Automotive.

Automotive.

Solution for driving Innovation, shaping the future.

With a deep understanding of the unique requirements and challenges faced by automotive manufacturers, we develop innovative and efficient solutions to streamline the production process and ensure the highest quality standards with integrating advanced systems and technologies to enhance safety and user experience.

The automotive industry is a vast sector that encompasses the design, development, manufacturing, marketing, and sales of vehicles, including cars, trucks, buses, and motorcycles, as well as their associated components and systems.

Energy efficiency, alternative fuels, automated vehicles, and transport systems. Technological advances have made innovations in electric engine components of main importance. This brings inevitable changes in the supply chains, given the varying innovative capabilities of several component suppliers.

Innovation is a driving force in the automotive industry, with ongoing advancements in areas such as electrification, autonomous driving, connectivity, and lightweight materials.

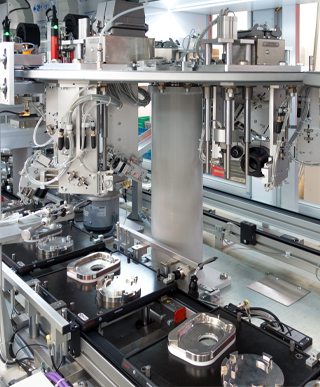

Vehicle manufacturing involves a complex process that includes stamping, welding, painting, assembly, and quality control. Components such as engines, transmissions, chassis, and electrical systems are produced by specialized suppliers and integrated into the final vehicle assembly.

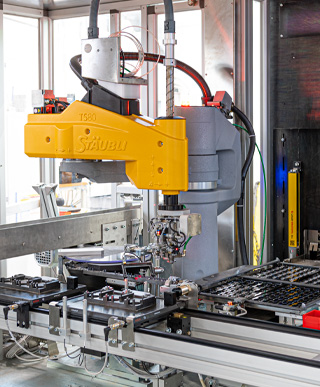

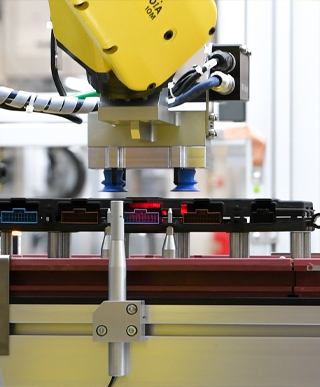

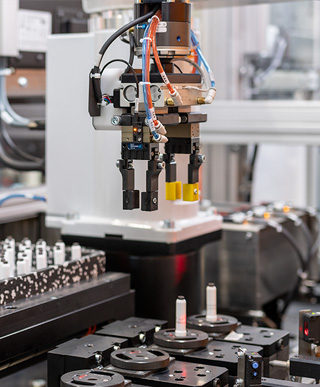

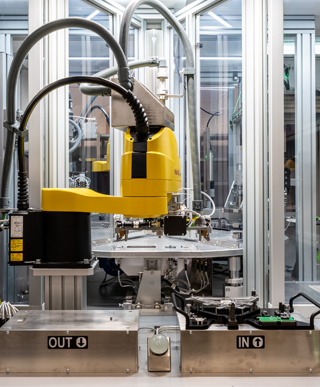

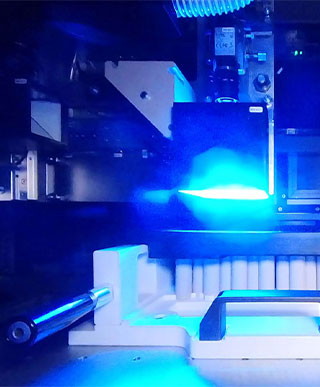

Osai systems are extremely durable with the chance to follow the technical evolution of the product and flexible re-tooling. Osai is an ideal partner to support the development phases of car and electric vehicle components with solutions for assembly, Laser welding and marking, battery pack testing, tailor made assembly and testing lines.

Solution for driving Innovation, shaping the future.

With a deep understanding of the unique requirements and challenges faced by automotive manufacturers, we develop innovative and efficient solutions to streamline the production process and ensure the highest quality standards with integrating advanced systems and technologies to enhance safety and user experience.

The automotive industry is a vast sector that encompasses the design, development, manufacturing, marketing, and sales of vehicles, including cars, trucks, buses, and motorcycles, as well as their associated components and systems.

Energy efficiency, alternative fuels, automated vehicles, and transport systems. Technological advances have made innovations in electric engine components of main importance. This brings inevitable changes in the supply chains, given the varying innovative capabilities of several component suppliers.

Innovation is a driving force in the automotive industry, with ongoing advancements in areas such as electrification, autonomous driving, connectivity, and lightweight materials.

Vehicle manufacturing involves a complex process that includes stamping, welding, painting, assembly, and quality control. Components such as engines, transmissions, chassis, and electrical systems are produced by specialized suppliers and integrated into the final vehicle assembly.

Osai systems are extremely durable with the chance to follow the technical evolution of the product and flexible re-tooling. Osai is an ideal partner to support the development phases of car and electric vehicle components with solutions for assembly, Laser welding and marking, battery pack testing, tailor made assembly and testing lines.