POWER MODULES

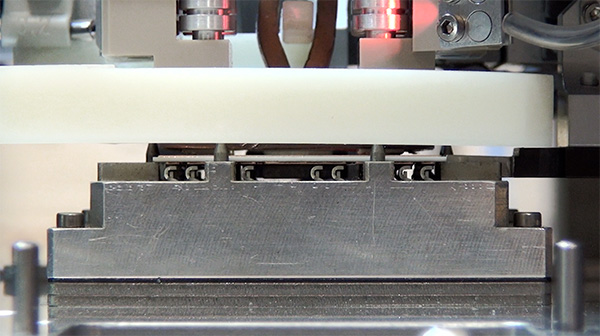

Test Handler per power module

Flessibile e Scalabile

PMTH (Power module test handler) di OSAI è l’attrezzatura di altissima qualità ideata per collaudare i moduli di potenza.

Alta produttività, combinata ad estrema affidabilità, rendono il PMTH la soluzione standard per la produzione di massa.

PMTH di OSAI è configurabile per diversi pacchetti, PIM, Econopack, HPD e molti altri.

I tempi di conversione sono molto bassi, e l’approccio standard lo rende configurabile e aggiornabile nel campo con molte caratteristiche di test.

PLAY VIDEO

DOWNLOAD DATA SHEET

PMTH’s Keypoints

PRINCIPALI FUNZIONALITÀ

PMTH

PRINCIPALI CARATTERISTICHE

La serie di celle di test per power module di OSAI fornisce una soluzione innovativa scalabile e configurabile per il test del power module:

- Test alta temperatura

- Test temperatura ambiente

- Test di capacità AC/DC

- Test di capacità ISO

- Supporto input/output vassoio e blister

- Alimentazione cestino scarti su tubi o nastro

- Separazione configurabile

- Controllo contatti

- Marcatura a laser

- Ispezione ottica

- Controllo peso

- Stazione di inversione

NEOHANDLER

Testing per Produzione di Massa

NeoHandler per componenti discreti è la soluzione migliore per il collaudo di IGBT, Mosfet e altri dispositivi di potenza.

I pacchetti più comuni sono utilizzati e compatibili con NeoHandler, come TO247, TO220, D2Pack.

La perfetta integrazione con ATE specifico ad alta potenza rende NeoHandler la soluzione perfetta per ridurre l’induttanza di deformazione e ottenere il meglio dalle prestazioni ATE.

Punti Chiave

NEOHANDLER

PRINCIPALI CARATTERISTICHE

- Pass di output dei dispositivi(autonomia fino a 20 tubi)

- Nr. 5 cestini programmabili per dispositivi NOK nella cassa

- Caricamento nuovi dispositivi alimentati nel tubo (autonomia da nr. 20 tubi)

- Pick up multiplo con multi-siti scalabili secondo i tempi di test

- Integrazione tester e presa scheda

POWER DEVICES PACKAGING

Facile Produzione di Massa

In qualità di azienda di automazione, OSAI può offrire molte soluzioni per l’assemblaggio automatico di power module.

Dalle semplici schede master al test finale, l’esperienza OSAI nell’automazione dell’applicazione dei semiconduttori è in grado di rendere facile la produzione di massa e priva di errori umani al 100%.

Punti chiave

PACCHETTI POWER DEVICES

PRINCIPALI CARATTERISTICHE

- Rigatura a Laser per substrato in ceramica

- Marcatura a Laser

per substrato in ceramica - Macchine di spezzatura

per substrato in ceramica - Saldatura pin ad induzione (brevettato) o inserimento automatico pin

- Assemblaggio, incollatura, avvitamento e polimerizzazione UV contenitore in plastica

