Inline fixtureless Router

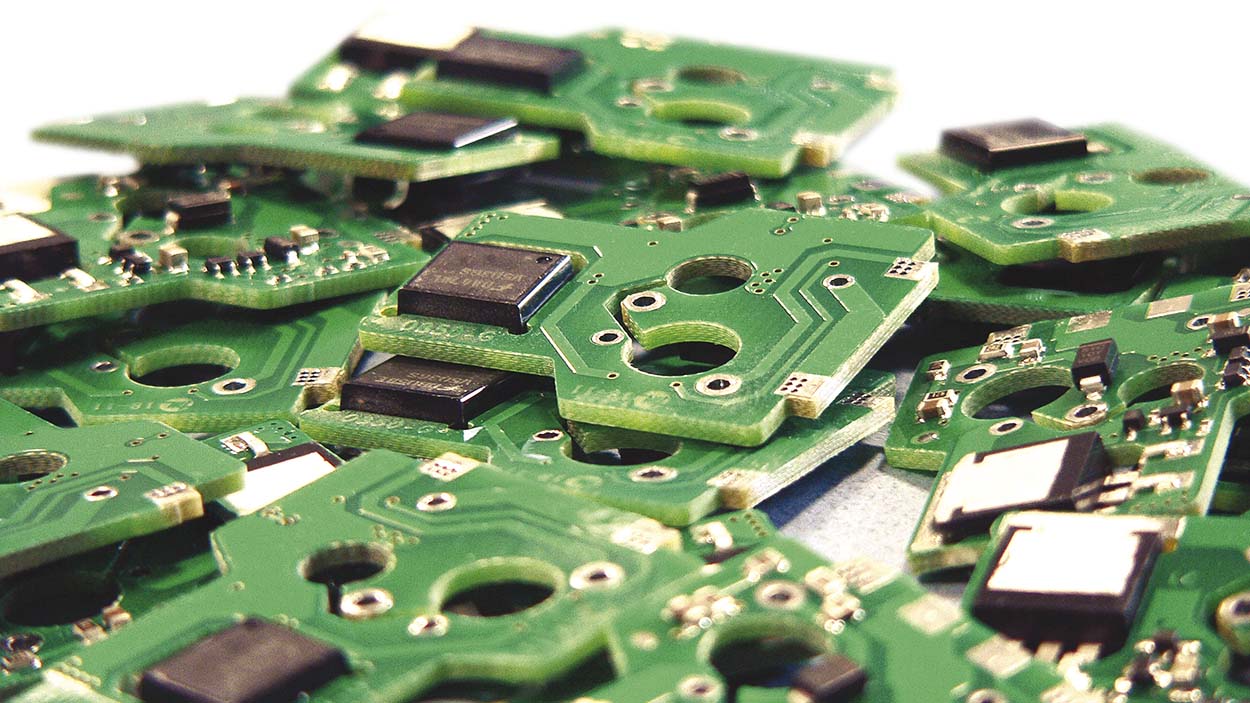

