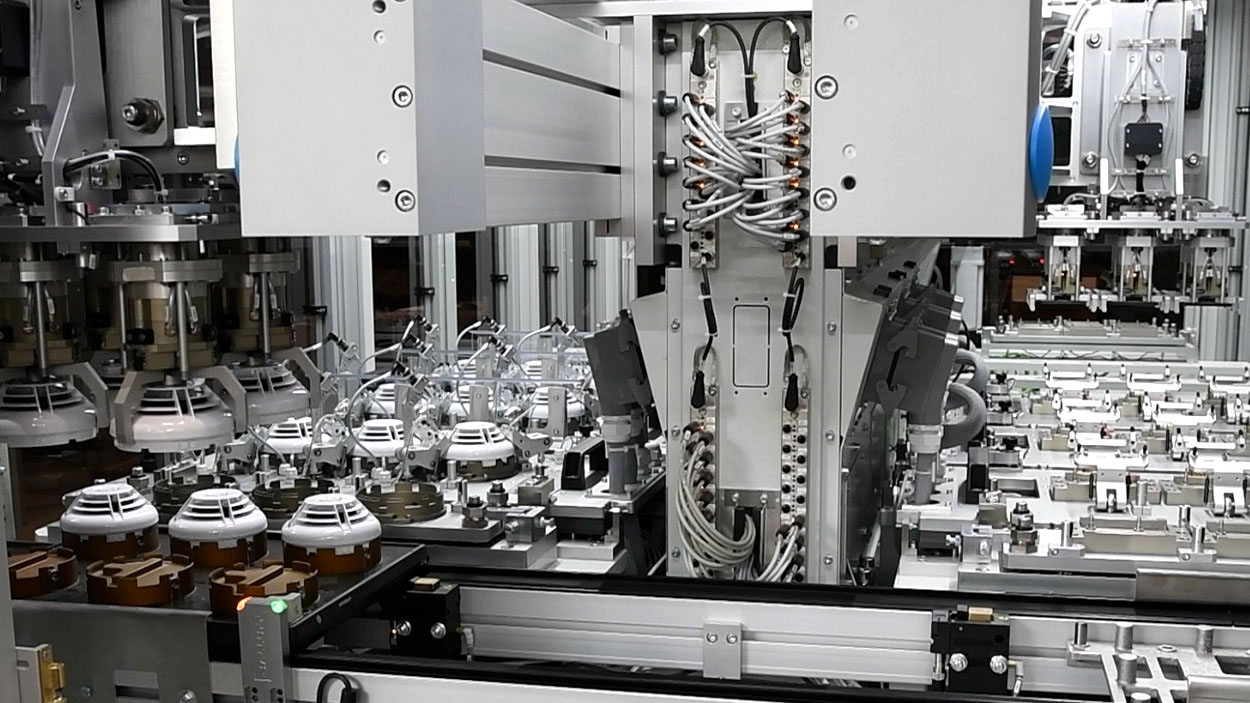

Smoke Detectors Assembly Line

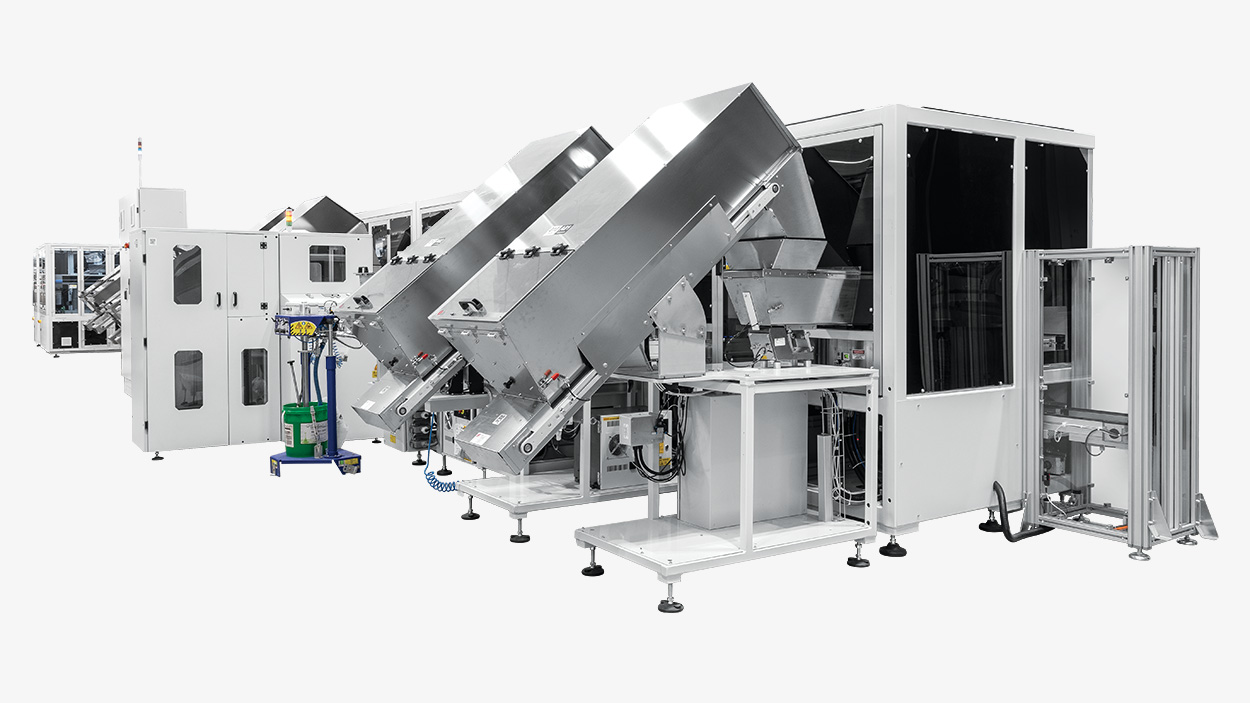

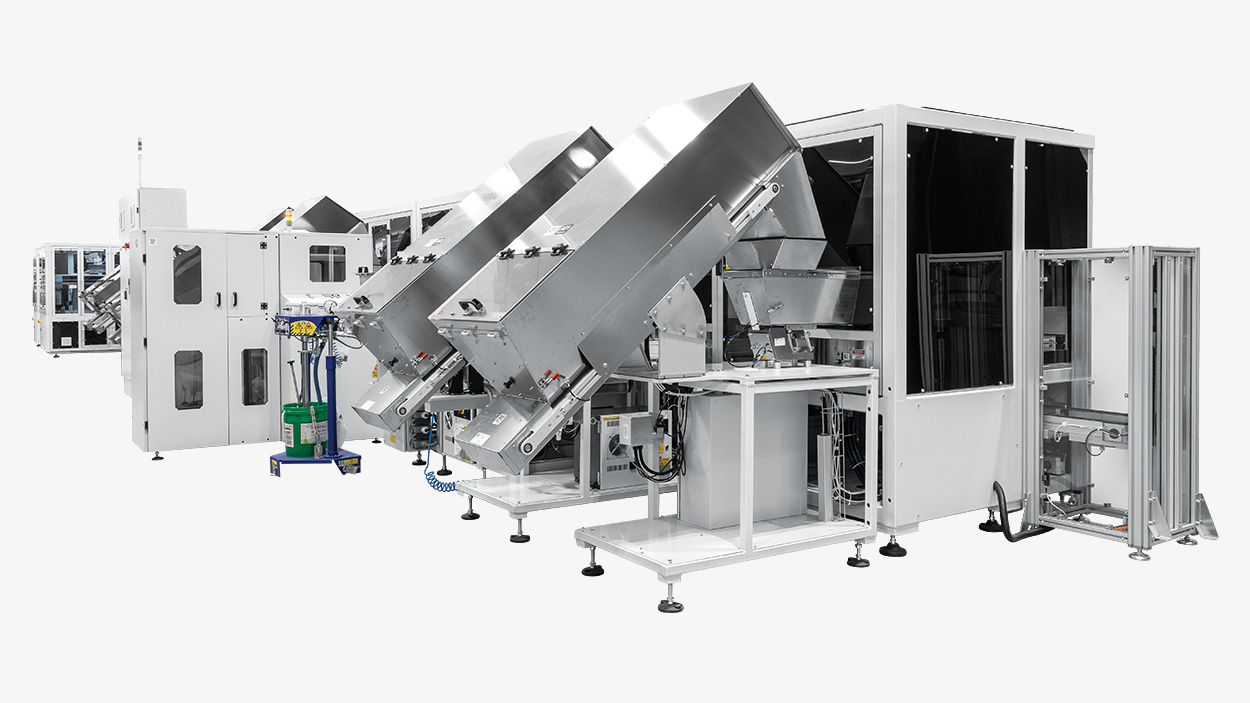

Smoke Detectors Assembly Line is a fully automatic assembling, testing and packaging line.

The line can manage, without manual resetting, 4 product families with different geometries which, in turn, generate a range of over 200 codes, guaranteeing a productivity of 900 parts per hour (1 every 4 seconds).

Being an Industry 4.0 asset, the batch changes are managed by PLC recipes loaded by the customer’s MES – Manufacturing Execution System and thanks to a two-way communication the line generates and returns statistical and quality reports which can be consulted remotely.

