Thermal paste and UV glue dispensing

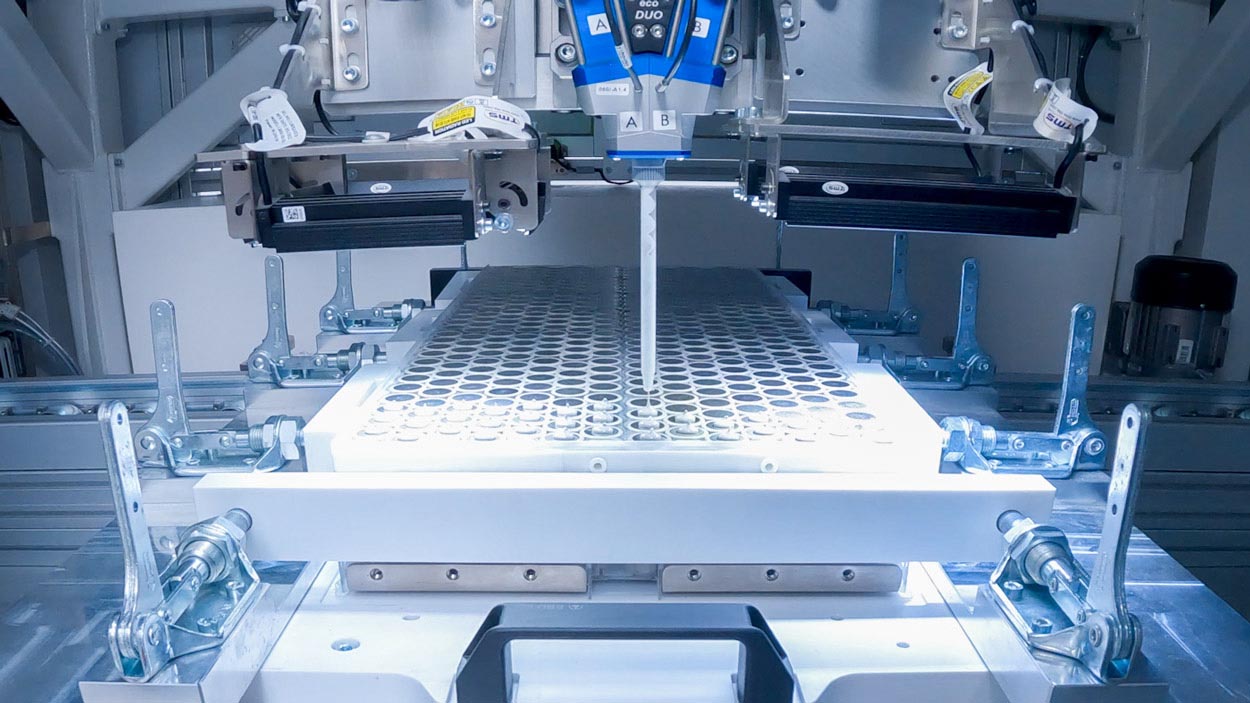

OSAI process involves dedicated stations for dispensing thermal paste and UV glue, ensuring precision, control, and traceability at every stage.

