Mass Production Test Handler for Power Module

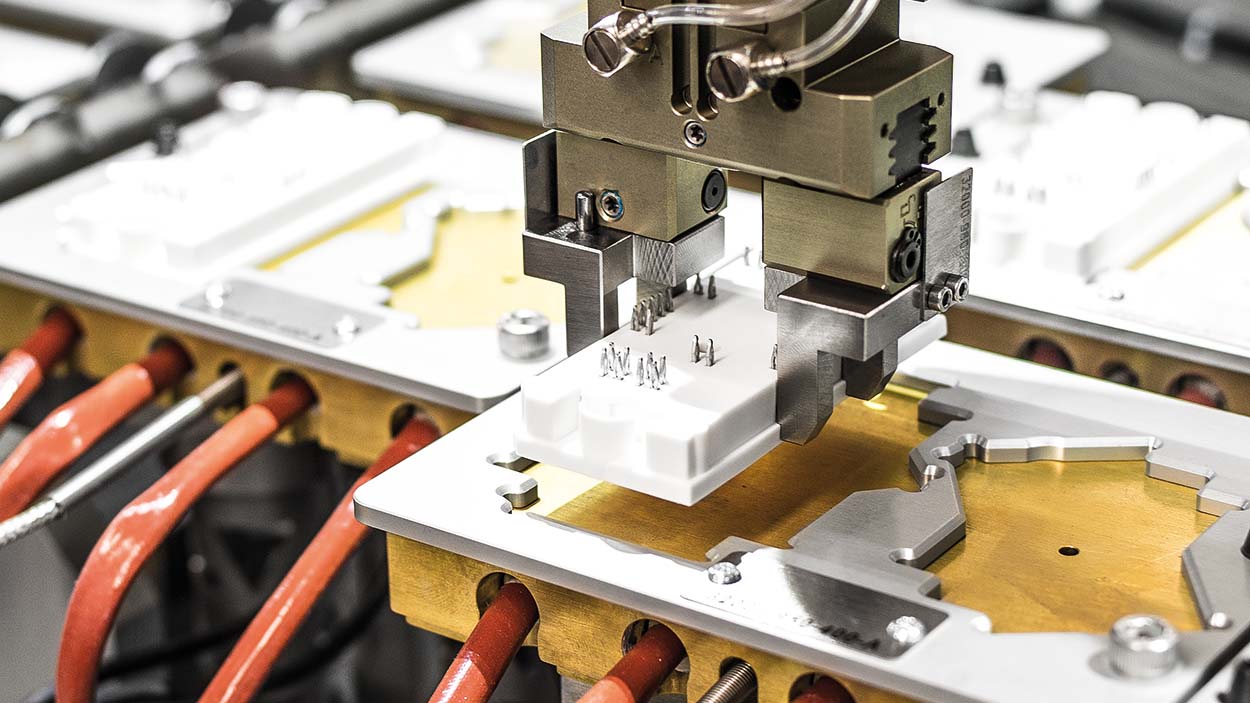

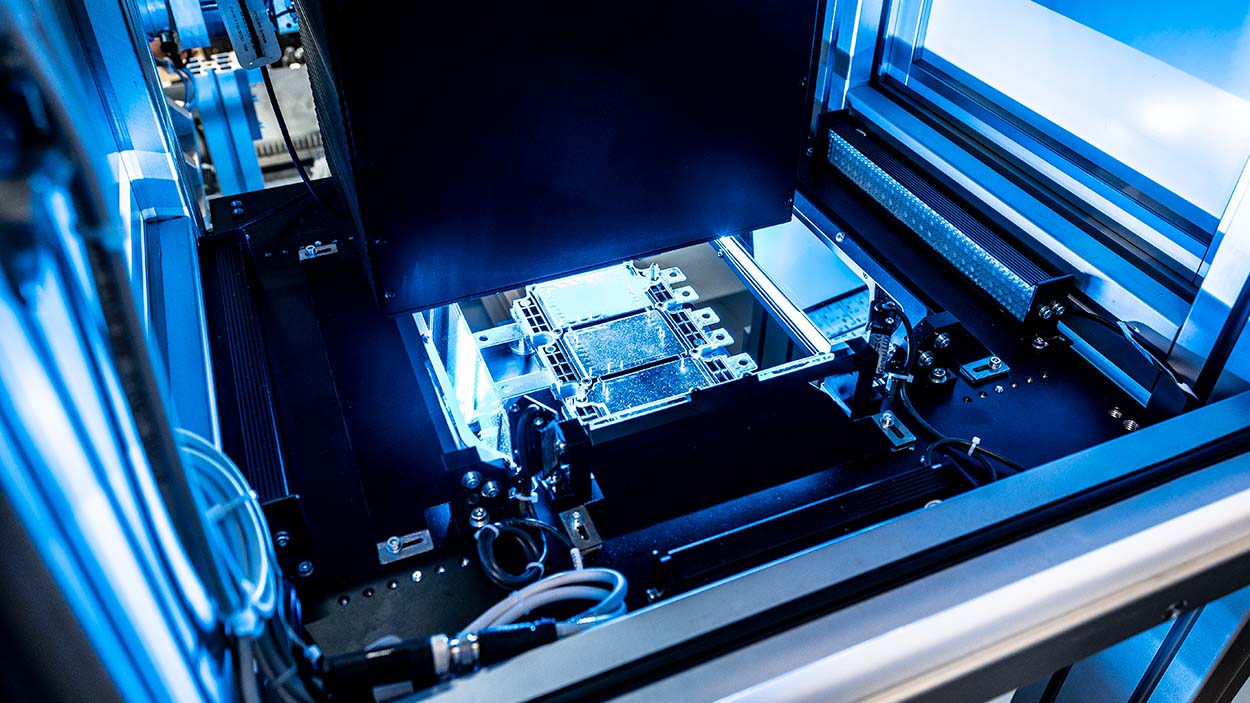

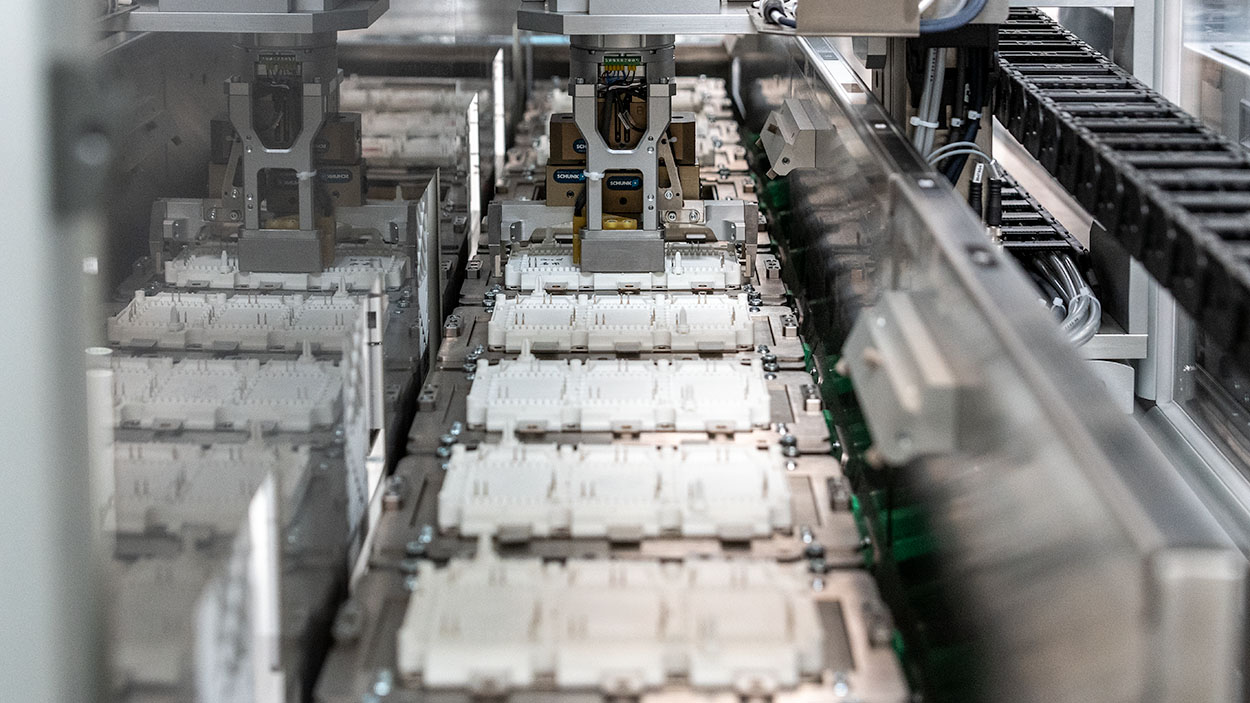

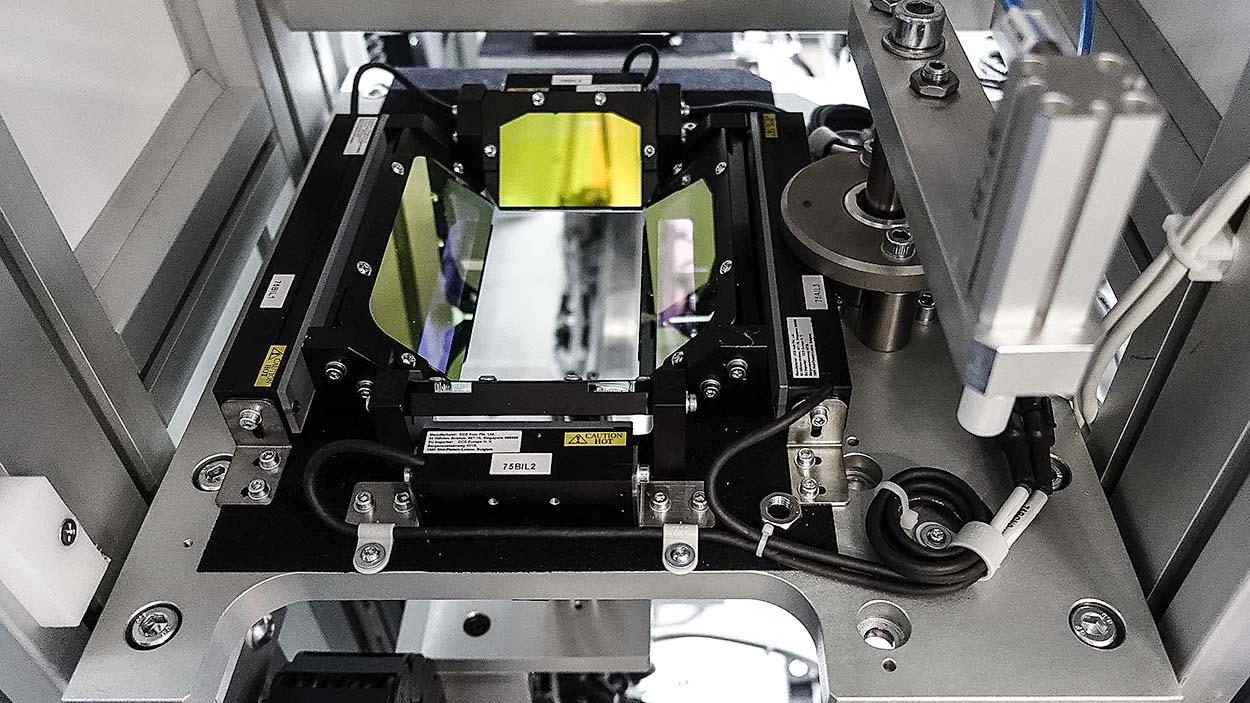