- Incapsulamento a vuoto gel silicone

POWER MODULES

Flexible and Scalable

Test Handler for power module

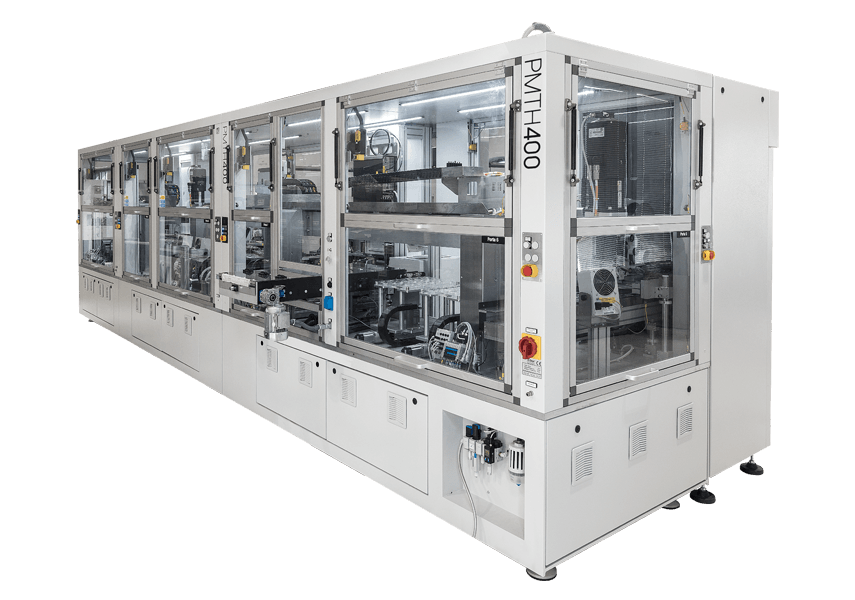

The Osai PMTH ( Power module test handler ) is a top class equipment conceived to test Power Modules. A very high productivity, combined with an extreme reliability, makes the PMTH the perfect standard solution for the mass production.

The Osai PMTH is configurable for different packages, PIM, Econopack, HPD and many others. The conversion time is very low, and the standard approach makes it configurable and upgradable on field to many different test features.

PLAY VIDEO

DOWNLOAD DATA SHEET

PMTH’s Keypoints

MAIN FEATURES

PMTH

MAIN CHARACTERISTICS

The OSAI Power module test cell series, provides a breakthrough scalable and configurable solution for Power Module test:

- Hot temperature test

- Ambient temperature test

- AC/DC Test capability

- ISO Test capability

- Tray and Blister input/output media

- Reject bin feed on tubes or tape

- Configurable sorting

- Leads check

- Laser marking

- Optical inspection

- Weight check

- Flip station

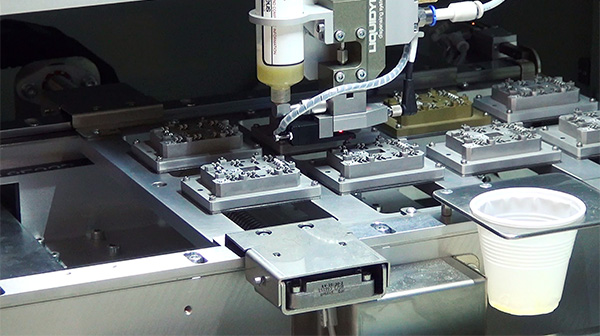

NEOHANDLER

Mass Production Testing

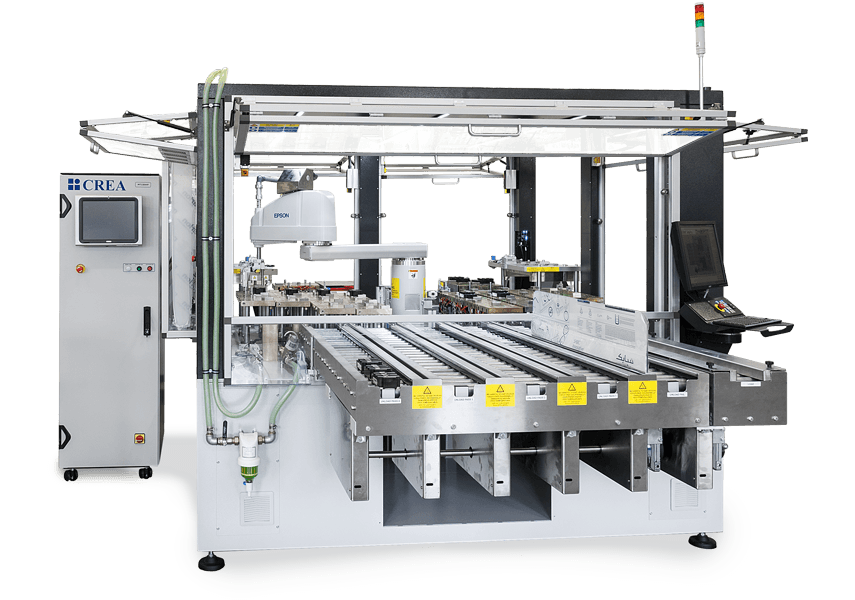

The NeoHandler for discrete components is the best solution for the test of IGBTs, Mosfet and other power devices. The most common packages are used and compatible with the NeoHandler, like TO247, TO220, D2Pack. The perfect integration with specific hi-power ATE makes the NeoHandler the perfect solution to reduce the strain inductance and make the most of the ATE performances.

Keypoints

NEOHANDLER

MAIN CHARACTERISTICS

- Pass devices output Tube (N° 20 tubes autonomy)

- N° 5 programmable bins for NOK devices in box

- Loading Fresh devices feeded in Tube (N° 20 tubes autonomy)

- Multi Pick-Up developed with scalable multisite according to the test time

- Tester and socketboard integration

POWER DEVICES PACKAGING

Easy Mass Production

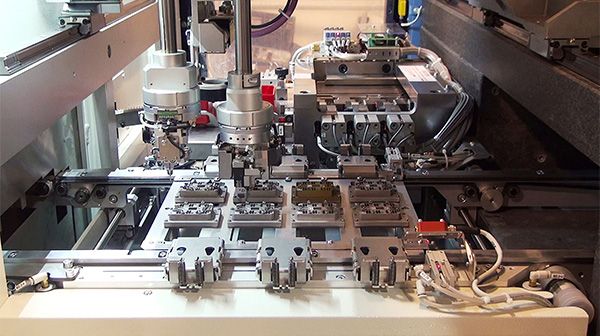

Being an automation company, Osai can offer many solutions for the automatic assembly of power modules. From the bare mastercard to the final test, the Osai experience in semiconductor application automation can make the mass production easy, reliable and 100% human error free.

Keypoints

POWER DEVICES PACKAGING

MAIN CHARACTERISTICS

- Laser scribing for ceramic substrate

- Laser marking for ceramic substrate

- Breaking machines for ceramic substrate

- Induction pin soldering ( patented ) or automatic pin insertion

- Plastic case assembly, gluing, screwing and UV curing

- Sil gel vacuum potting

POWER MODULES

Flexibel und skalierbar

Testhandler für Leistungsmodule

OSAI PMTH (Power Module Test Handler) ist ein erstklassiges Gerät, das zum Testen von Power Modulen entwickelt wurde. Eine sehr hohe Produktivität, kombiniert mit einer extremen Zuverlässigkeit, macht den PMTH die perfekten Standardlösung für die Massenproduktion.

Das OSAI PMTH ist für verschiedene Pakete, PIM, Econopack, HPD und viele andere konfigurierbar.

Die Konvertierungszeit ist sehr kurz, und der Standardansatz macht sie im Feld konfigurierbar und auf viele verschiedene Testfunktionen erweiterbar..

VIDEO ABSPIELEN

DATENBLATT HERUNTERLADEN

PMTH’s Keypoints

HAUPTEIGENSCHAFTEN

PMTH

HAUPTEIGENSCHAFTEN

Die Testzellenreihe für OSAI Power Module

bietet eine bahnbrechende skalierbare und konfigurierbare Lösung zum Testen von Power Modulen:

- Heißtemperaturprüfung

- Umgebungstemperaturprüfung

- AC/DC Testfähigkeit

- ISO Testfähigkeit

- Tablett- und Blister Ein- und Ausgabemedien

- Behälterzuführung auf Röhren oder Band abweisen

- Konfigurierbare Sortierung

- Führungsprüfung

- Lasermarkierung

- Optische Inspektion

- Gewichtskontrolle

- Flip station

NEOHANDLER

Massenproduktionsprüfung

Der NeoHandler für diskrete Komponenten ist die beste Lösung für den Test von IGBTs, Mosfet und andere Power Devices. Es werden die gängigsten Pakete, wie TO247, TO220, D2Pack verwendet, die mit dem NeoHandler kompatibel sind. Die perfekte Integration mit spezifischem Hochleistungs-ATE macht den NeoHandler die perfekte Lösung, um die Dehnungsinduktivität zu reduzieren und die ATE-Leistungen optimal zu nutzen.