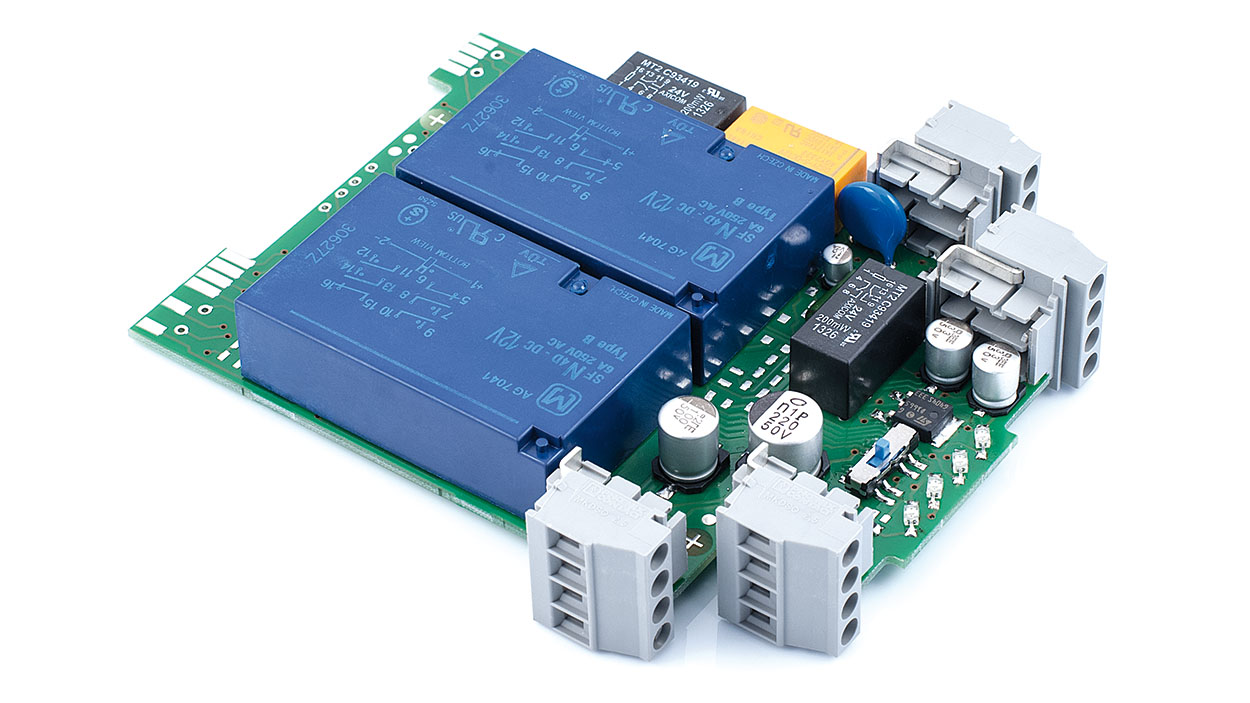