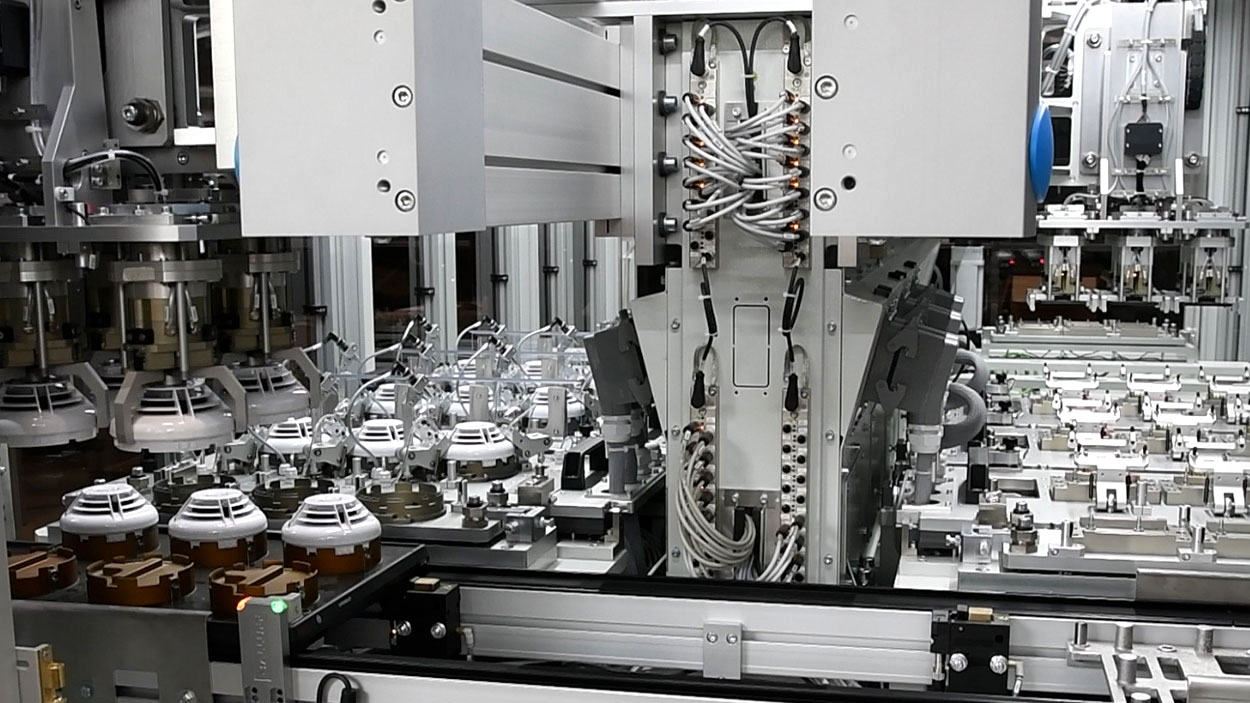

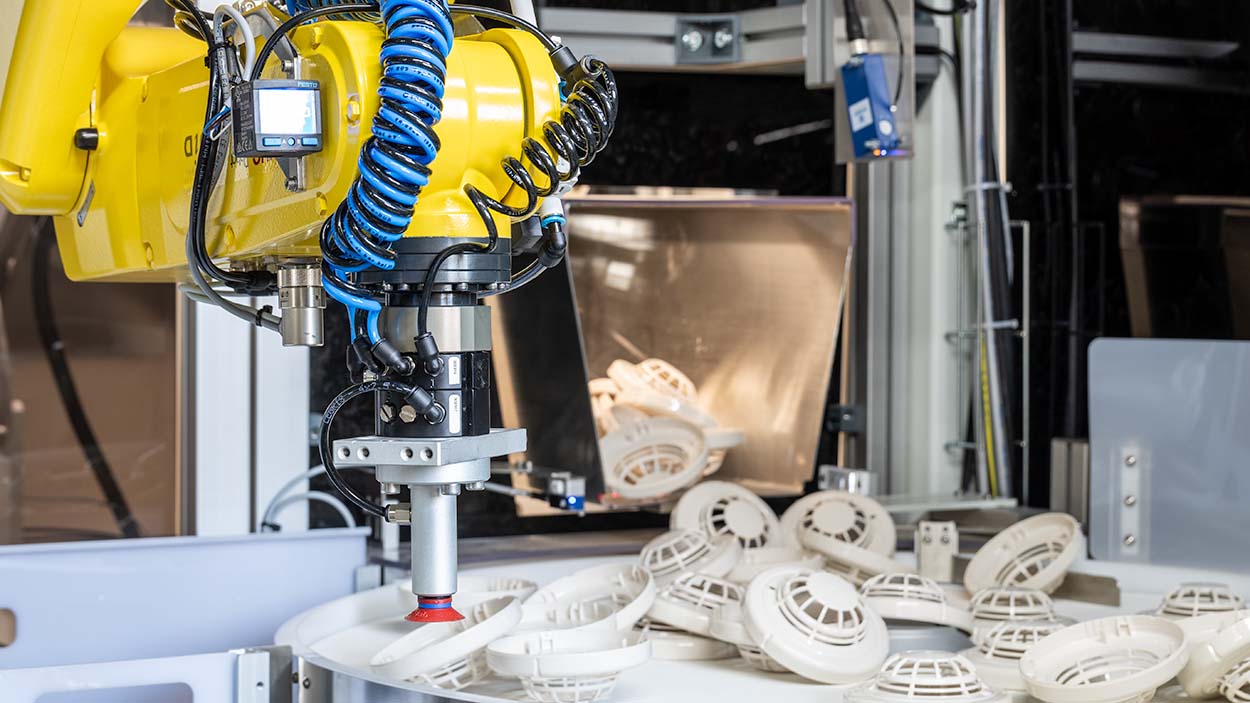

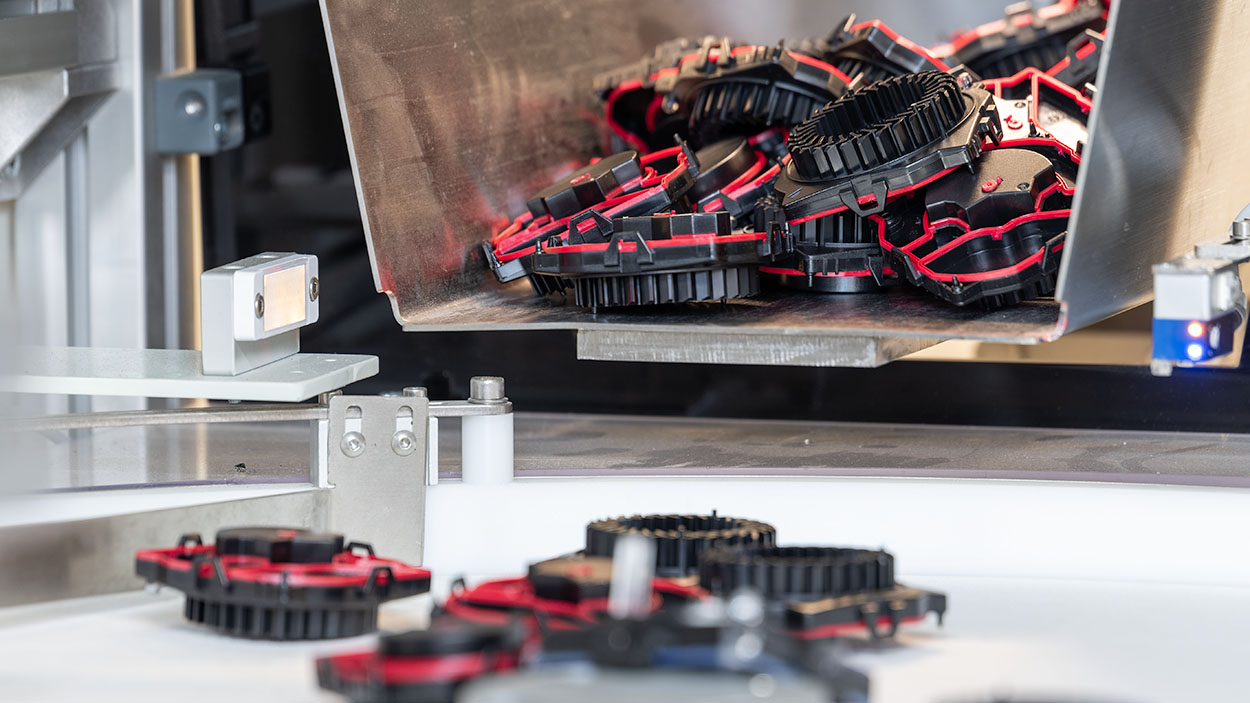

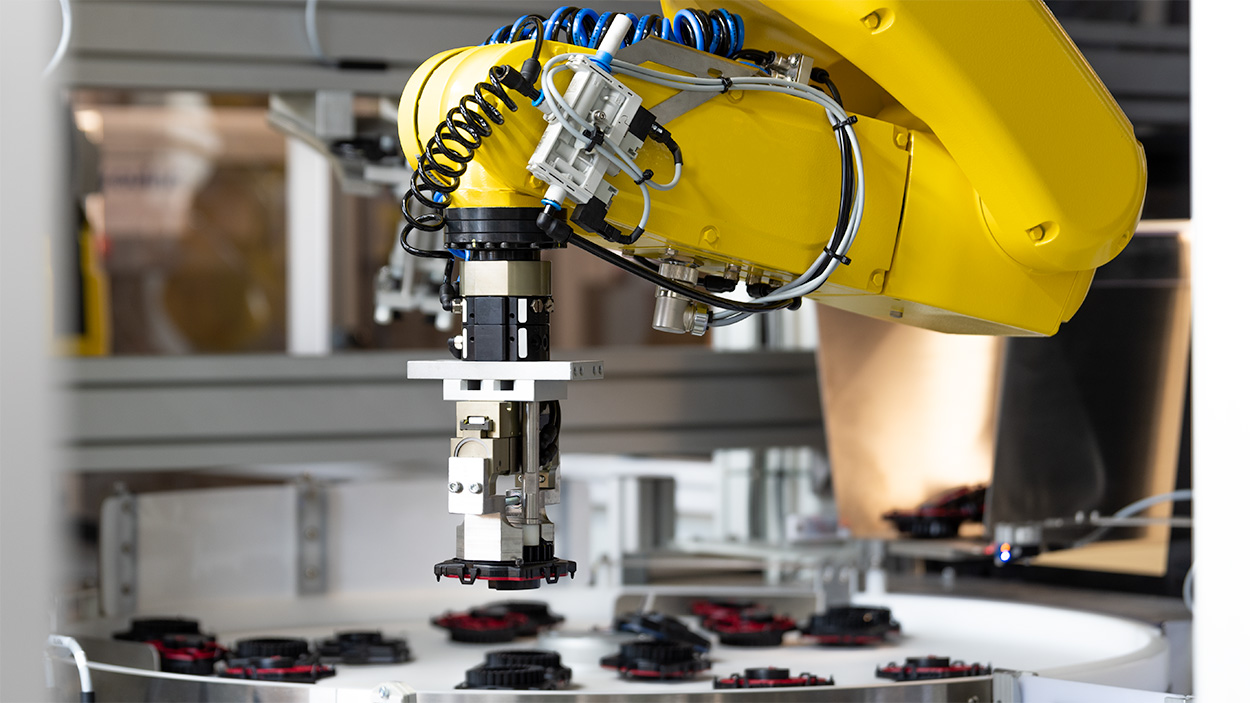