Schwerpunkte

NEOHANDLER

HAUPTEIGENSCHAFTEN:

- Ausgabeleistung der Geräte

(bis zu 20 Röhren Autonomie) - 5 programmierbare Behälter

für NOK-Geräte in der Box - Laden von neuen Geräten, die in die Röhre eingespeist werden (bis zu 20 Röhren)

- Mehrfachabholung

mit skalierbaren Multisites entsprechend der Testzeit - Integration von Tester und Steckplatine

POWER DEVICES PACKAGING

Einfache Massenproduktion

Als Automatisierungsunternehmen kann Osai viele Lösungen für die automatische Montage von Leistungsmodulen anbieten. Von der bloßen Masterkarte bis zum Endtest kann die OSAI-Erfahrung in der Automatisierung von Halbleiteranwendungen die Massenproduktion einfach, zuverlässig und 100% fehlerfrei machen.

Schwerpunkte:

POWER DEVICES PACKAGING

HAUPTEIGENSCHAFTEN:

- Laserritzen

für Keramiksubstrate - Lasermarkierung

für Keramiksubstrate - Brechmaschinen

für Keramiksubstrat - Induktionsstiftlöten (patentiert) oder automatische Stifteingabe

- Kunststoffgehäusemontage, Kleben, Schrauben und UV-Härten

- Sil Gel Vakuumverguss

POWER MODULES

Flexible and Scalable

Test Handler for power module

The Osai PMTH ( Power module test handler ) is a top class equipment conceived to test Power Modules. A very high productivity, combined with an extreme reliability, makes the PMTH the perfect standard solution for the mass production.

The Osai PMTH is configurable for different packages, PIM, Econopack, HPD and many others. The conversion time is very low, and the standard approach makes it configurable and upgradable on field to many different test features.

PLAY VIDEO

DOWNLOAD DATA SHEET

PMTH’s Keypoints

MAIN FEATURES

PMTH

MAIN CHARACTERISTICS

The OSAI Power module test cell series, provides a breakthrough scalable and configurable solution for Power Module test:

- Hot temperature test

- Ambient temperature test

- AC/DC Test capability

- ISO Test capability

- Tray and Blister input/output media

- Reject bin feed on tubes or tape

- Configurable sorting

- Leads check

- Laser marking

- Optical inspection

- Weight check

- Flip station

NEOHANDLER

Mass Production Testing

The NeoHandler for discrete components is the best solution for the test of IGBTs, Mosfet and other power devices. The most common packages are used and compatible with the NeoHandler, like TO247, TO220, D2Pack. The perfect integration with specific hi-power ATE makes the NeoHandler the perfect solution to reduce the strain inductance and make the most of the ATE performances.

Keypoints

NEOHANDLER

MAIN CHARACTERISTICS

- Pass devices output Tube (N° 20 tubes autonomy)

- N° 5 programmable bins for NOK devices in box

- Loading Fresh devices feeded in Tube (N° 20 tubes autonomy)

- Multi Pick-Up developed with scalable multisite according to the test time

- Tester and socketboard integration

POWER DEVICES PACKAGING

Easy Mass Production

Being an automation company, Osai can offer many solutions for the automatic assembly of power modules. From the bare mastercard to the final test, the Osai experience in semiconductor application automation can make the mass production easy, reliable and 100% human error free.

Keypoints

POWER DEVICES PACKAGING

MAIN CHARACTERISTICS

- Laser scribing for ceramic substrate

- Laser marking for ceramic substrate

- Breaking machines for ceramic substrate

- Induction pin soldering ( patented ) or automatic pin insertion

- Plastic case assembly, gluing, screwing and UV curing

- Sil gel vacuum potting