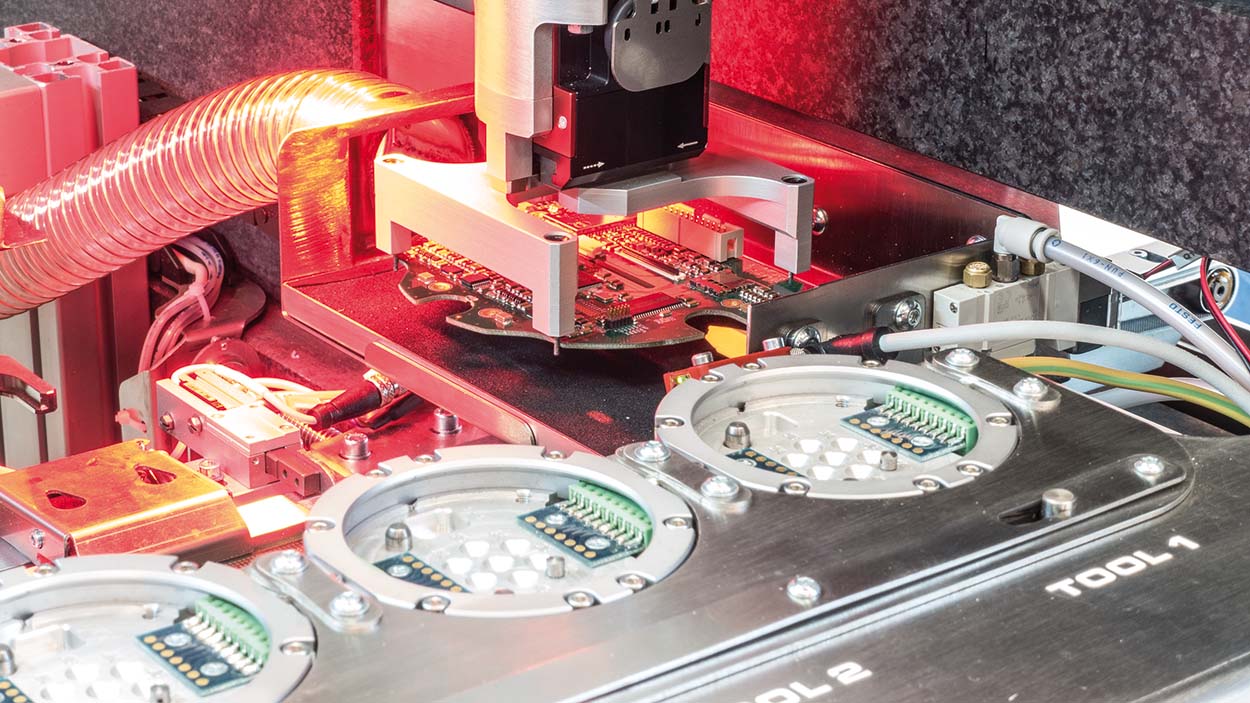

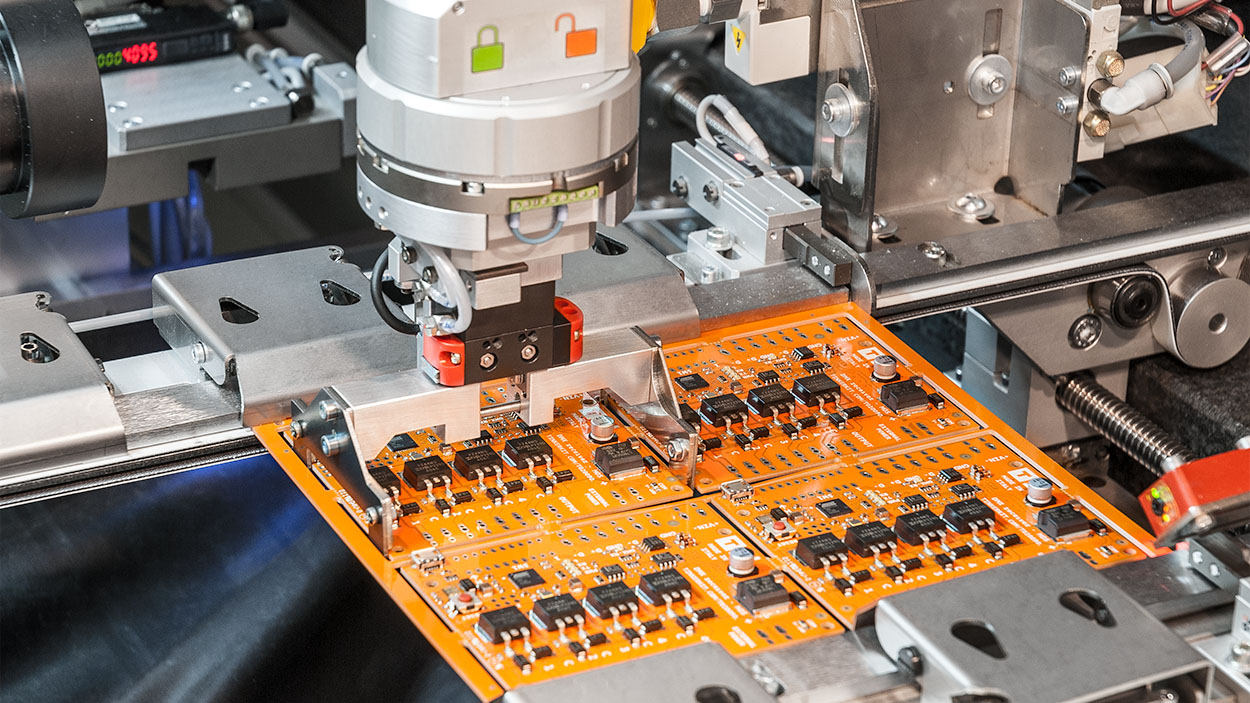

