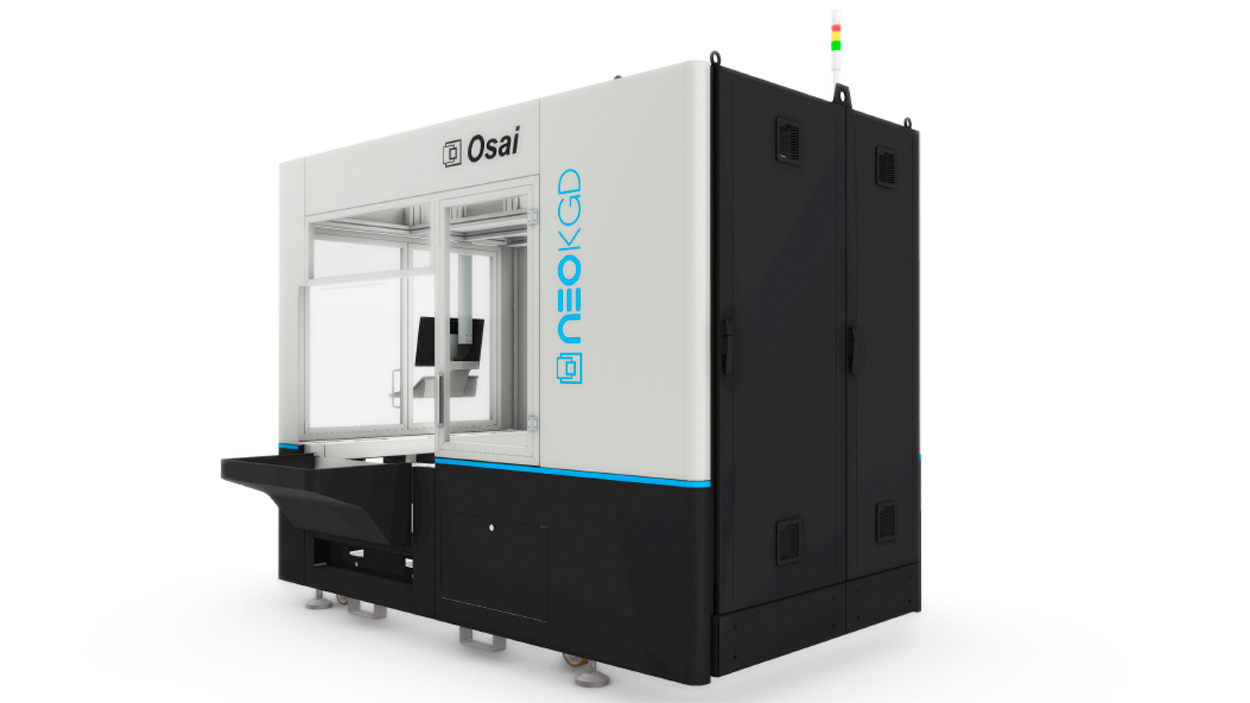

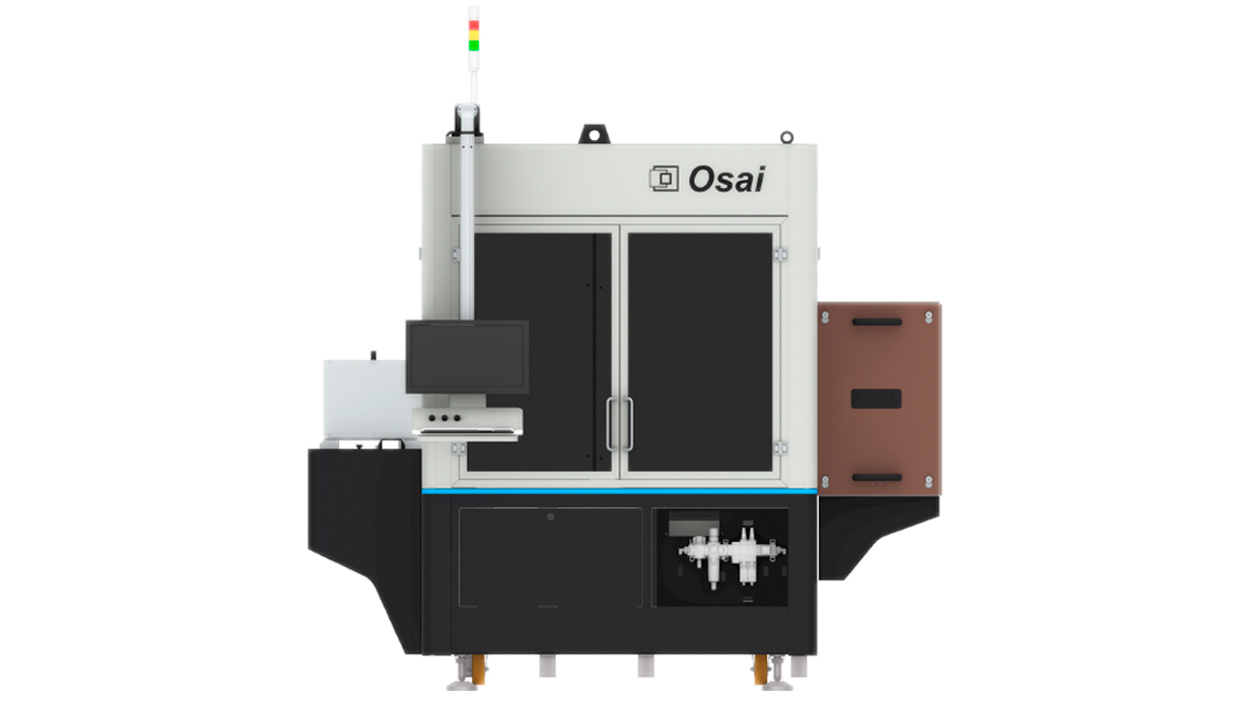

Known Good Dies Test Handler

Capable of handling and testing semiconductor devices after wafer dicing with a throughput of up to 1,800 UPH (units per hour), NeoKGD is Osai’s answer to the growing scalability needs of high-volume production in the semiconductor world. Equipped with high speed optical inspection systems, NeoKGD is able to perform the automatic handling to and from the diced wafer, its die probing and the final test at temperature (hot or ambient).

NeoKGD is a standard platform designed to accommodate the customer’s KGD handling and testing needs through a wide matrix of available options. From test requirements (environment, temperature, static and dynamic tests) to the probing technology (probecards) passing through the selection of its output and rejects segregation medias.

Multiple configurations, combined with a compact footprint and high throughput, make NeoKGD an effective test handler in reducing production costs of KGD devices and a reliable solution for the most challenging manufacturing needs.