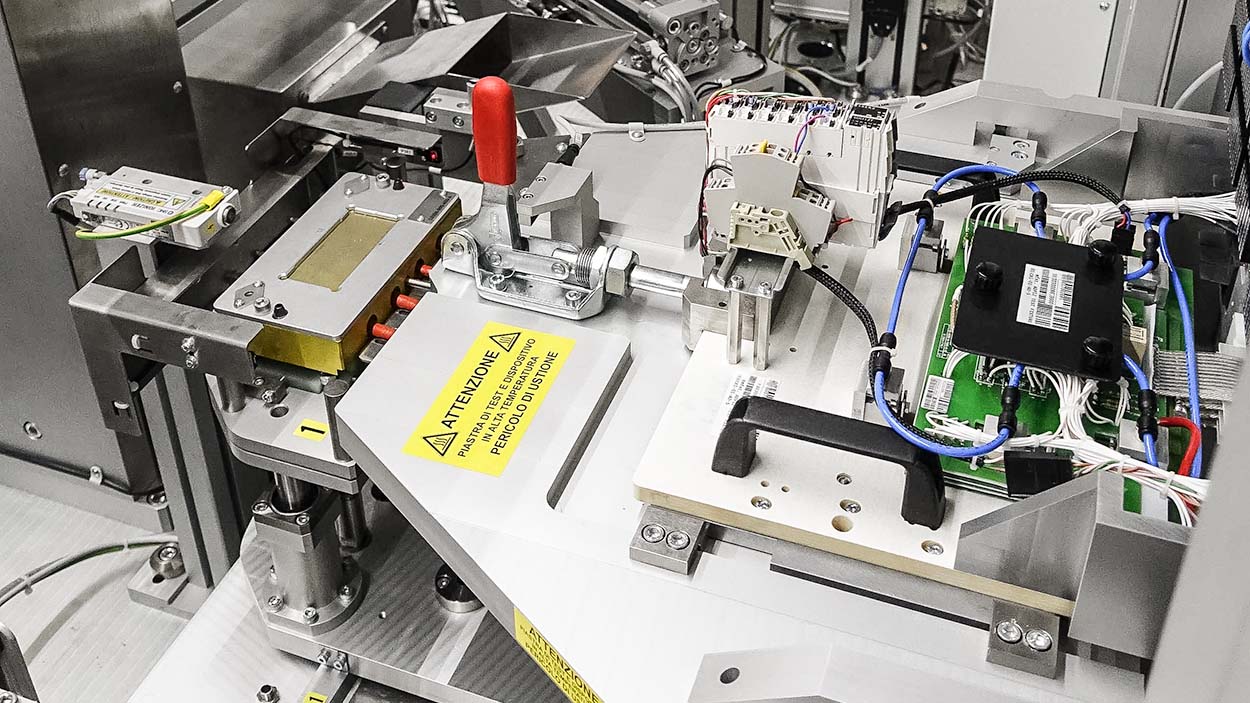

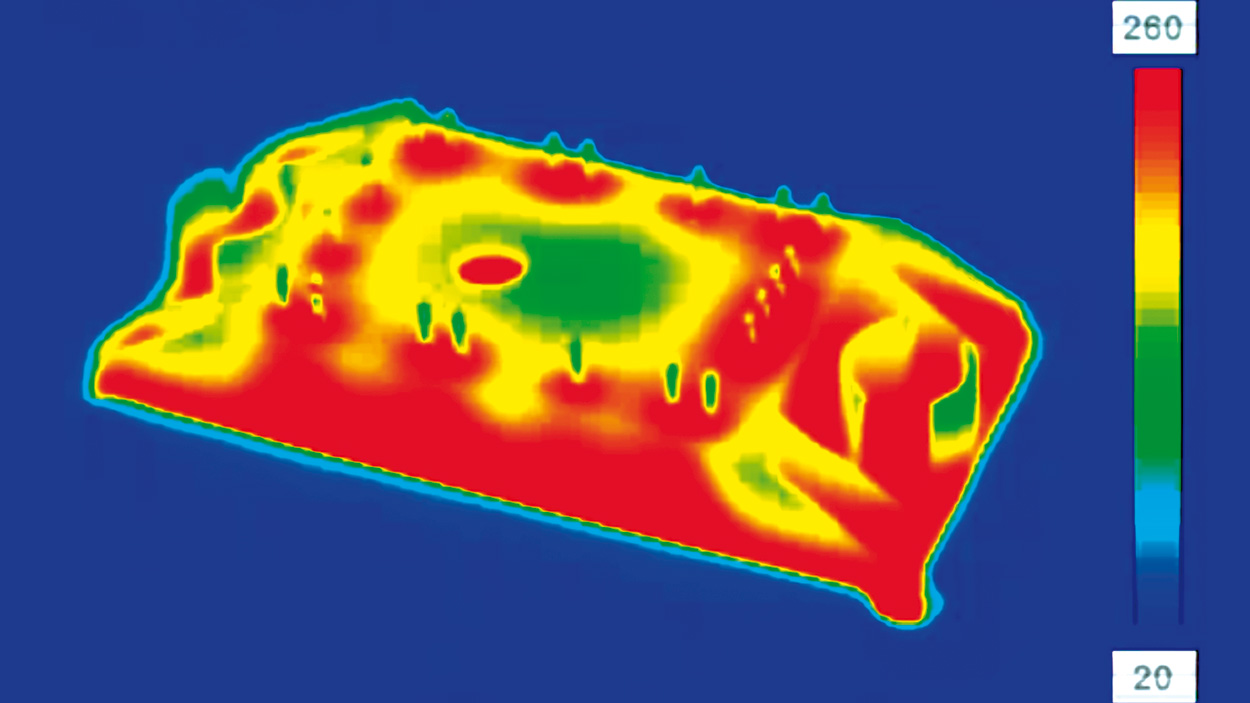

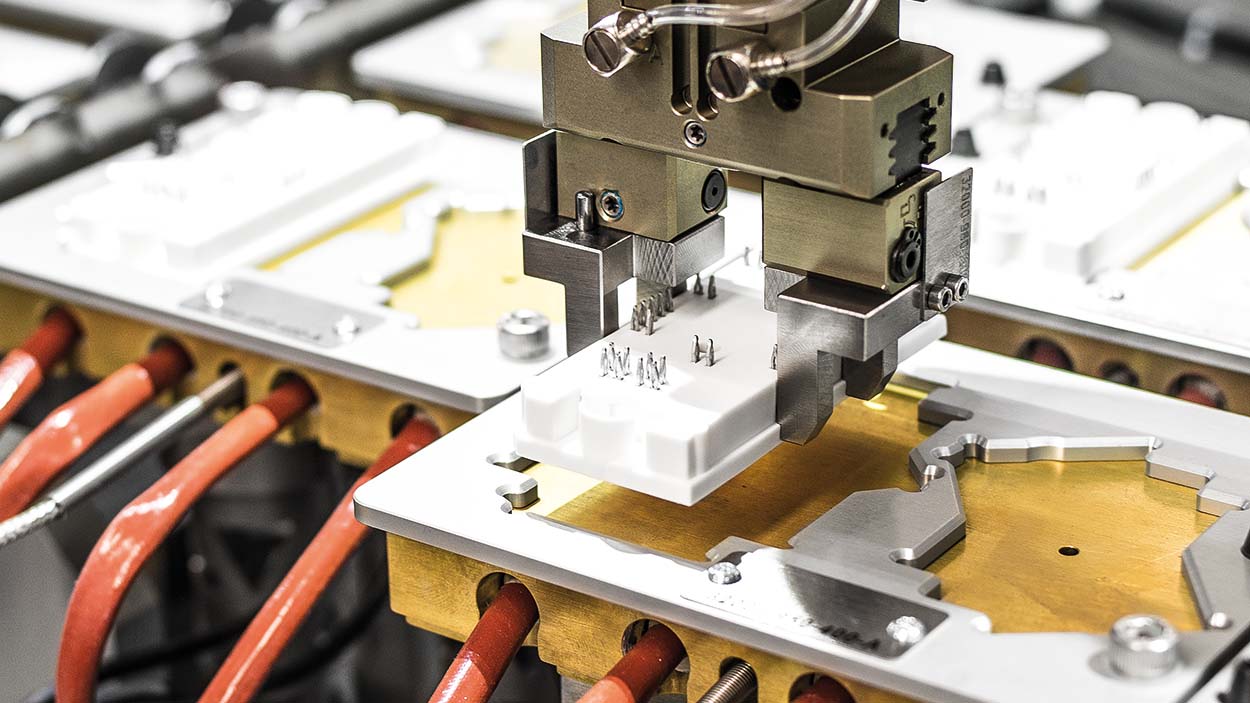

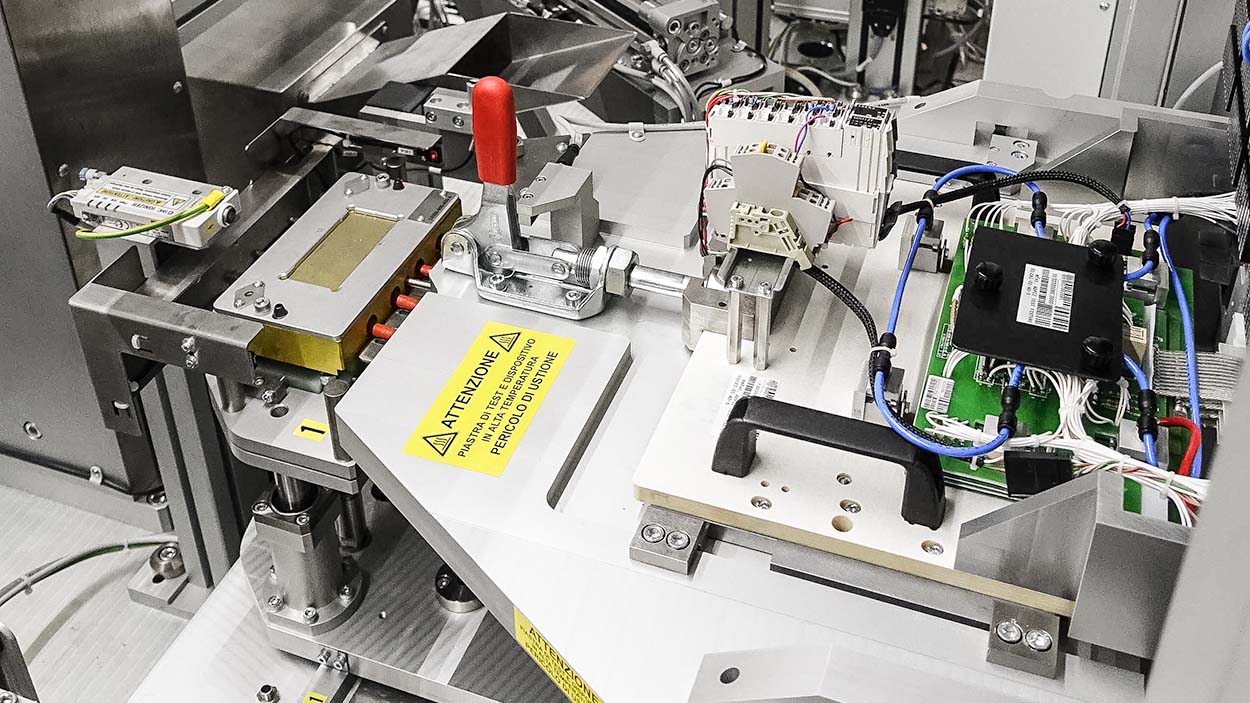