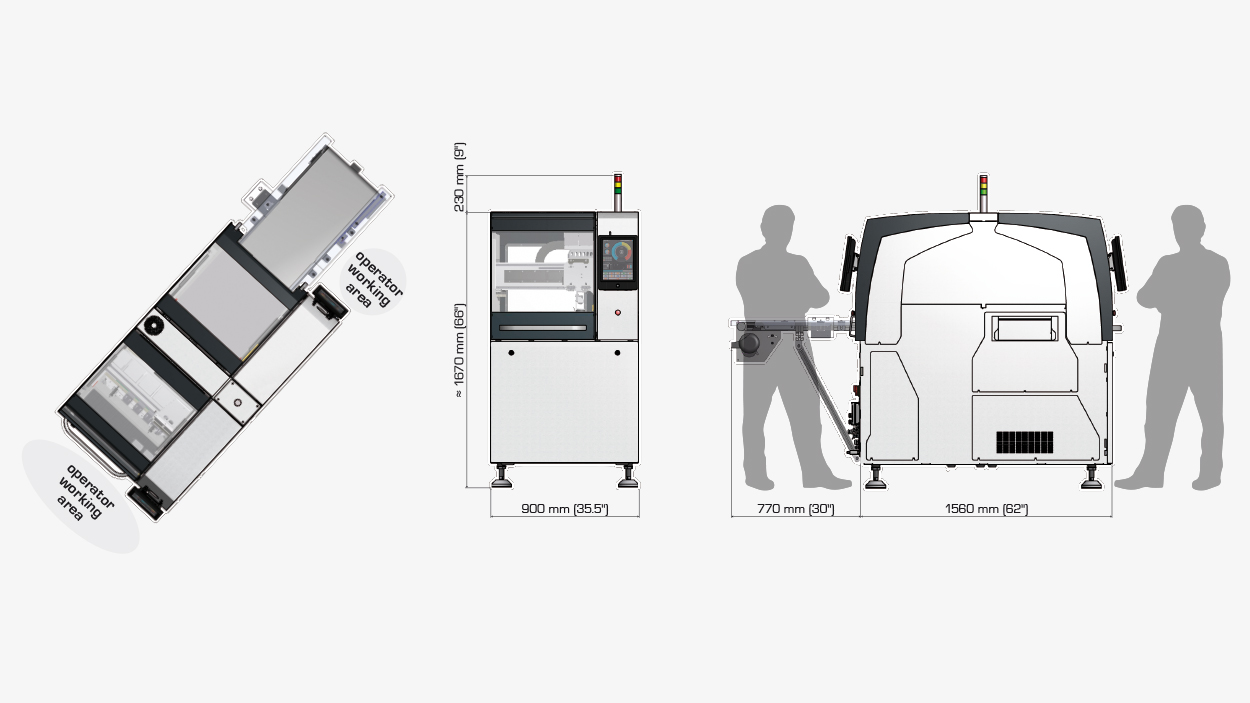