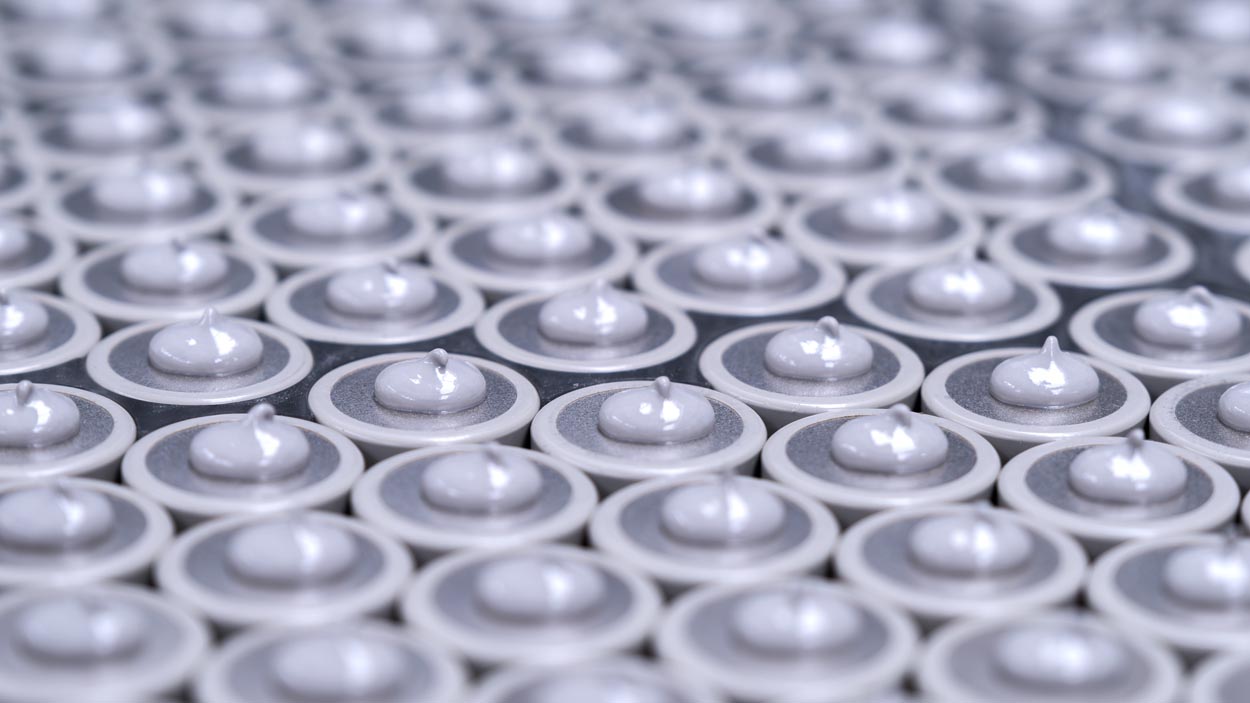

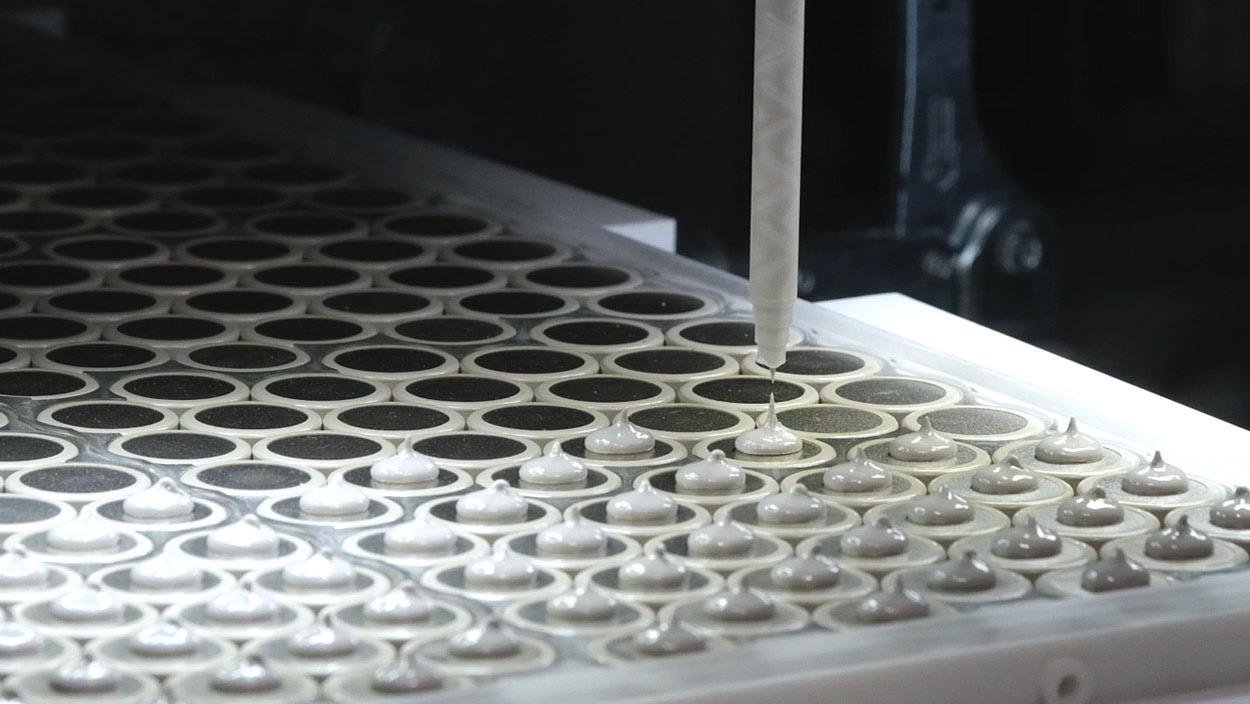

Thermal Paste Dispensing Station

The pallet, containing the components, is transported to the workstation where a cartesian robot (x-y-z) operates the thermal paste dispensing unit.

- Initial inspection: A camera verifies the actual position of the cells compared to the nominal position, ensuring accurate alignment.

- Mixing: Since the thermal paste is a two-component material, a mixing head combines the two components just before dispensing.

- Dispensing: The paste is applied with precision to predefined points. Each operation takes approximately four seconds.

- Final inspection: A second camera checks that the paste has been applied in the correct location and in the appropriate quantity over the cells.

