual p / n, by lot, by date, by station, by value. Values can be exported in different formats: xml, csv, pdf, doc, etc; value’s graphic formatting can be customized according to the Customer specifications.