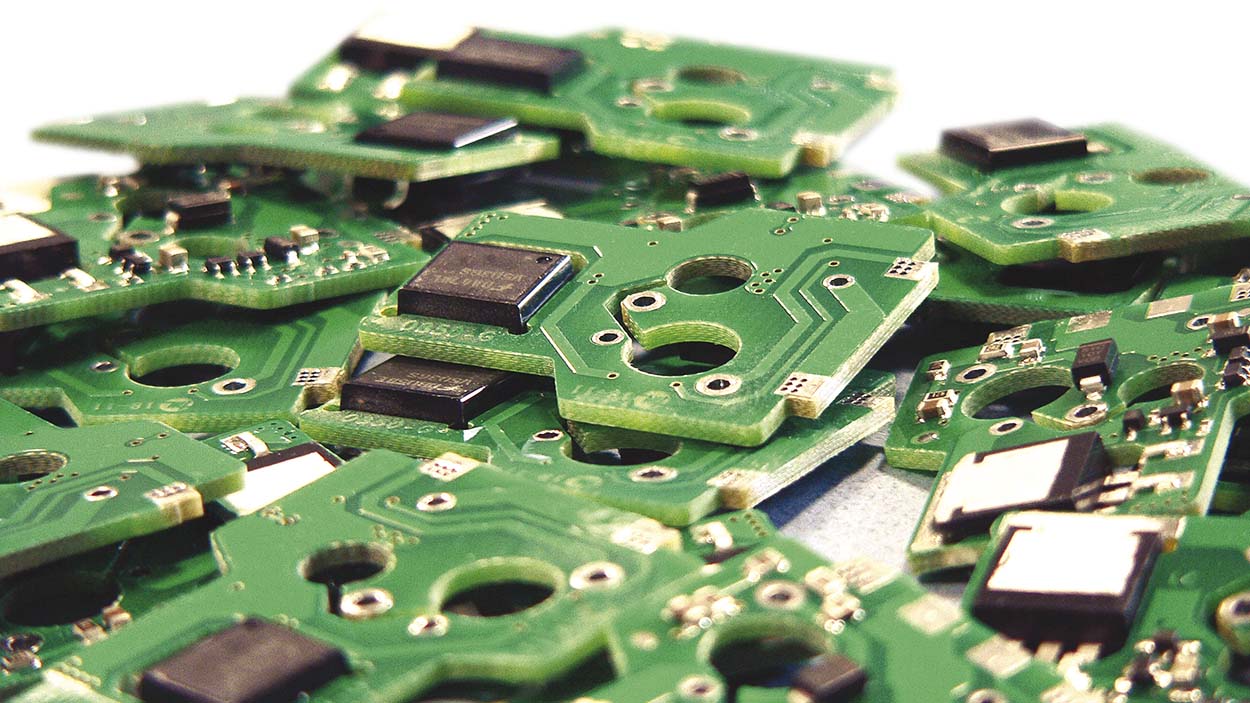

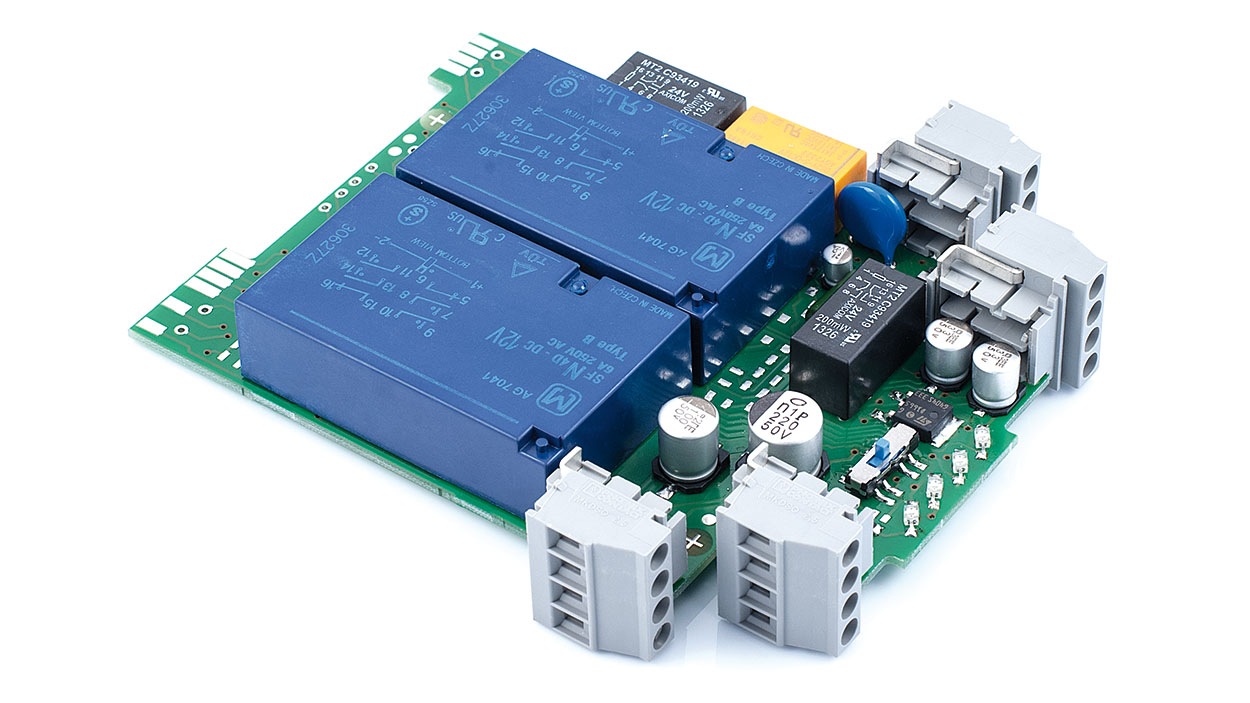