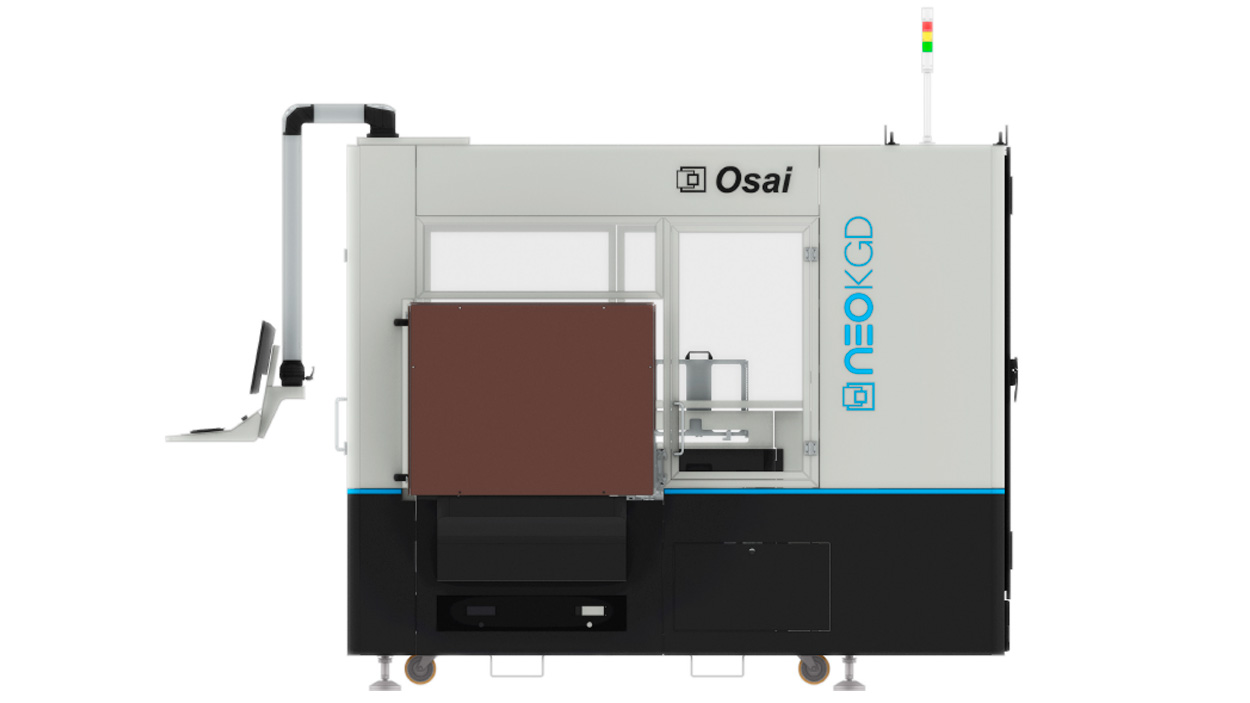

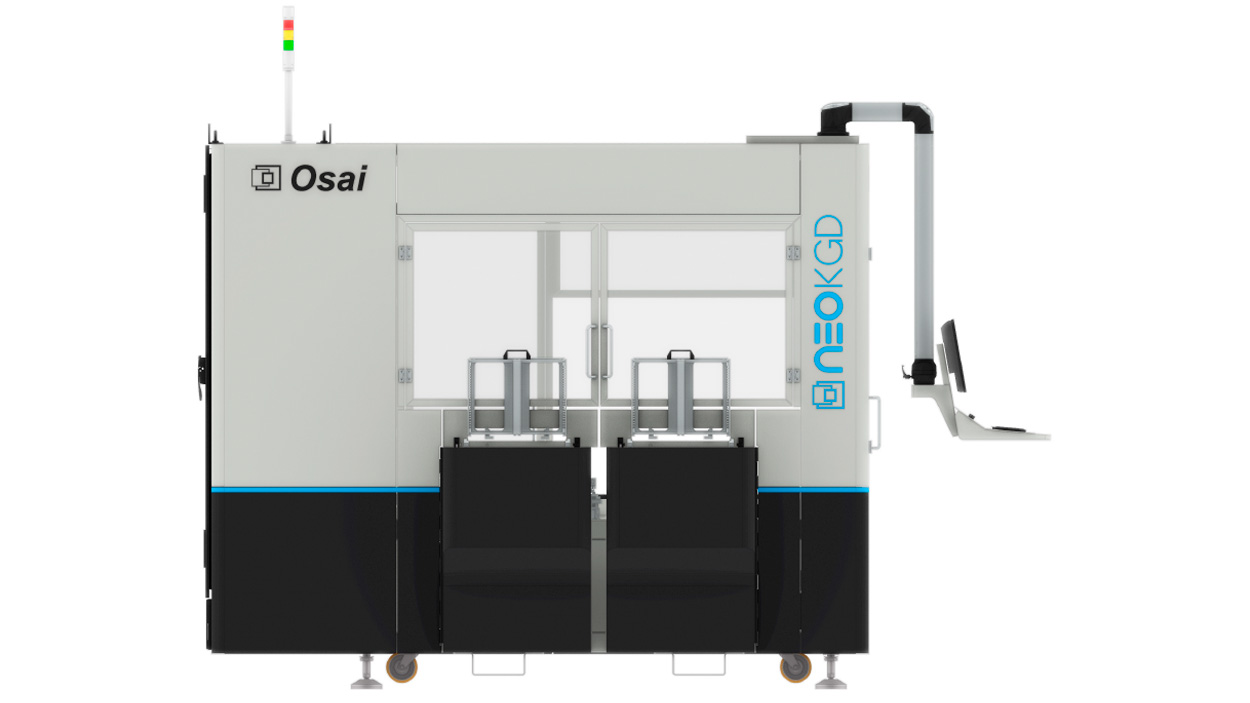

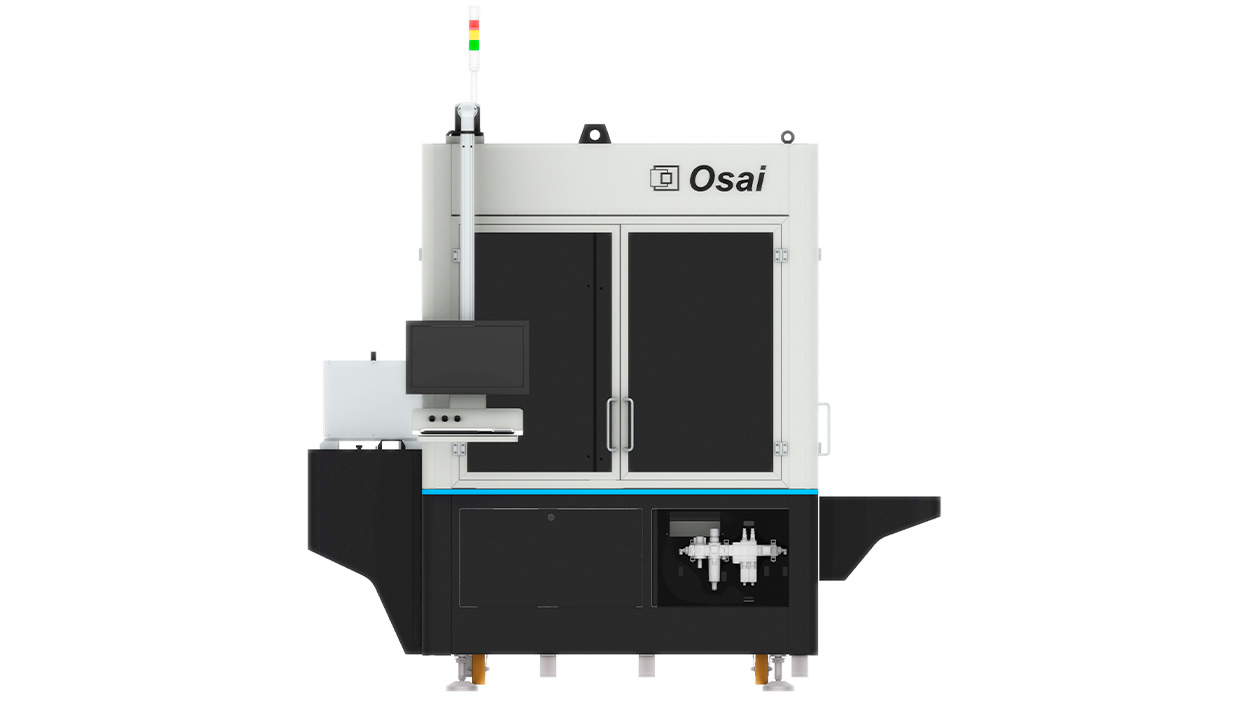

Known Good Dies Test Handler

Capable of handling and testing semiconductor devices after wafer dicing with a throughput of up to 1,800 UPH (units per hour), NeoKGD is Osai’s answer to the growing scalability needs of high-volume production in the semiconductor world. Equipped with high speed optical inspection systems, NeoKGD is able to perform the automatic handling to and from the diced wafer, its die probing and the final test at temperature (hot or ambient).

NeoKGD is a standard platform designed to accommodate the customer’s KGD handling and testing needs through a wide matrix of available options. From test requirements (environment, temperature, static and dynamic tests) to the probing technology (probecards) passing through the selection of its output and rejects segregation medias.

Multiple configurations, combined with a compact footprint and high throughput, make NeoKGD an effective test handler in reducing production costs of KGD devices and a reliable solution for the most challenging manufacturing needs.