Compact system, fast cycle time

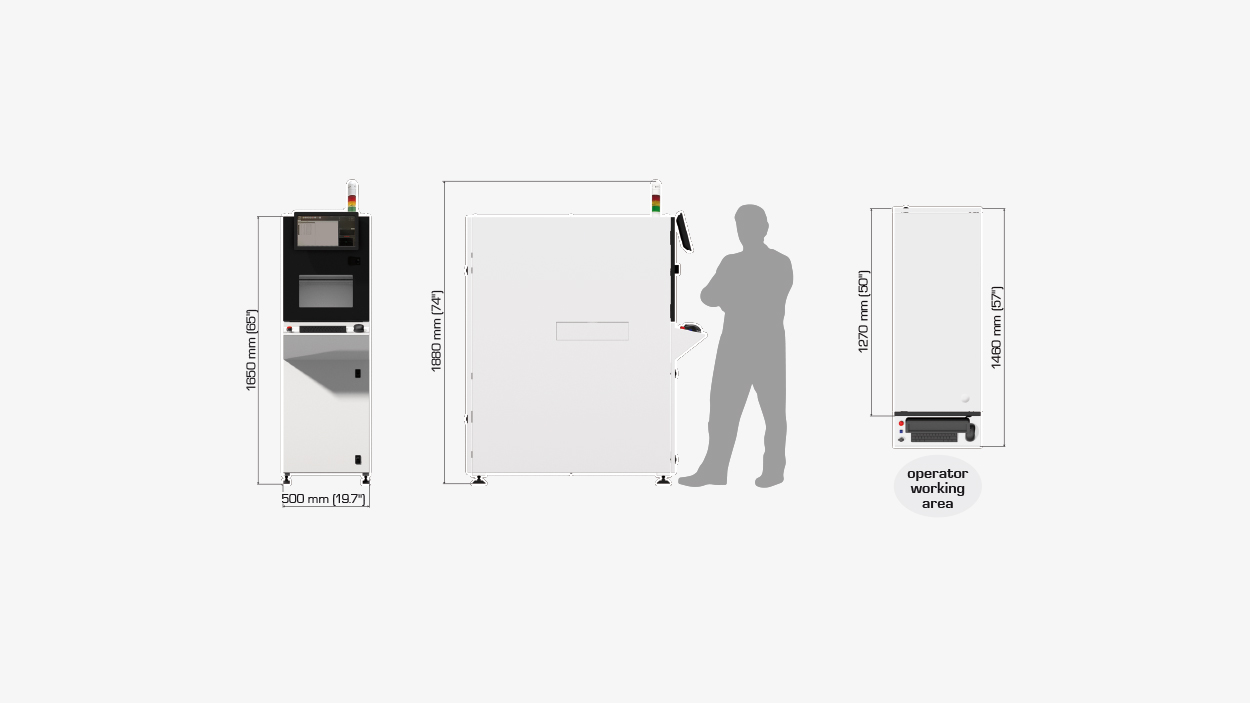

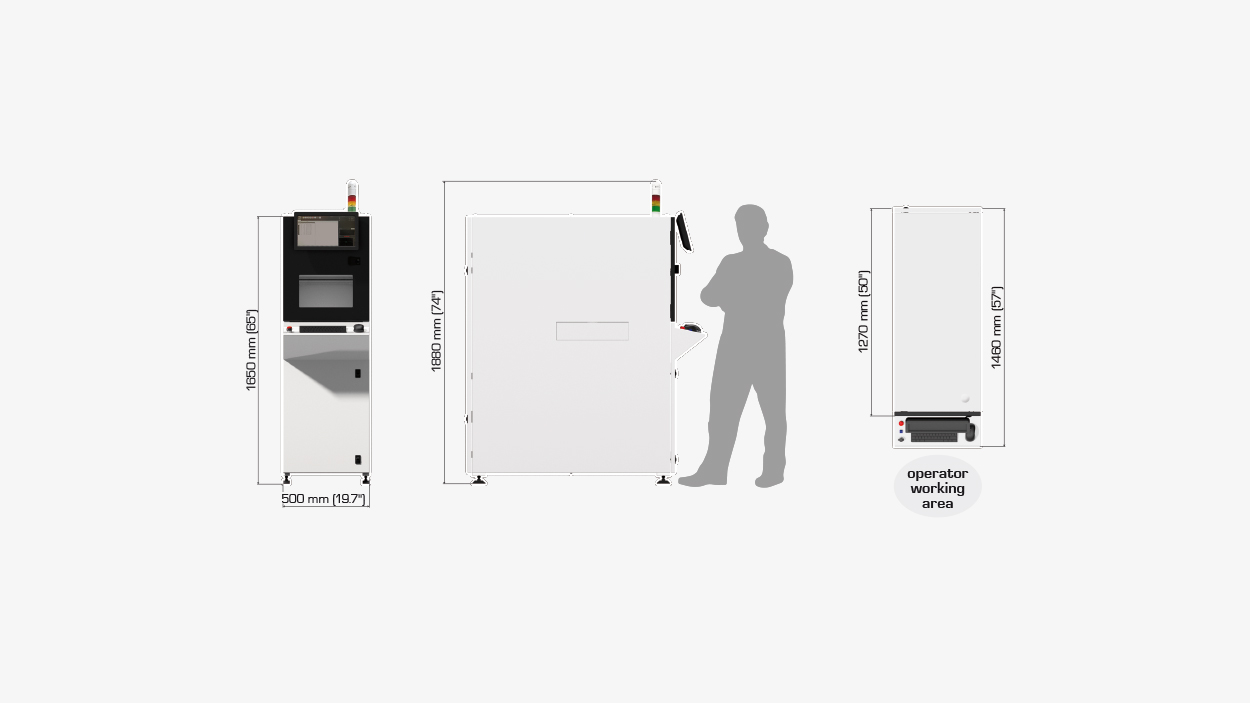

NeoMark Easy is the solution for those looking for a compact, versatile and fast marking system. The galvo head has a fixed position and covers the entire working area, with no need for external axes to move neither the board below the Laser nor the Laser above the board.