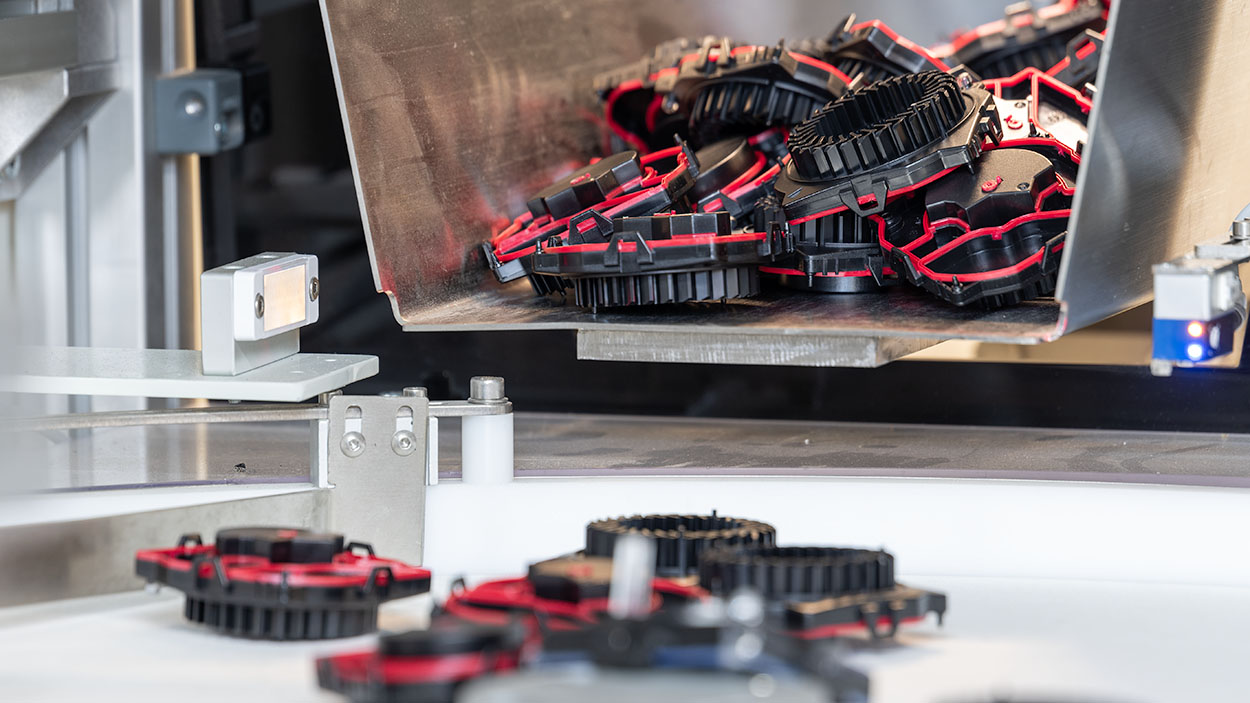

Smoke Detectors Assembly Line has several assembly and testing stations. It is equipped with a pallet transport with six figures each, where each station can work on three to six components simultaneously. Several robots, both scara and 6-axis, are installed on the line, which by means of multigrippers pick up the parts from the feeding systems and load them onto the pallet. To reduce the time to market, the electronic board in the sensor is depanalled just in sequence directly by NeoRouter Modula.

