Innovation and Reliability for Mass Production

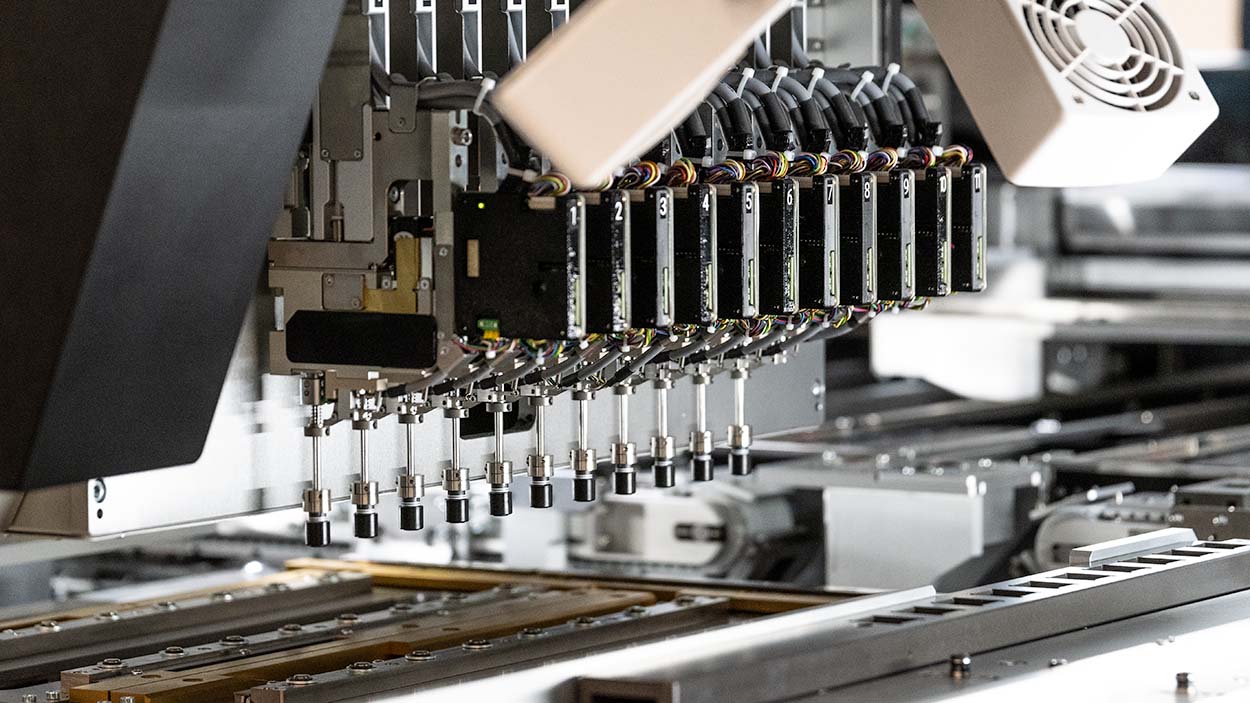

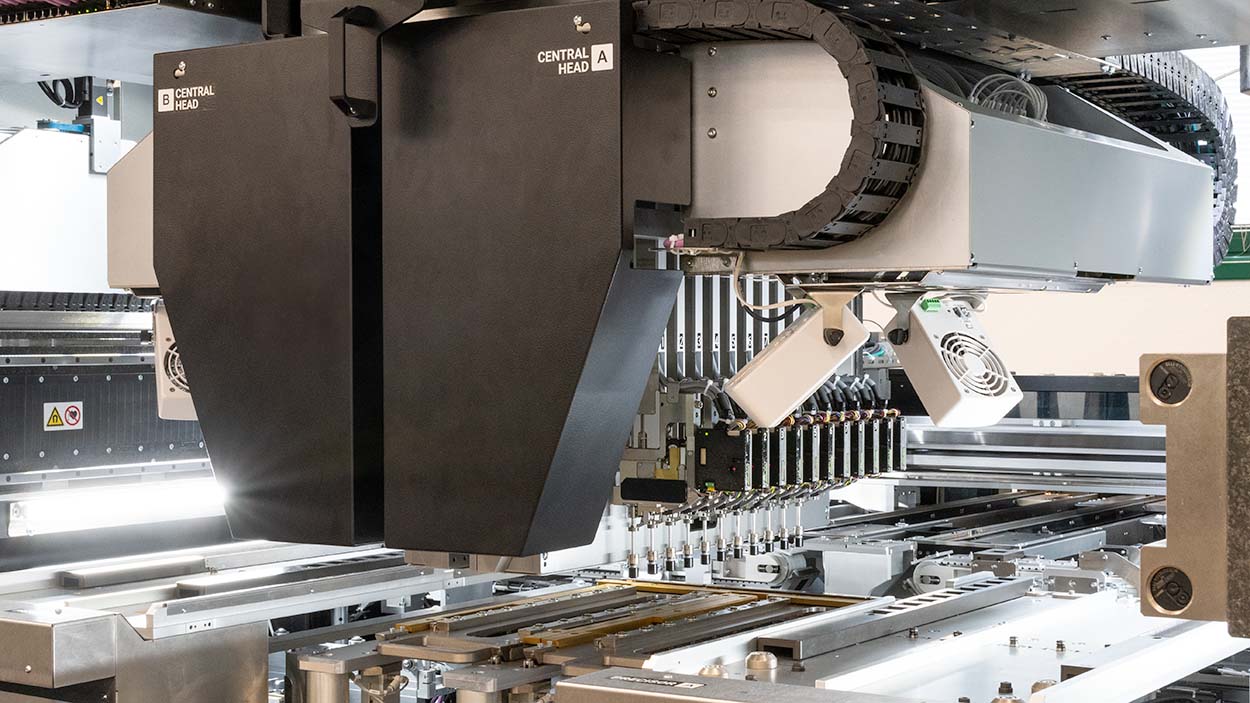