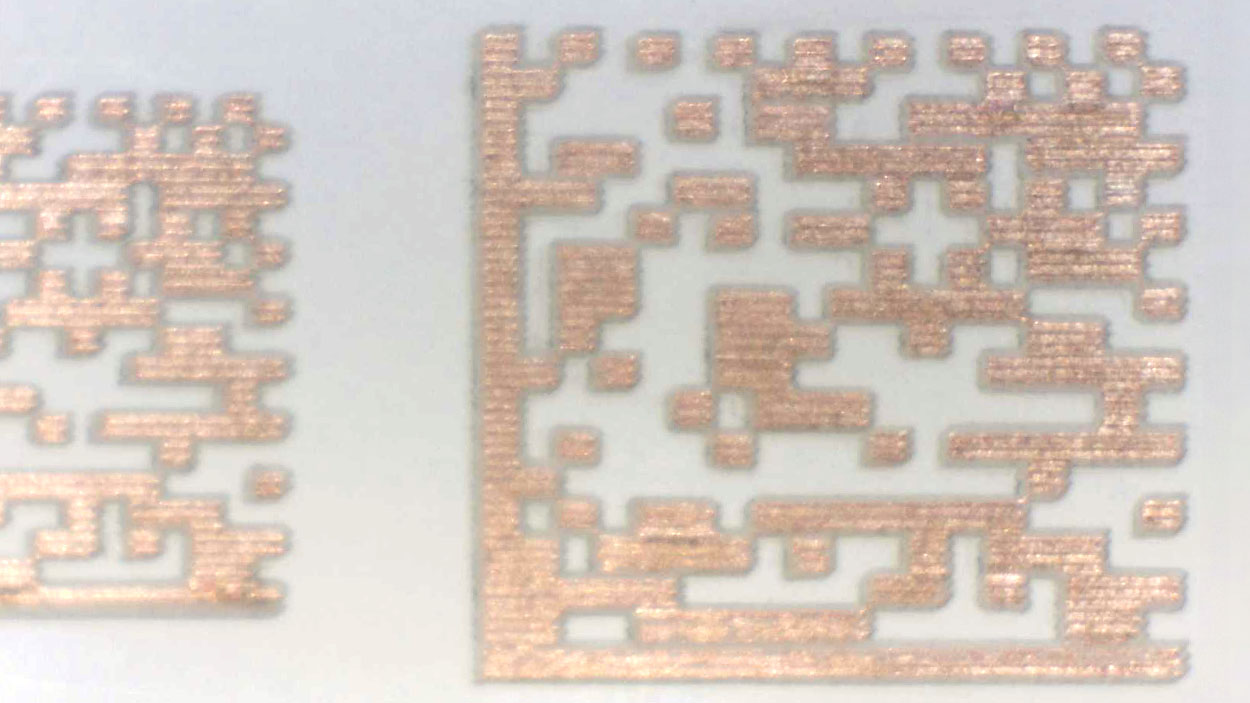

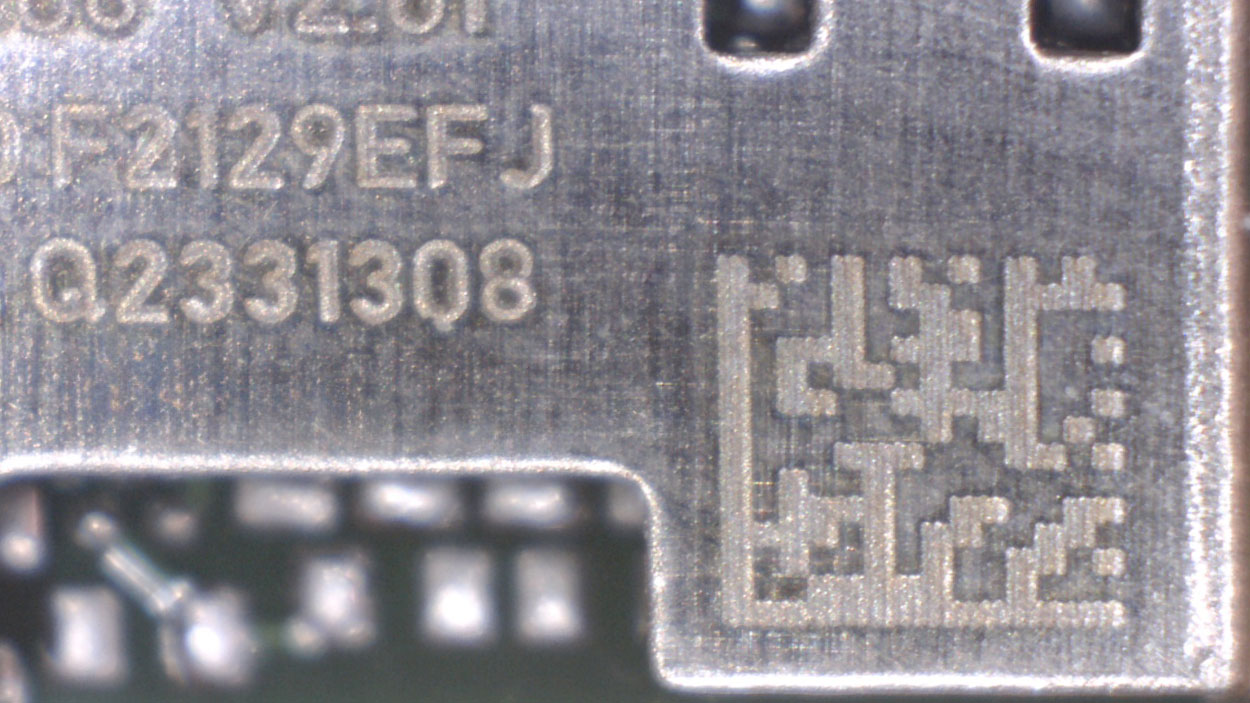

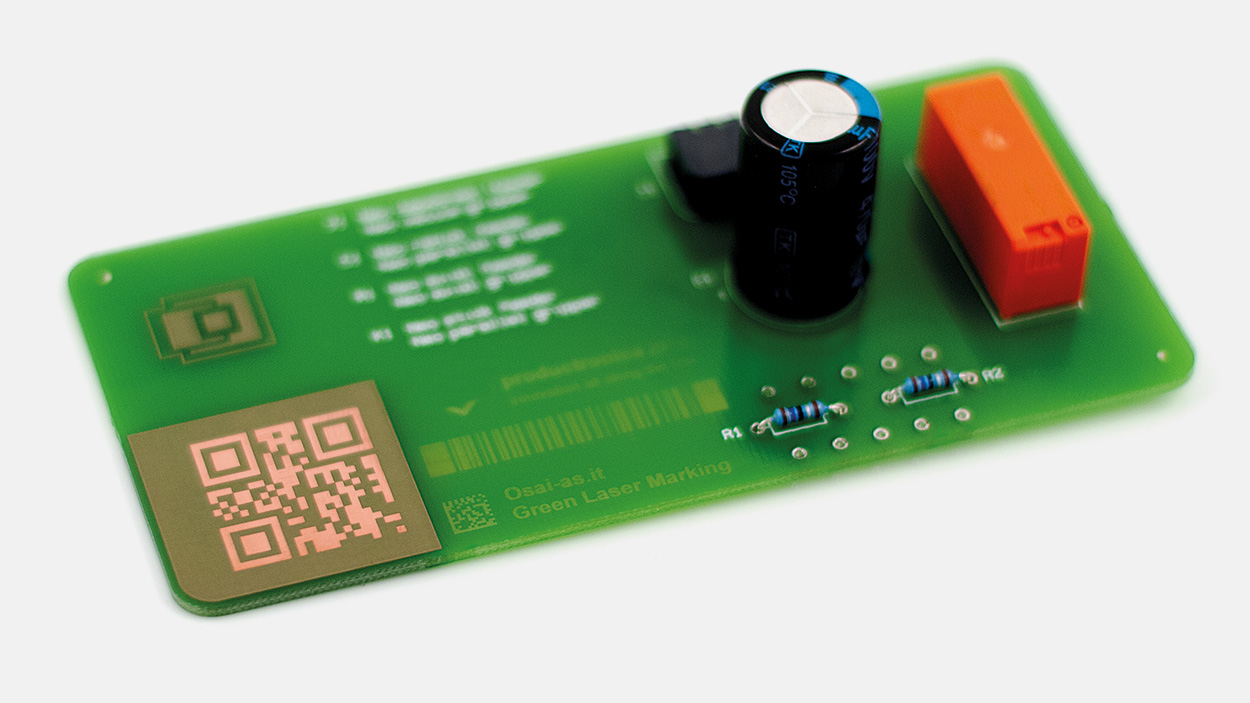

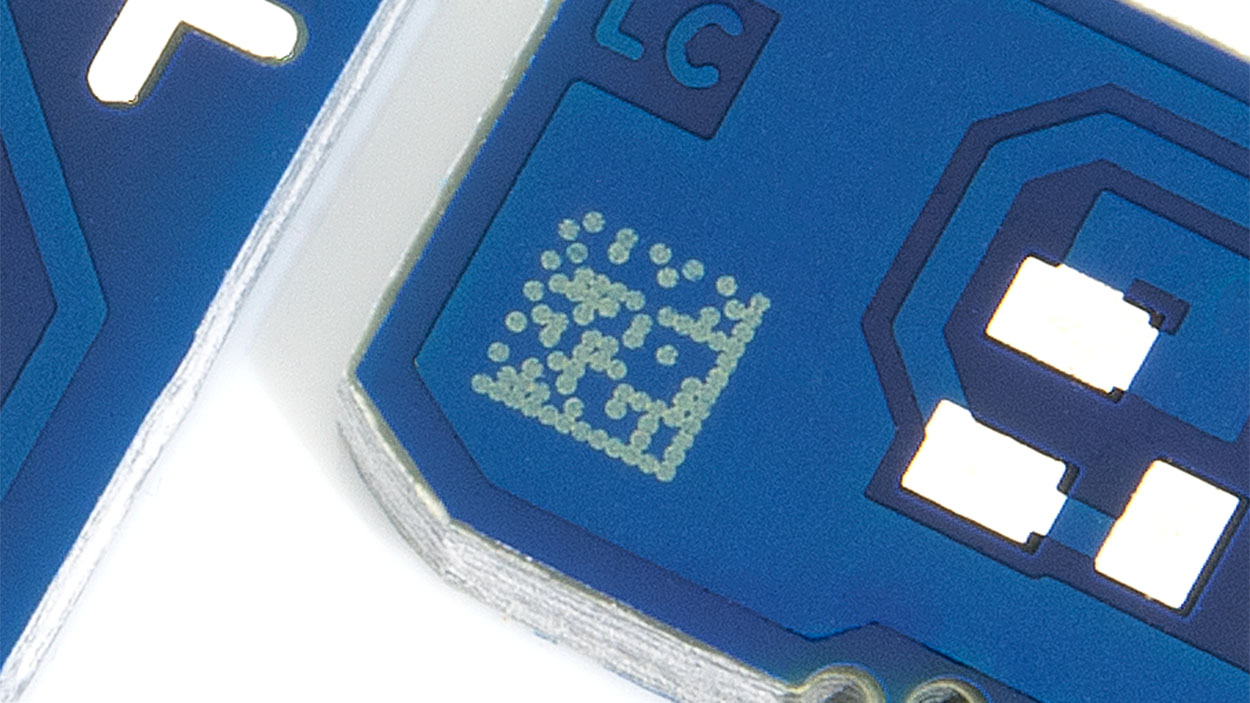

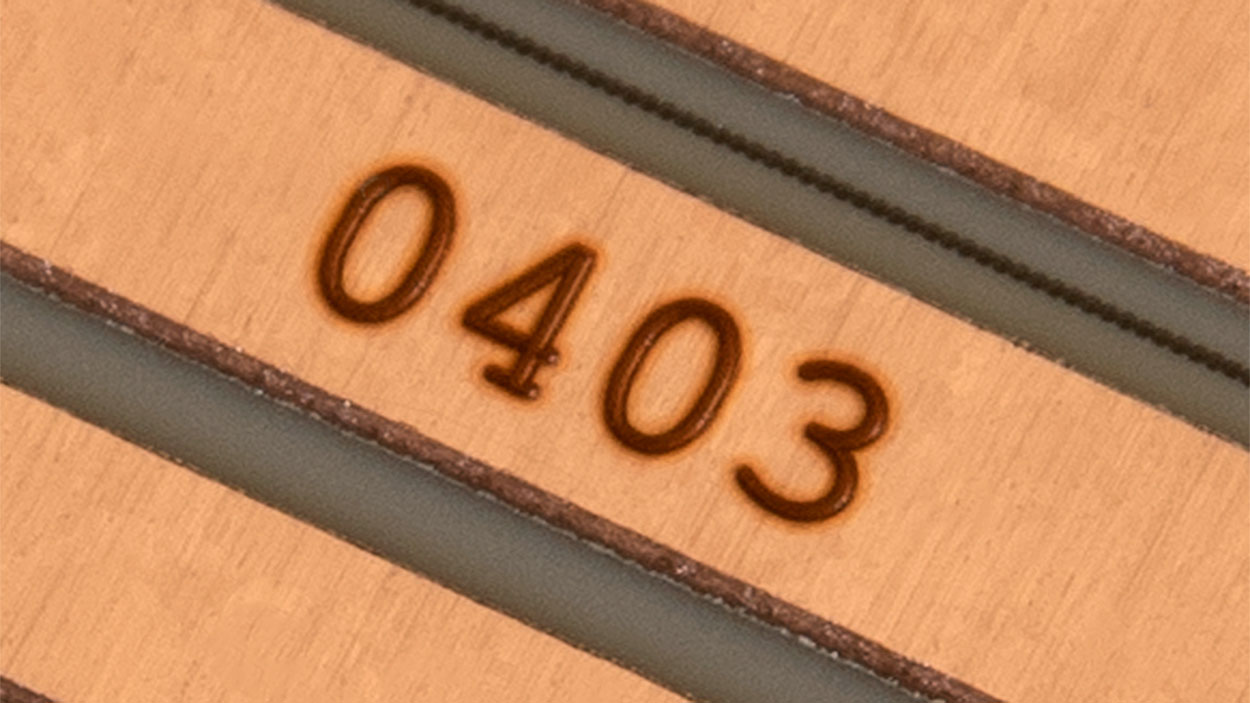

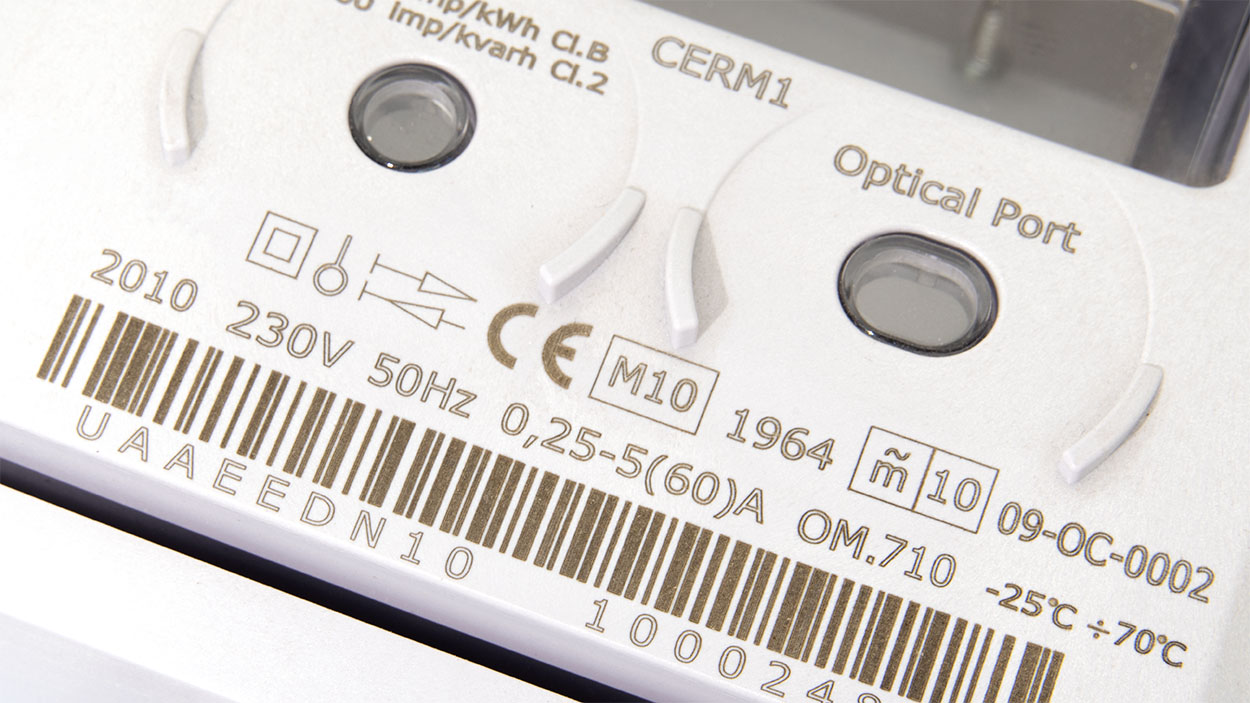

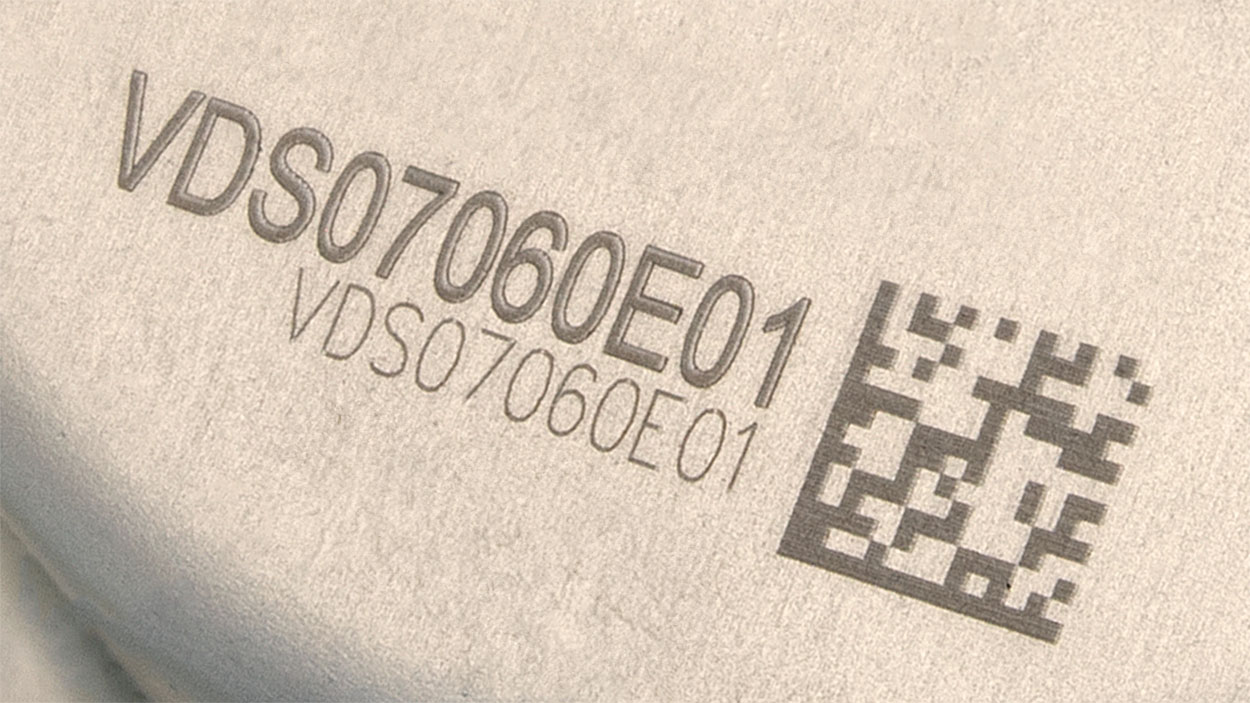

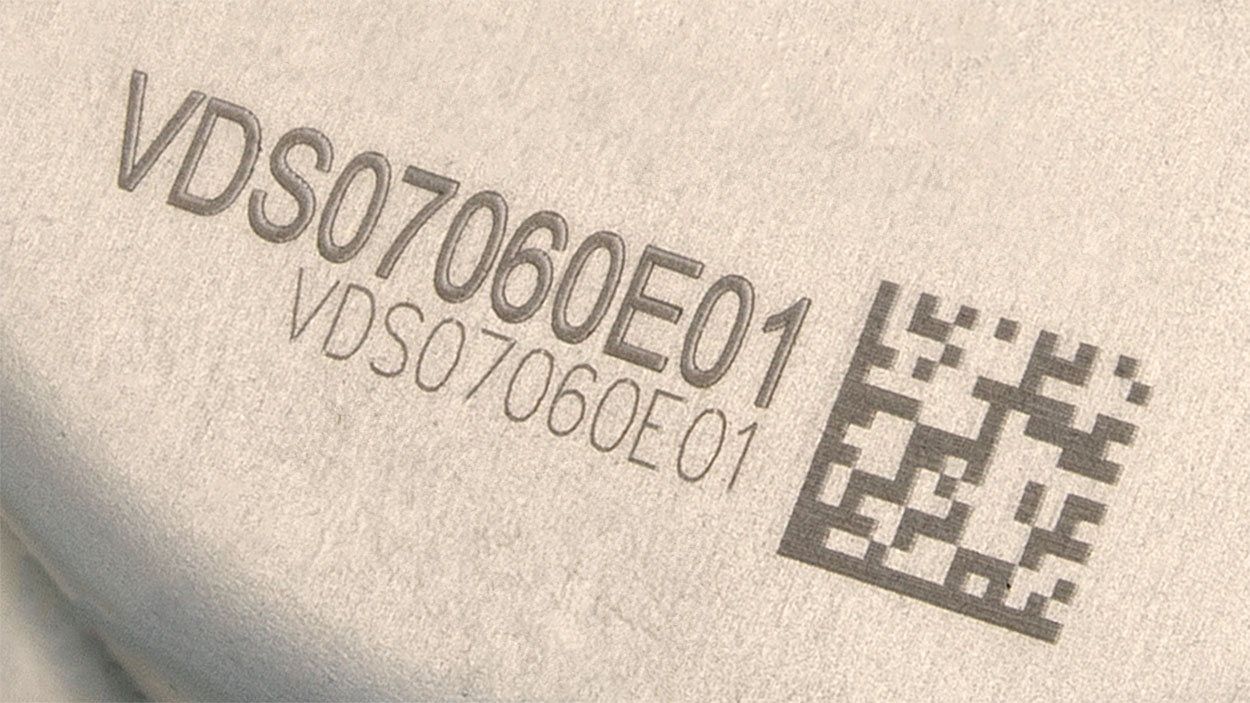

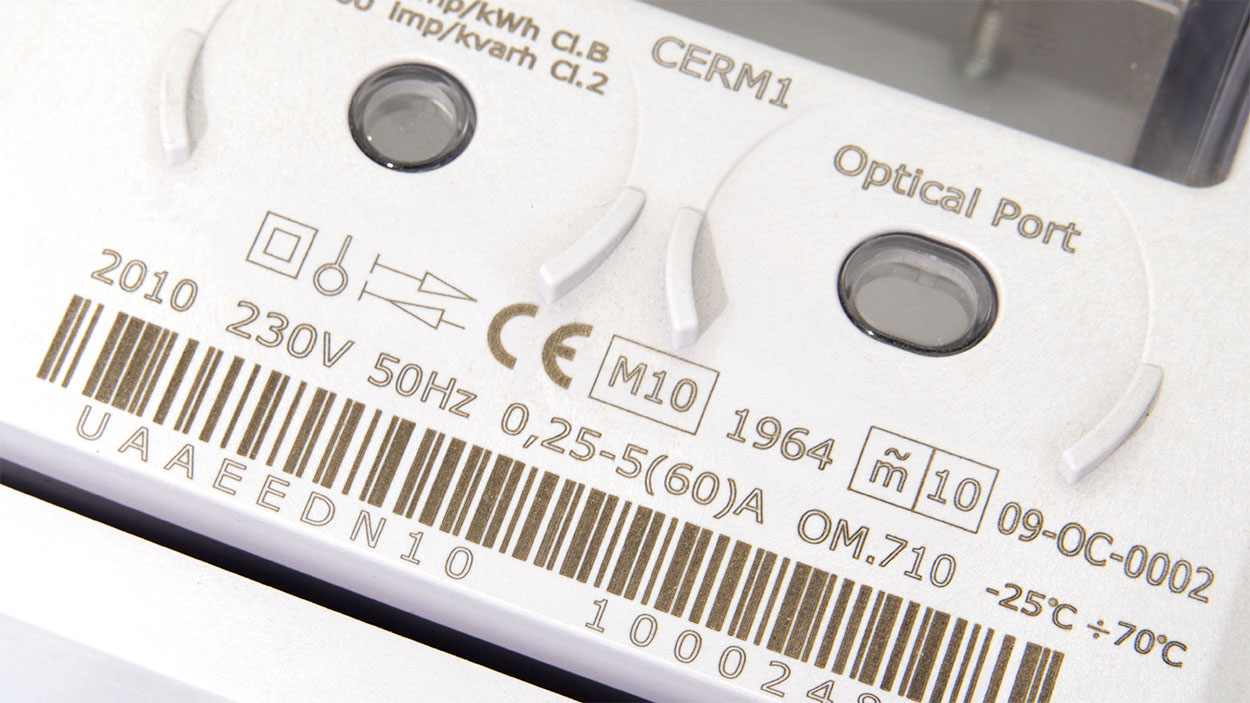