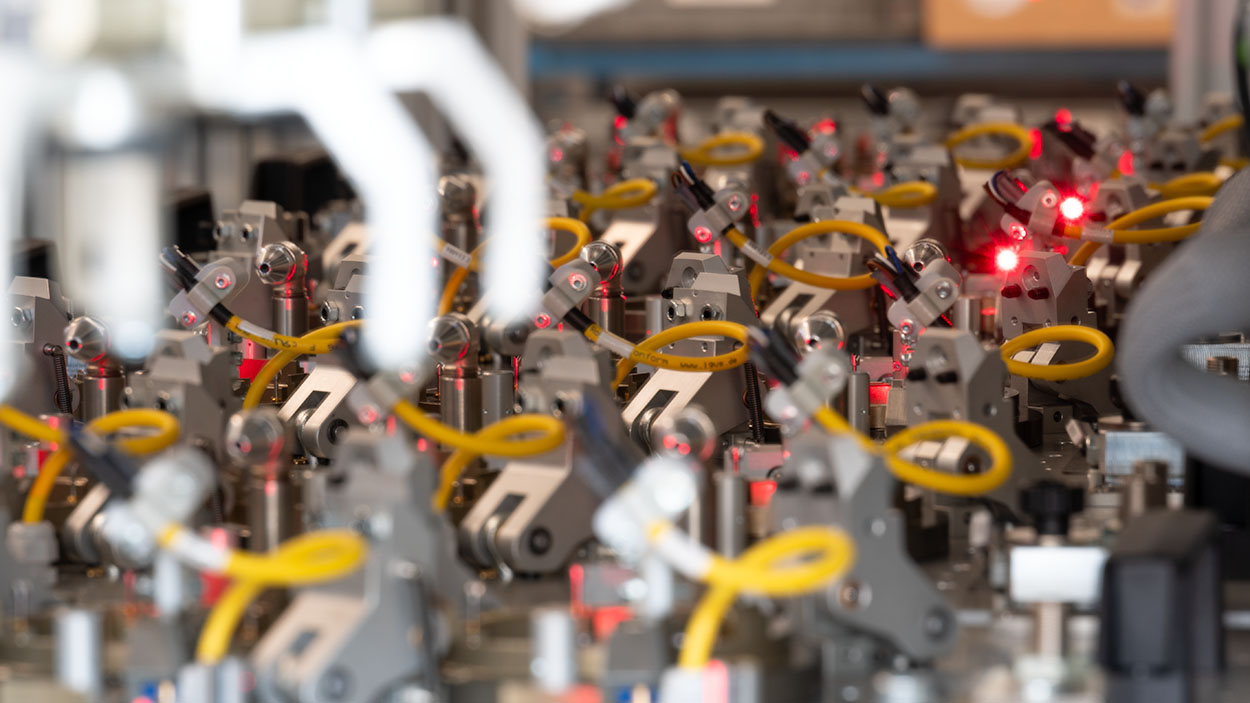

Welded onto each board, the thermistor detects the abnormal temperature and sends the fire signal to the downstream control unit. Besides, a thermistor position recovery and centring devices specially designed for this application, allow the robot to insert subsequent elements avoiding damage which would lead to product malfunction.

After assembly, the sensor enters the EOL – End of Life bay, where the working conditions of the product are simulated. Every 30 seconds we check the component at multiple stations. This is done by dynamically simulating different conditions occurring during a fire, verifying and calibrating it.

All test values of the individual ID are recorded and saved on the MES. Compliant components are Laser-marked with a unique QR-Code and fed into the primary and secondary packaging line. From their reading, the customer can trace all process data such as batch, test values and BOM – Bill of Materials. The traceability system also has a human error proof function.