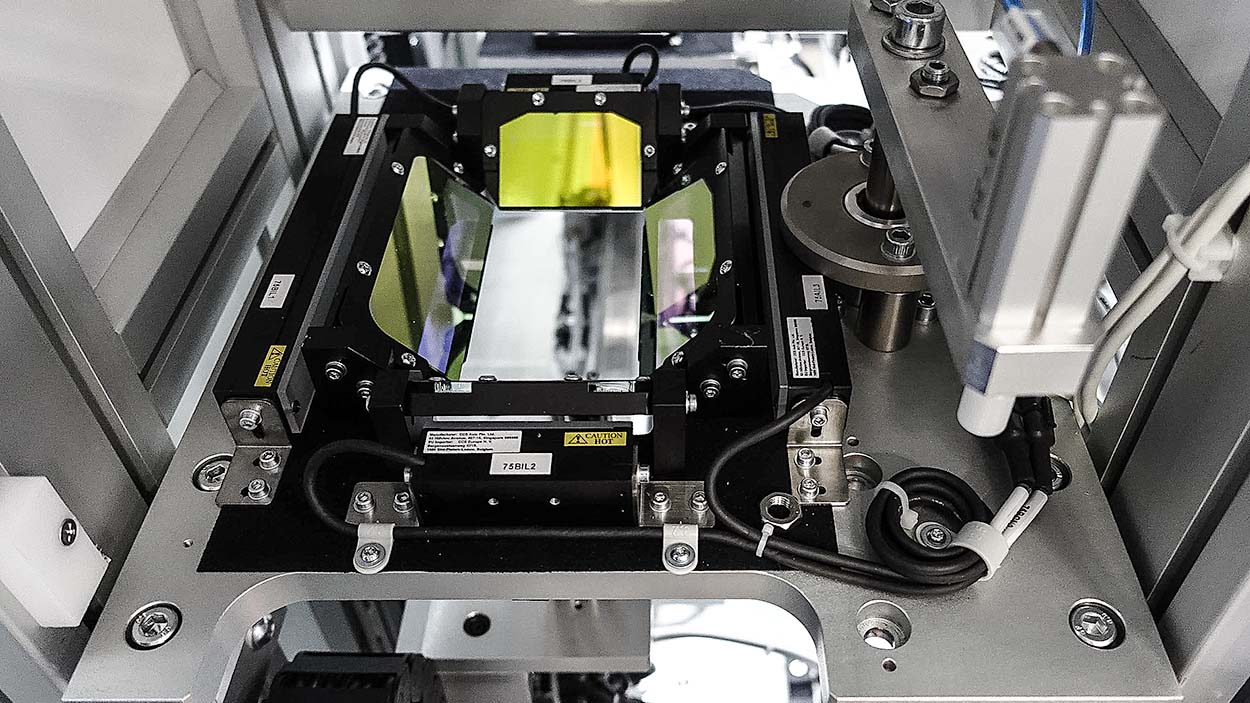

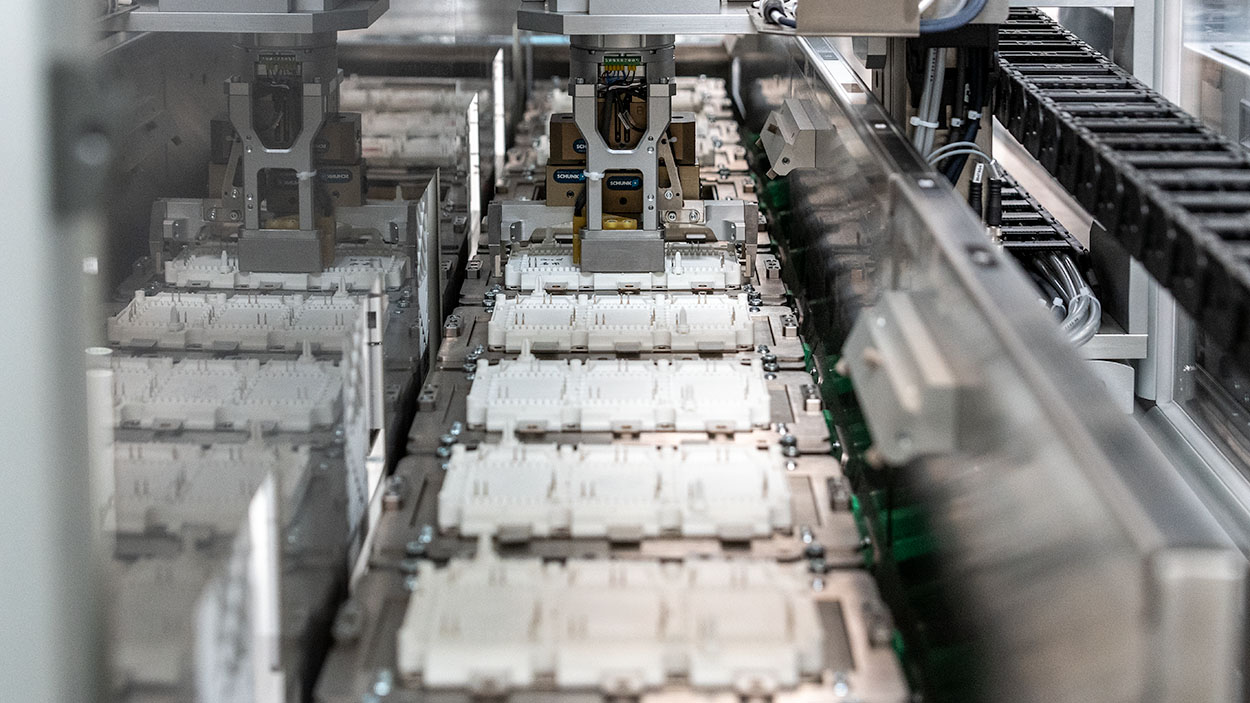

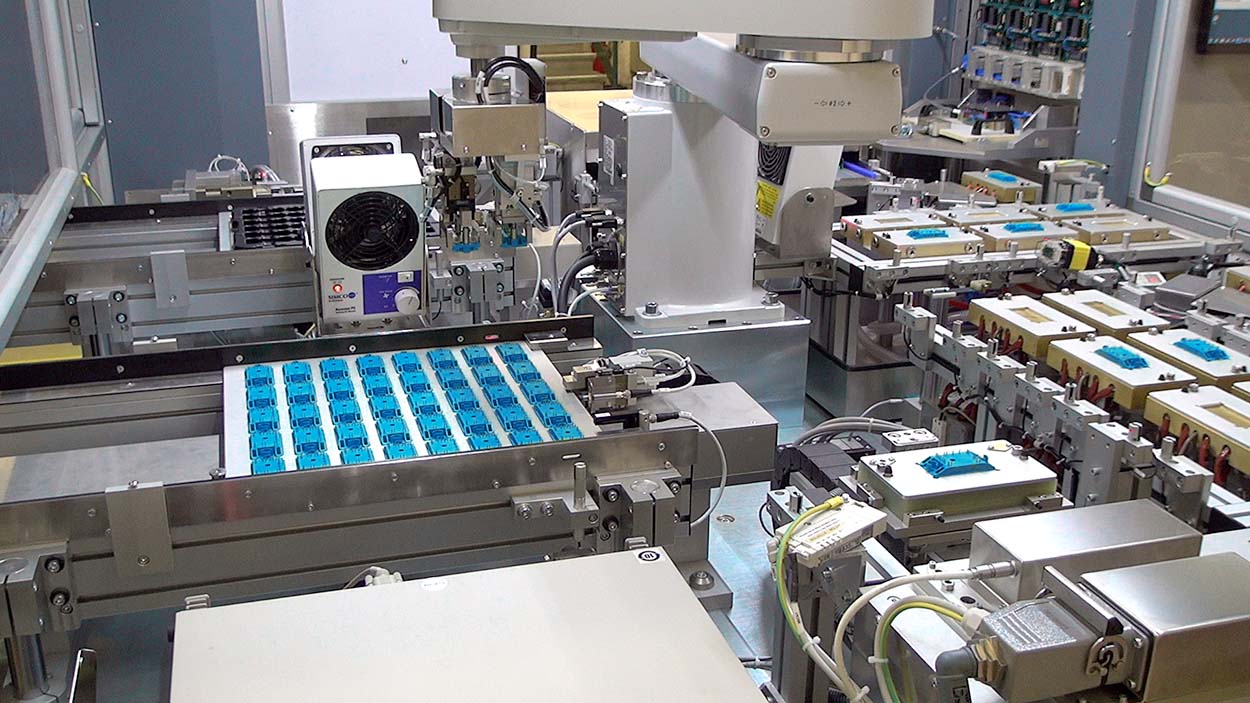

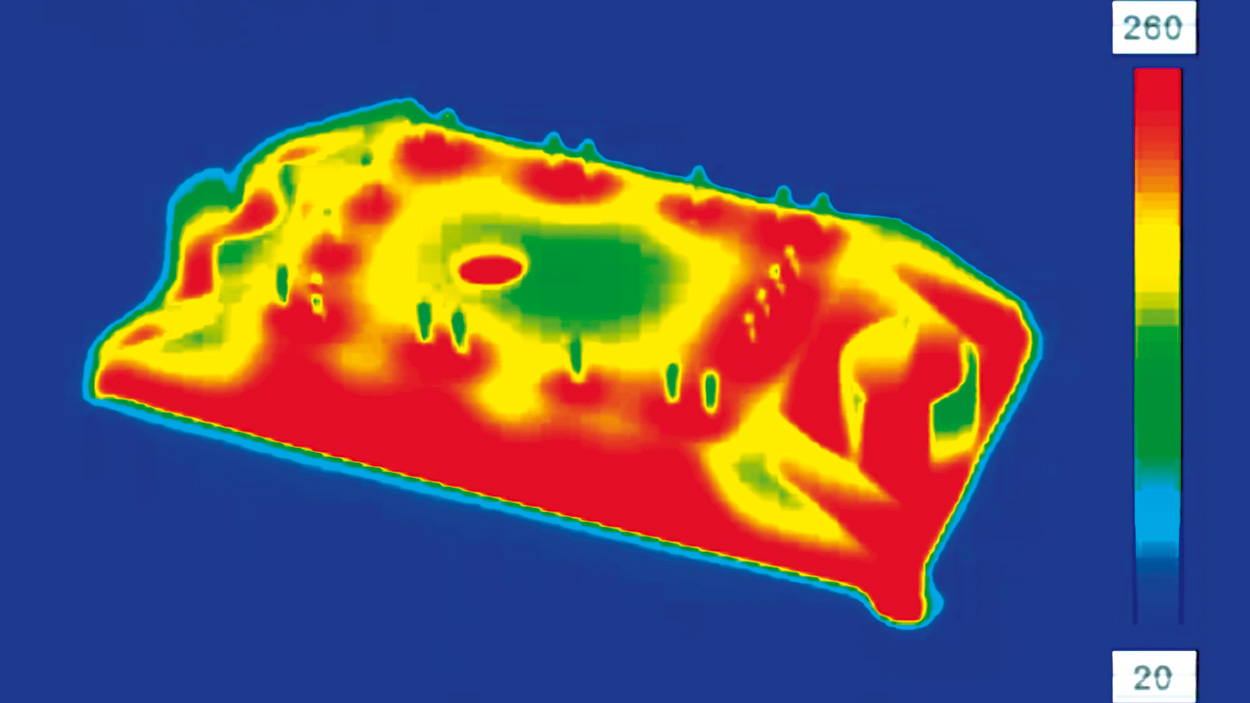

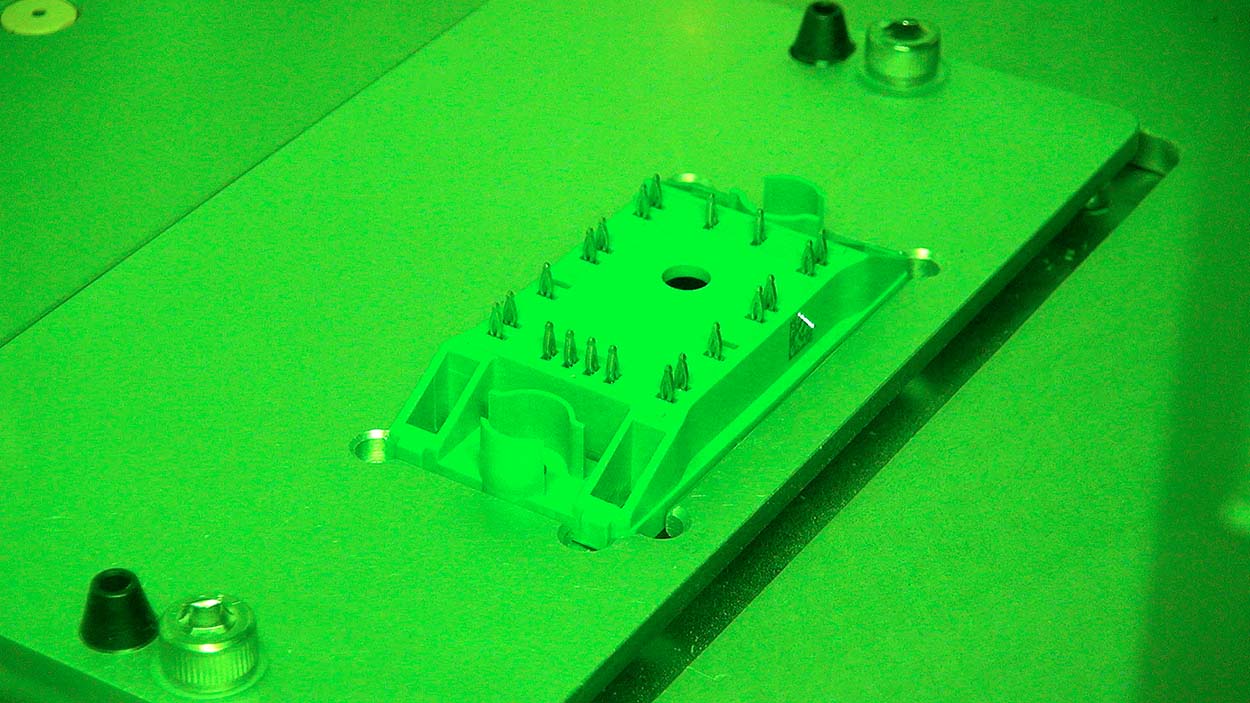