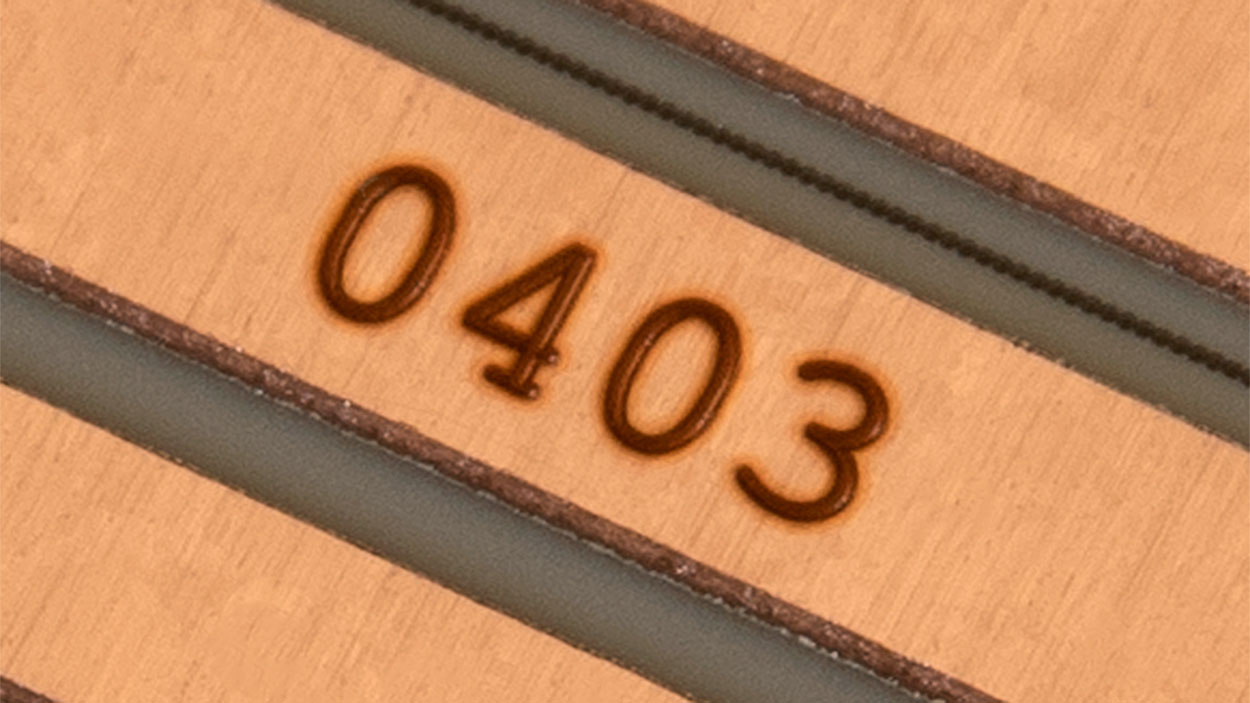

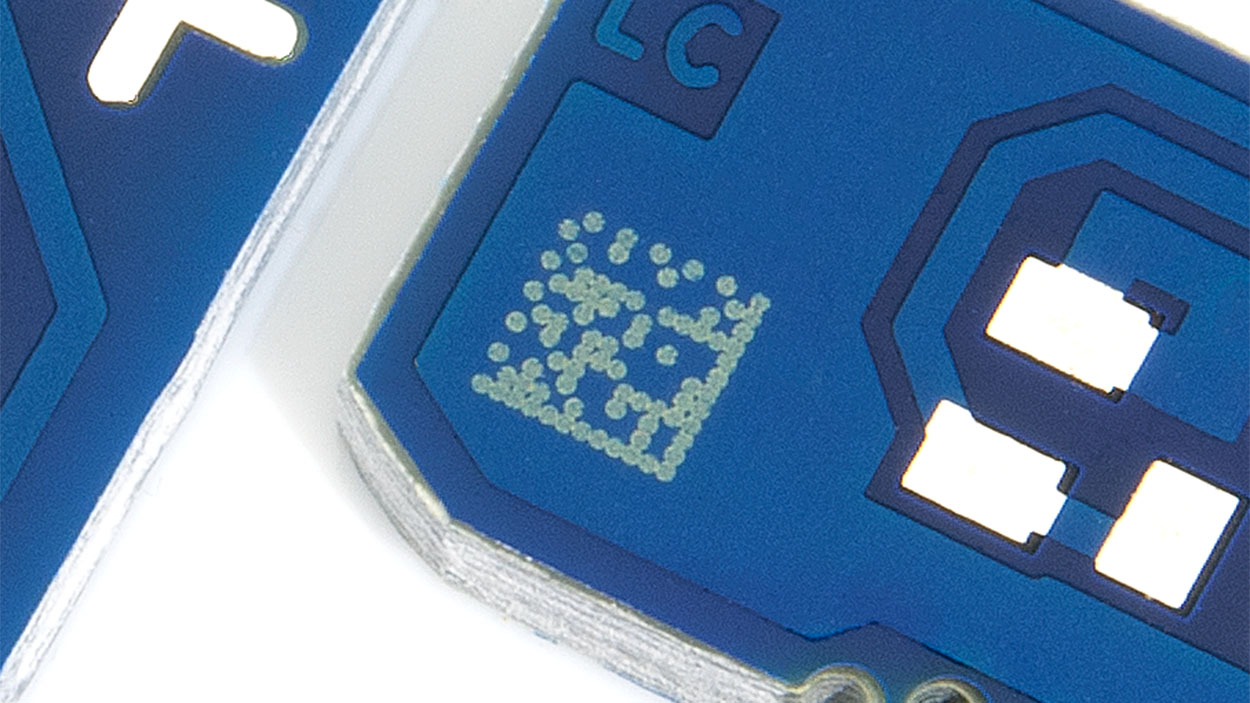

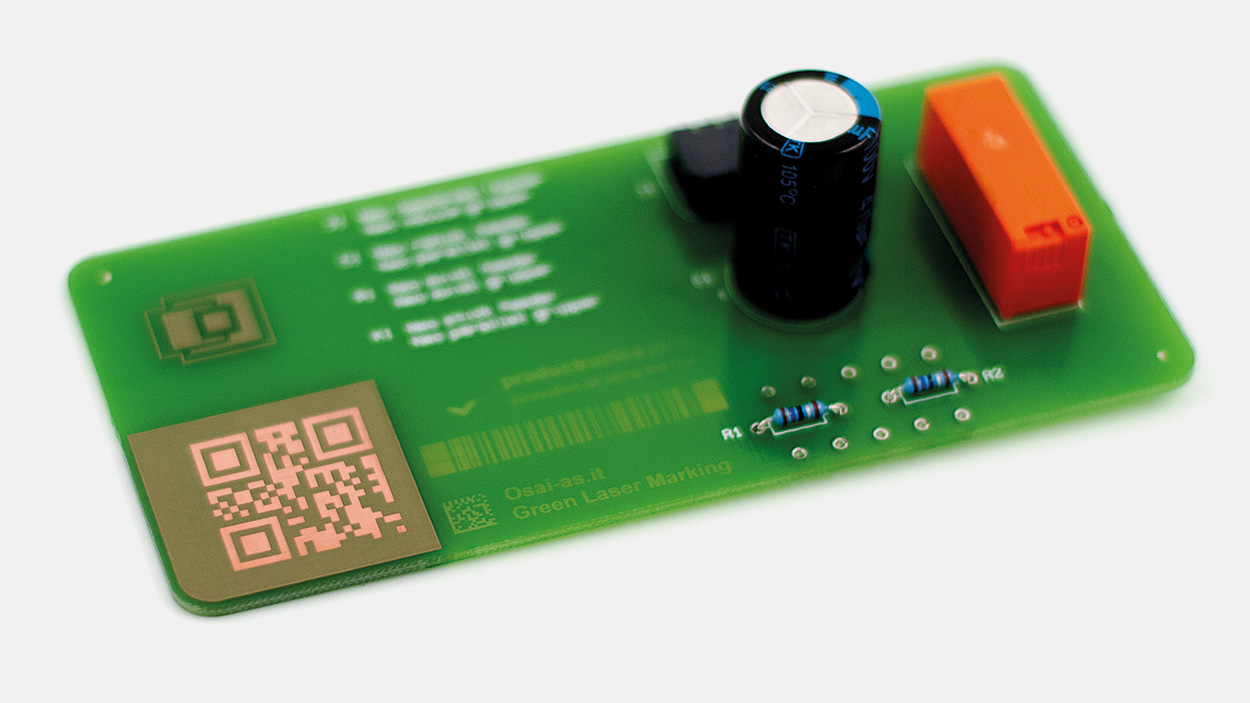

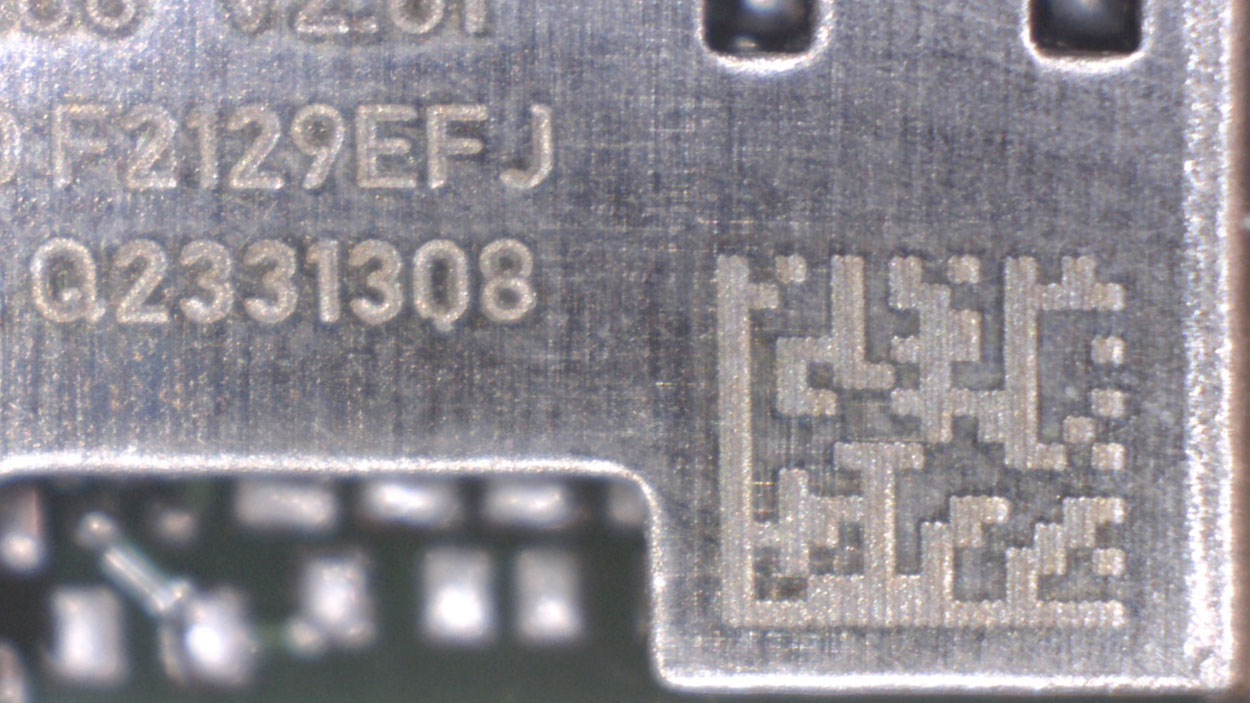

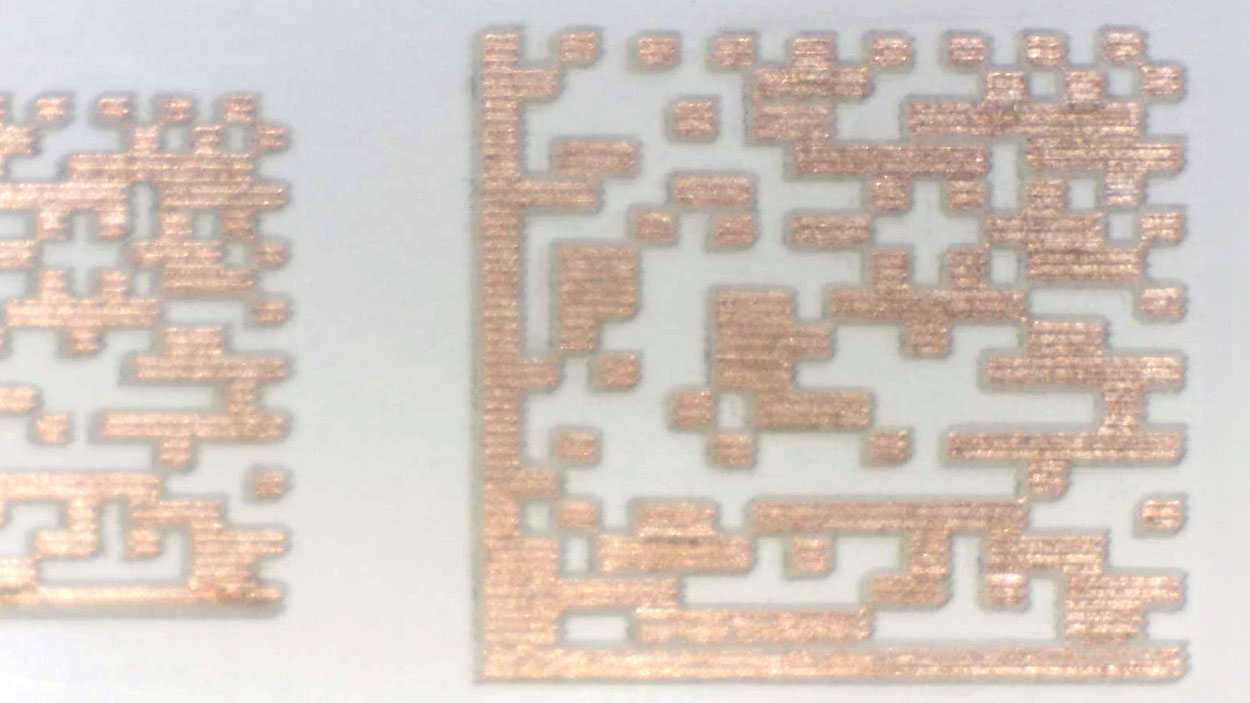

The result is a much faster cycle time compared to conventional systems. These features make the NeoMark Easy system installable directly at the SMT line