Automated Sorting and Stacking Solution

OSAI Automated Sorting and Stacking Solution is a top-class equipment for the module assembly benches.

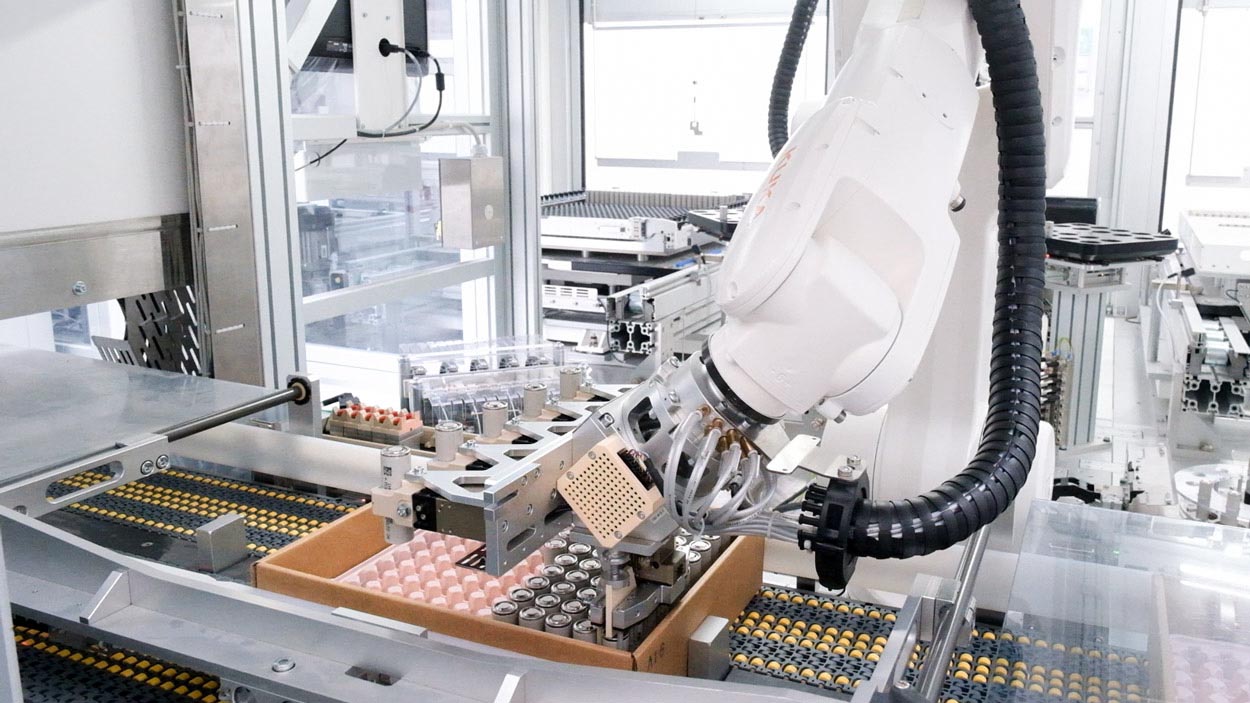

The process begins with the operator placing the pallet on the conveyor belt. This contains vertically arranged cells, which may have some positional tolerance within the packaging. Above the cells, a robotic arm equipped with a vision system captures an image of the box’s contents. This system guides the robot to accurately identify and pick the cells.

The robot picks five cells at a time and places them into a testing fixture, where the cells undergo individual testing—five at a time to optimize the cycle time, which is 4.5–5 seconds.

Testing and Tracing

Once deposited, the testing process begins. The cells are rotated for simultaneous reading of the five data Matrix ensuring traceability of the testing values for each cell.

Detailed testing includes:

- Polarity tests

- Internal resistance measurements (both AC impedance and DC resistance)

- Voltage readings

- Charge-discharge cycle tests (including charge and discharge time measurements)

Each test can also be performed individually if needed. The system records the results for every single cell, ensuring precise tracking of their performance metrics.