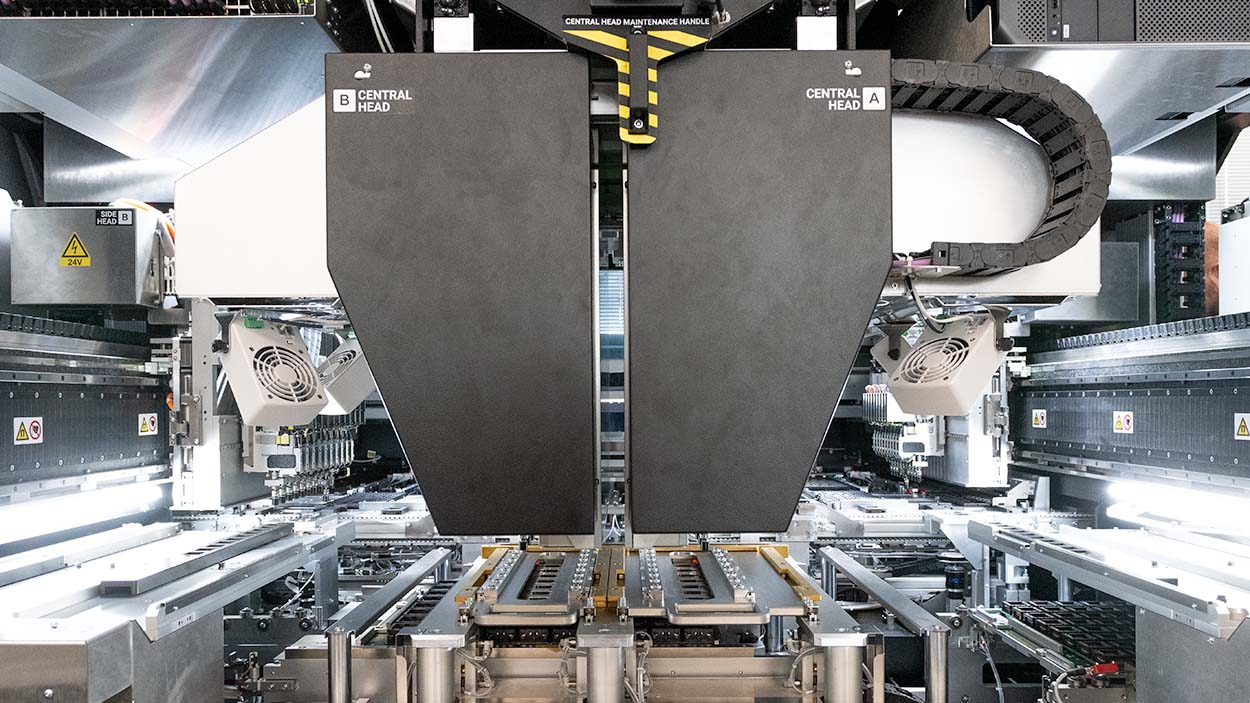

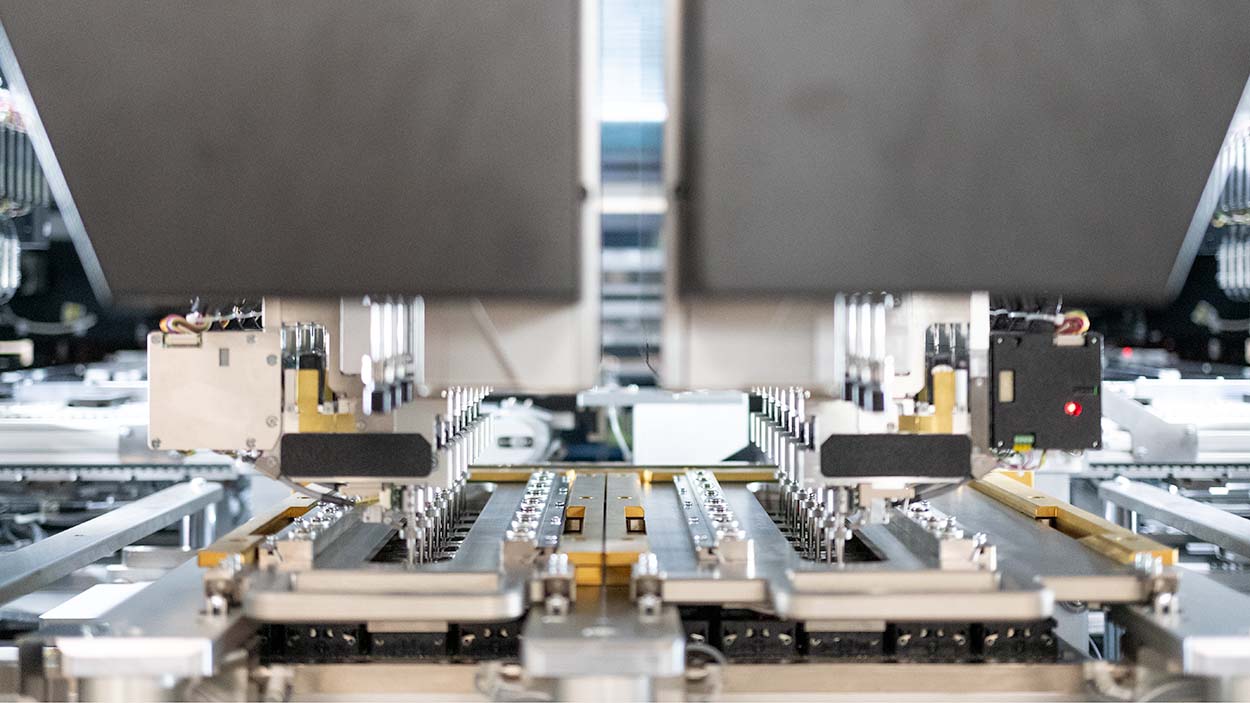

Discover NeoBLU, the next-generation Burn-In Loader/Unloader/Sorter, designed to deliver extreme mass production at high speeds with complete reliability.