or configurable as an offline ‘Marking Island’, capable of supplying pre-marked boards to the various SMT lines in the factory. The different Laser sources allow direct marking on the Solder Mask of the board or on metal and plastic components while the internal Flip Unit allows both sides of the board to be marked with a single recipe, in the same operation cycle, automatically.

The creation of working recipes (marking programs) is done easily and intuitively, thanks to the NC2 software, developed in-house. It also features the ‘board scan’, which allows the operator to scan the entire image of the board, and then insert the marking points directly on it, in a simple and visual method.

Compact system, fast cycle time

NeoMark Easy is the solution for those looking for a compact, versatile and fast marking system. The galvo head has a fixed position and covers the entire working area, with no need for external axes to move neither the board below the Laser nor the Laser above the board.

The result is a much faster cycle time compared to conventional systems. These features make the NeoMark Easy system installable directly at the SMT line or configurable as an offline ‘Marking Island’, capable of supplying pre-marked boards to the various SMT lines in the factory. The different Laser sources allow direct marking on the Solder Mask of the board or on metal and plastic components while the internal Flip Unit allows both sides of the board to be marked with a single recipe, in the same operation cycle, automatically.

The creation of working recipes (marking programs) is done easily and intuitively, thanks to the NC2 software, developed in-house. It also features the ‘board scan’, which allows the operator to scan the entire image of the board, and then insert the marking points directly on it, in a simple and visual method.