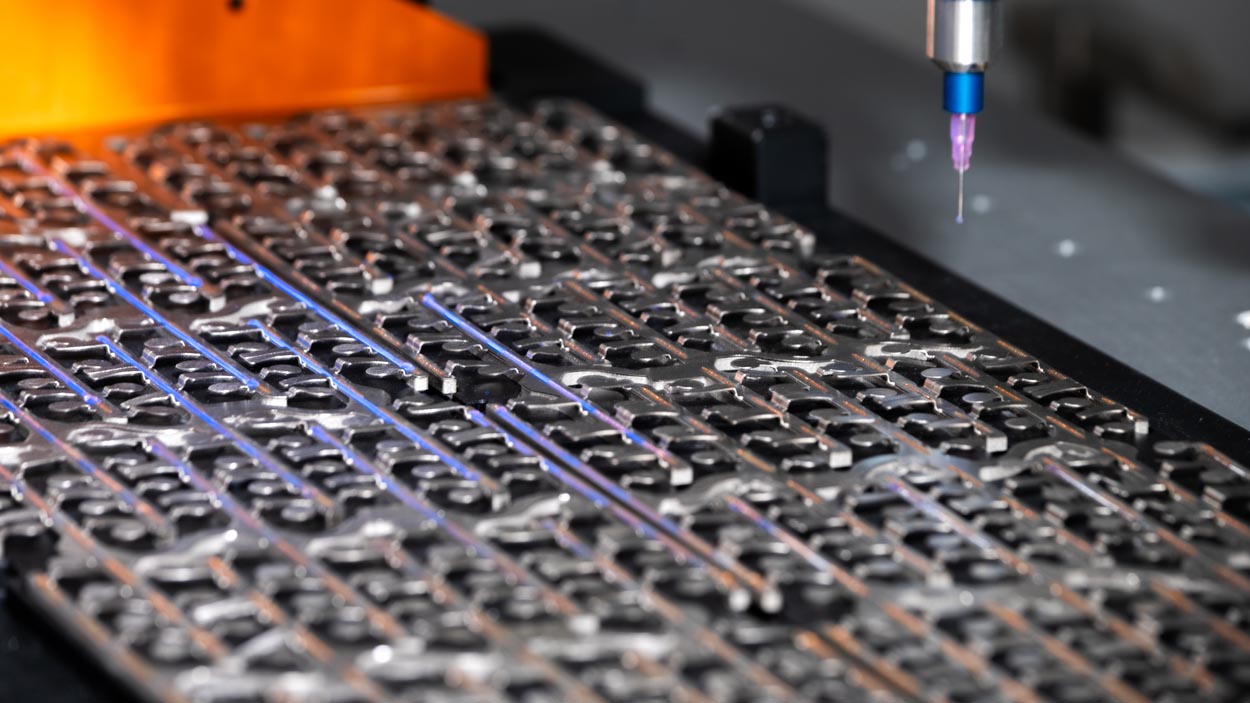

UV Glue Dispensing Station

The UV glue station follows a similar process but is adapted to the properties of the adhesive:

- Initial inspection: A camera verifies the actual position of the cells compared to the nominal position, ensuring accurate alignment.

- Direct dispensing: Since UV glue is single component, no mixing is required, and the system directly dispenses the adhesive at designated points.

- Visual inspection: As the glue is transparent and liquid, an ultraviolet lamp illuminates the area after dispensing to verify proper application.

- Process: The cycle includes inspection, dispensing, ensuring precision and consistency.

Traceability and Manual Interaction

Manual stations, equipped with guided tools, are integrated into the process for tasks such as welding and dispensing. Using a barcode reader, operators can scan the pallet to identify the specific module and its contained cells. This traceability system ensures complete control throughout all operations.

Flexible automation is a production system based on the use of industrial robots, capable of allowing rapid production changes. OSAI thermal paste and UV glue dispensing solution can be adapted according to the product.

Thermal paste and UV glue dispensing

OSAI process involves dedicated stations for dispensing thermal paste and UV glue, ensuring precision, control, and traceability at every stage.

Thermal Paste Dispensing Station

The pallet, containing the components, is transported to the workstation where a cartesian robot (x-y-z) operates the thermal paste dispensing unit.

- Initial inspection: A camera verifies the actual position of the cells compared to the nominal position, ensuring accurate alignment.

- Mixing: Since the thermal paste is a two-component material, a mixing head combines the two components just before dispensing.

- Dispensing: The paste is applied with precision to predefined points. Each operation takes approximately four seconds.

- Final inspection: A second camera checks that the paste has been applied in the correct location and in the appropriate quantity over the cells.

UV Glue Dispensing Station

The UV glue station follows a similar process but is adapted to the properties of the adhesive:

- Initial inspection: A camera verifies the actual position of the cells compared to the nominal position, ensuring accurate alignment.

- Direct dispensing: Since UV glue is single component, no mixing is required, and the system directly dispenses the adhesive at designated points.

- Visual inspection: As the glue is transparent and liquid, an ultraviolet lamp illuminates the area after dispensing to verify proper application.

- Process: The cycle includes inspection, dispensing, ensuring precision and consistency.

Traceability and Manual Interaction

Manual stations, equipped with guided tools, are integrated into the process for tasks such as welding and dispensing. Using a barcode reader, operators can scan the pallet to identify the specific module and its contained cells. This traceability system ensures complete control throughout all operations.

Flexible automation is a production system based on the use of industrial robots, capable of allowing rapid production changes. OSAI thermal paste and UV glue dispensing solution can be adapted according to the product.