OSAI PMTH – Power Module Test Handler is a top class equipment conceived to test Power Modules.

A very high productivity, combined with an extreme reliability, makes the PMTH the perfect standard solution for the mass production. The OSAI PMTH is configurable for different packages, PIM, Econopack, HPD and many others.

The conversion time is very short, and the standard approach makes it configurable and upgradable in the field to many different test features.

Mass Production Test Handler for Power Module

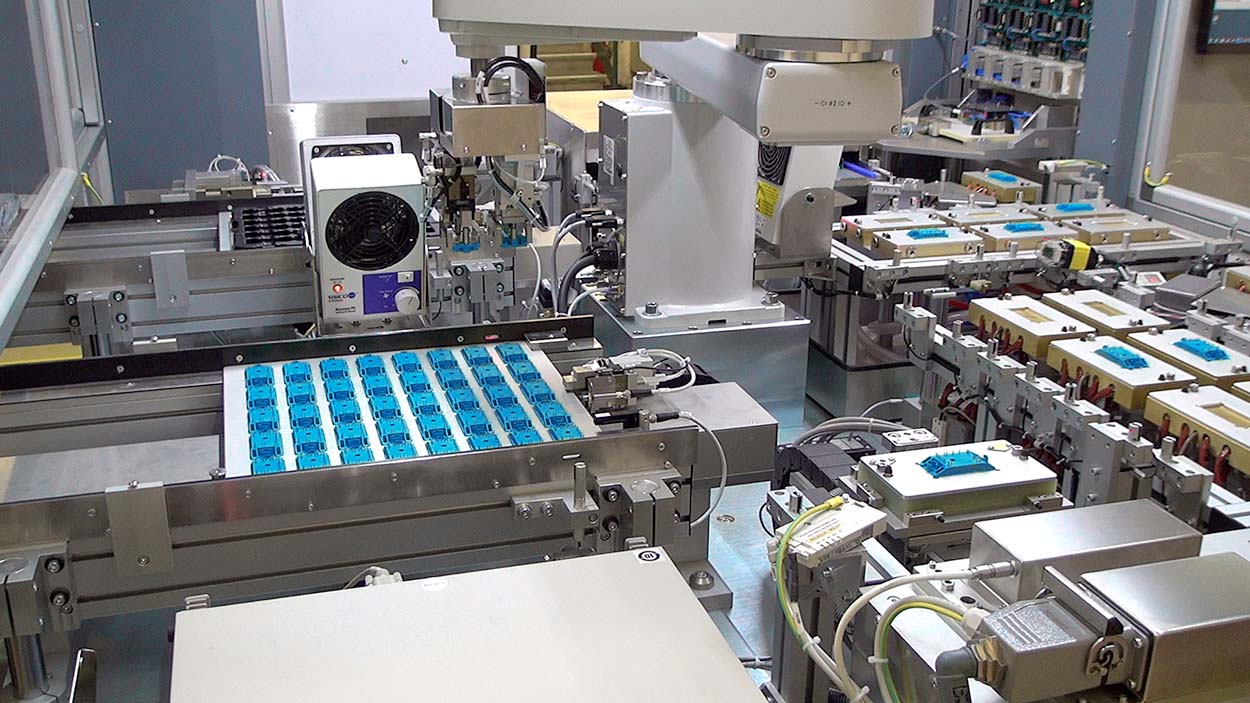

OSAI PMTH – Power Module Test Handler is a top class equipment conceived to test Power Modules.

A very high productivity, combined with an extreme reliability, makes the PMTH the perfect standard solution for the mass production. The OSAI PMTH is configurable for different packages, PIM, Econopack, HPD and many others.

The conversion time is very short, and the standard approach makes it configurable and upgradable in the field to many different test features.