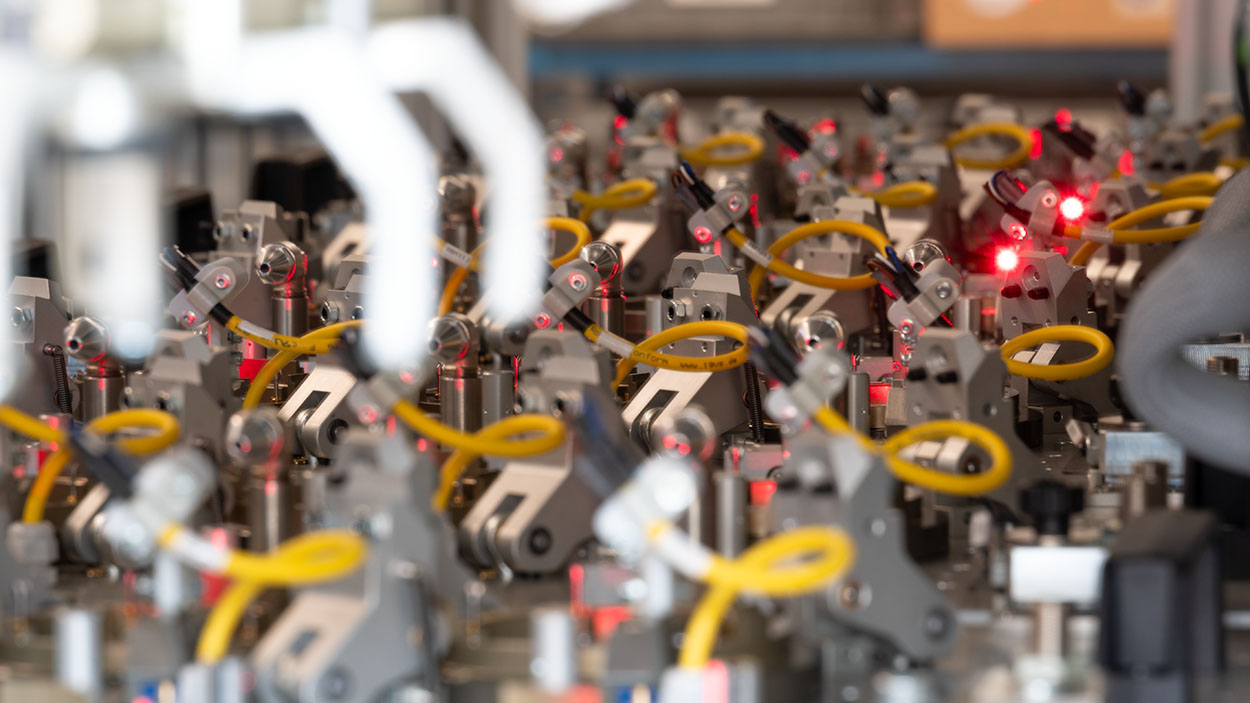

Smoke Detectors Assembly Line

Smoke Detectors Assembly Line is a fully automatic assembling, testing and packaging line.

The line can manage, without manual resetting, 4 product families with different geometries which, in turn, generate a range of over 200 codes, guaranteeing a productivity of 900 parts per hour (1 every 4 seconds).

Being an Industry 4.0 asset, the batch changes are managed by PLC recipes loaded by the customer’s MES – Manufacturing Execution System and thanks to a two-way communication the line generates and returns statistical and quality reports which can be consulted remotely.

Smoke Detectors Assembly Line has several assembly and testing stations. It is equipped with a pallet transport with six figures each, where each station can work on three to six components simultaneously. Several robots, both scara and 6-axis, are installed on the line, which by means of multigrippers pick up the parts from the feeding systems and load them onto the pallet. To reduce the time to market, the electronic board in the sensor is depanalled just in sequence directly by NeoRouter Modula.

Welded onto each board, the thermistor detects the abnormal temperature and sends the fire signal to the downstream control unit. Besides, a thermistor position recovery and centring devices specially designed for this application, allow the robot to insert subsequent elements avoiding damage which would lead to product malfunction.

After assembly, the sensor enters the EOL – End of Life bay, where the working conditions of the product are simulated. Every 30 seconds we check the component at multiple stations. This is done by dynamically simulating different conditions occurring during a fire, verifying and calibrating it.

All test values of the individual ID are recorded and saved on the MES. Compliant components are Laser-marked with a unique QR-Code and fed into the primary and secondary packaging line. From their reading, the customer can trace all process data such as batch, test values and BOM – Bill of Materials. The traceability system also has a human error proof function.