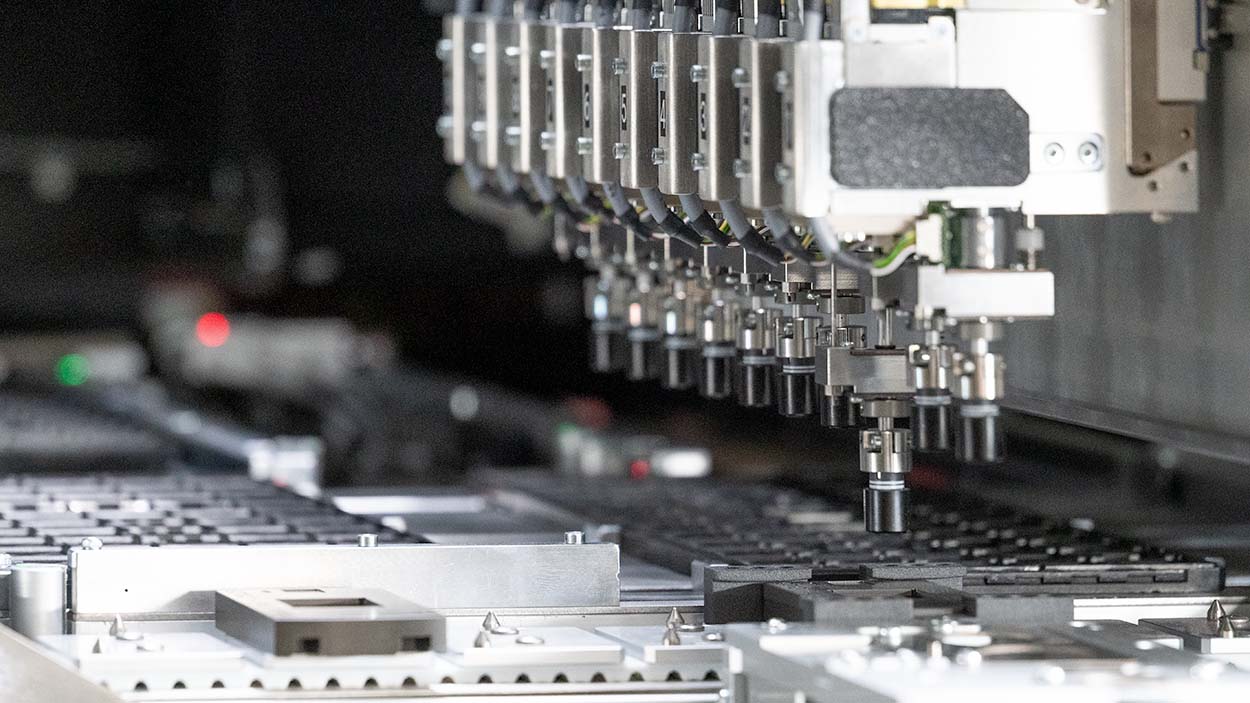

With robust mechanics, exceptional movement precision, and superior performance in speed and acceleration, NeoBLU can handle up to 20.000 units per hour (UPH).

- High Performance: NeoBLU offers a handling capacity of 20.000 units per hour, perfect for production environments demanding maximum efficiency.

- Reliability and Precision: Built with robust mechanics and highly accurate movement precision, ensuring optimal performance in every work cycle.