Sorting for Optimal Performance

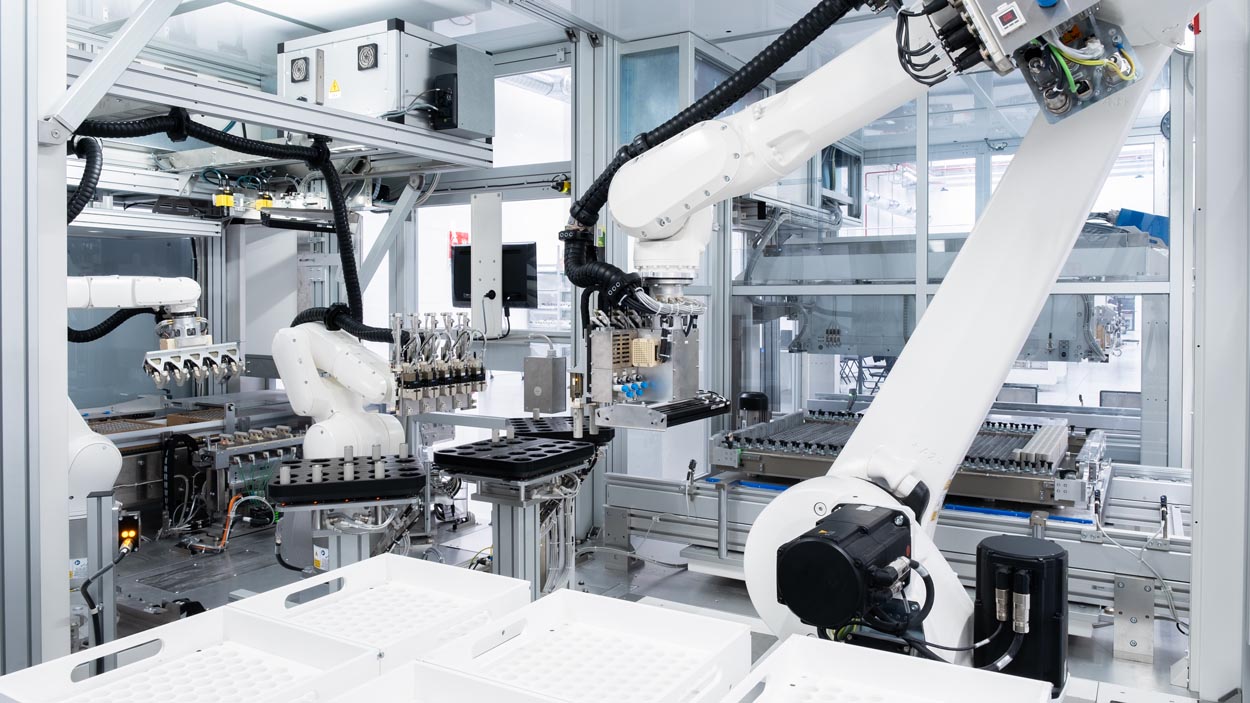

After testing, the system performs a sorting process. In order to guarantee a balanced module, there is a requirement to sort cells based on their capacity. Cell capacity information will be input within MES system. Once machine detects QR code and obtains capacity values, then decides where to allocate the cell. The robot sorts the cells into three designated parking positions based on their test results, grouping cells with homogeneous values.

Stacking and Module Assembly

The third robot handles the stacking process. It picks the sorted cells and assembles them into the module structure. This advanced system is capable of simultaneously assembling three battery modules, streamlining the production process and ensuring high efficiency.

Flexible automation is a production system based on the use of industrial robots, capable of allowing rapid production changes. OSAI Automated Sorting and Stacking Solution can be adapted according to the product.

Automated Sorting and Stacking Solution

OSAI Automated Sorting and Stacking Solution is a top-class equipment for the module assembly benches.

The process begins with the operator placing the pallet on the conveyor belt. This contains vertically arranged cells, which may have some positional tolerance within the packaging. Above the cells, a robotic arm equipped with a vision system captures an image of the box’s contents. This system guides the robot to accurately identify and pick the cells.

The robot picks five cells at a time and places them into a testing fixture, where the cells undergo individual testing—five at a time to optimize the cycle time, which is 4.5–5 seconds.

Testing and Tracing

Once deposited, the testing process begins. The cells are rotated for simultaneous reading of the five data Matrix ensuring traceability of the testing values for each cell.

Detailed testing includes:

- Polarity tests

- Internal resistance measurements (both AC impedance and DC resistance)

- Voltage readings

- Charge-discharge cycle tests (including charge and discharge time measurements)

Each test can also be performed individually if needed. The system records the results for every single cell, ensuring precise tracking of their performance metrics.

Sorting for Optimal Performance

After testing, the system performs a sorting process. In order to guarantee a balanced module, there is a requirement to sort cells based on their capacity. Cell capacity information will be input within MES system. Once machine detects QR code and obtains capacity values, then decides where to allocate the cell. The robot sorts the cells into three designated parking positions based on their test results, grouping cells with homogeneous values.

Stacking and Module Assembly

The third robot handles the stacking process. It picks the sorted cells and assembles them into the module structure. This advanced system is capable of simultaneously assembling three battery modules, streamlining the production process and ensuring high efficiency.

Flexible automation is a production system based on the use of industrial robots, capable of allowing rapid production changes. OSAI Automated Sorting and Stacking Solution can be adapted according to the product.