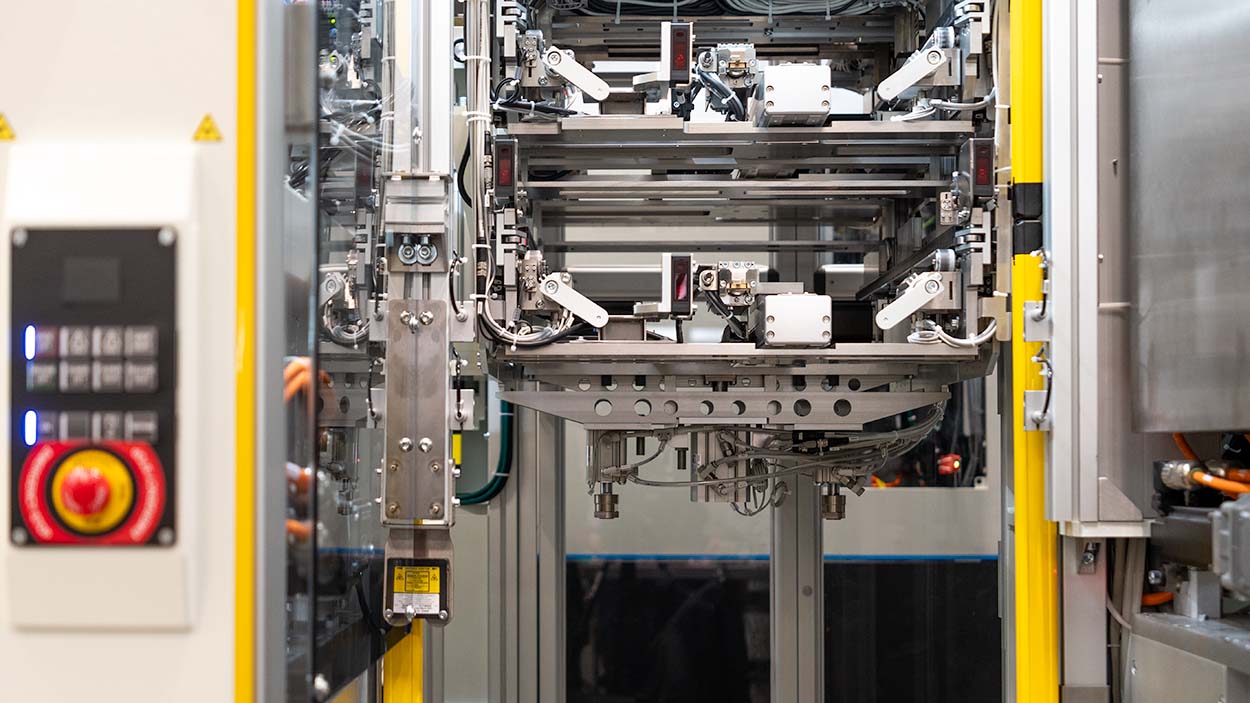

- Advanced Automation: Designed for high-level automated environments, NeoBLU is “Lights-off factory ready”, minimizing human intervention.

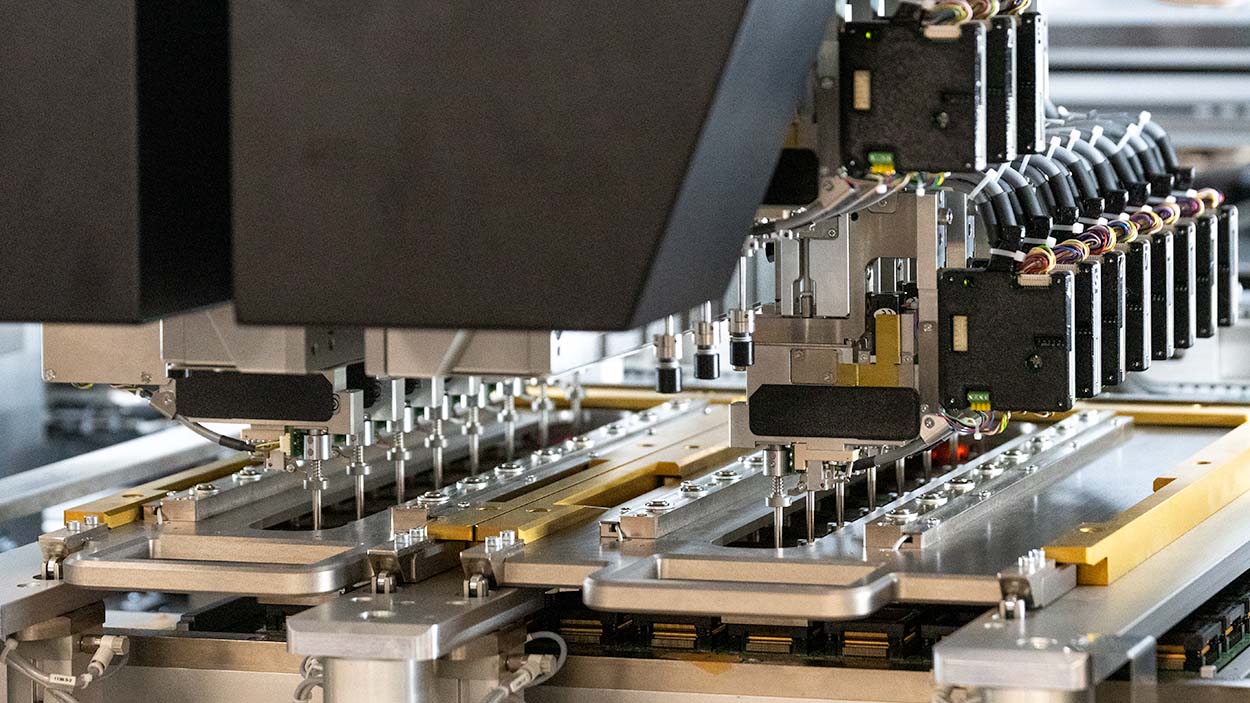

- Anti-Mixing Systems: Equipped with advanced vision systems and redundant controls, NeoBLU ensures total and continuous traceability of all handled units, managing multiple production lots simultaneously.

- Total Integration: Native support for Secs-Gem, MES integration, and automatic loading and unloading devices make NeoBLU a fully integrated solution.

- Seamless Product Changeover: With three onboard conversion kits, a simple recipe change is all it takes to start new production without impacting productivity.

- Fully Automated Burn-In Board Loading: With dedicated add-ons, NeoBLU can load Burn-In Boards directly from trolleys fully automatically, managing DUTs tray-to-tray.

Advanced Software

NeoBLU features an advanced self-diagnostic software that allows for automatic corrections, guiding operators and maintenance personnel in a straightforward and functional way. Additionally, the software provides advanced statistical processing of production data and system performance, delivering valuable insights for production planning and system optimization.

Choose NeoBLU for reliable, fast, and fully automated mass production. Maximize the potential of your production line with this innovative and cutting-edge solution.

Innovation and Reliability for Mass Production

Discover NeoBLU, the next-generation Burn-In Loader/Unloader/Sorter, designed to deliver extreme mass production at high speeds with complete reliability.

With robust mechanics, exceptional movement precision, and superior performance in speed and acceleration, NeoBLU can handle up to 20.000 units per hour (UPH).

- High Performance: NeoBLU offers a handling capacity of 20.000 units per hour, perfect for production environments demanding maximum efficiency.

- Reliability and Precision: Built with robust mechanics and highly accurate movement precision, ensuring optimal performance in every work cycle.

- Advanced Automation: Designed for high-level automated environments, NeoBLU is “Lights-off factory ready”, minimizing human intervention.

- Anti-Mixing Systems: Equipped with advanced vision systems and redundant controls, NeoBLU ensures total and continuous traceability of all handled units, managing multiple production lots simultaneously.

- Total Integration: Native support for Secs-Gem, MES integration, and automatic loading and unloading devices make NeoBLU a fully integrated solution.

- Seamless Product Changeover: With three onboard conversion kits, a simple recipe change is all it takes to start new production without impacting productivity.

- Fully Automated Burn-In Board Loading: With dedicated add-ons, NeoBLU can load Burn-In Boards directly from trolleys fully automatically, managing DUTs tray-to-tray.

Advanced Software

NeoBLU features an advanced self-diagnostic software that allows for automatic corrections, guiding operators and maintenance personnel in a straightforward and functional way. Additionally, the software provides advanced statistical processing of production data and system performance, delivering valuable insights for production planning and system optimization.

Choose NeoBLU for reliable, fast, and fully automated mass production. Maximize the potential of your production line with this innovative and cutting-edge solution.