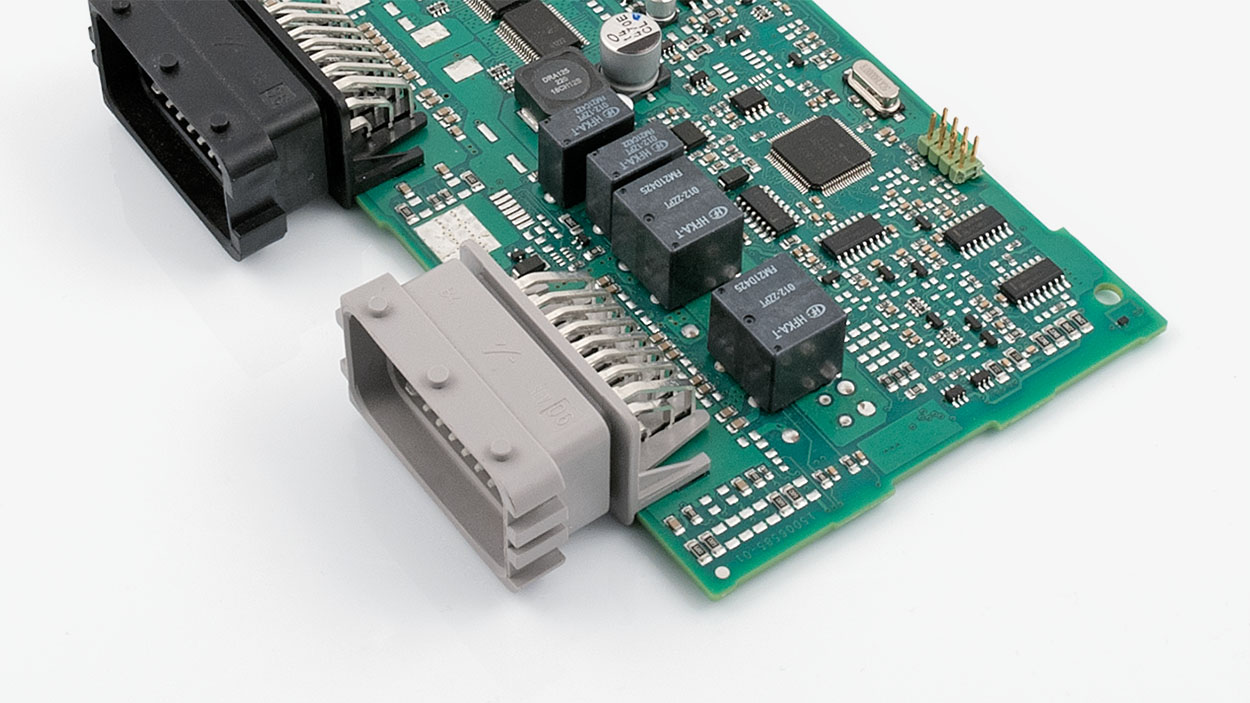

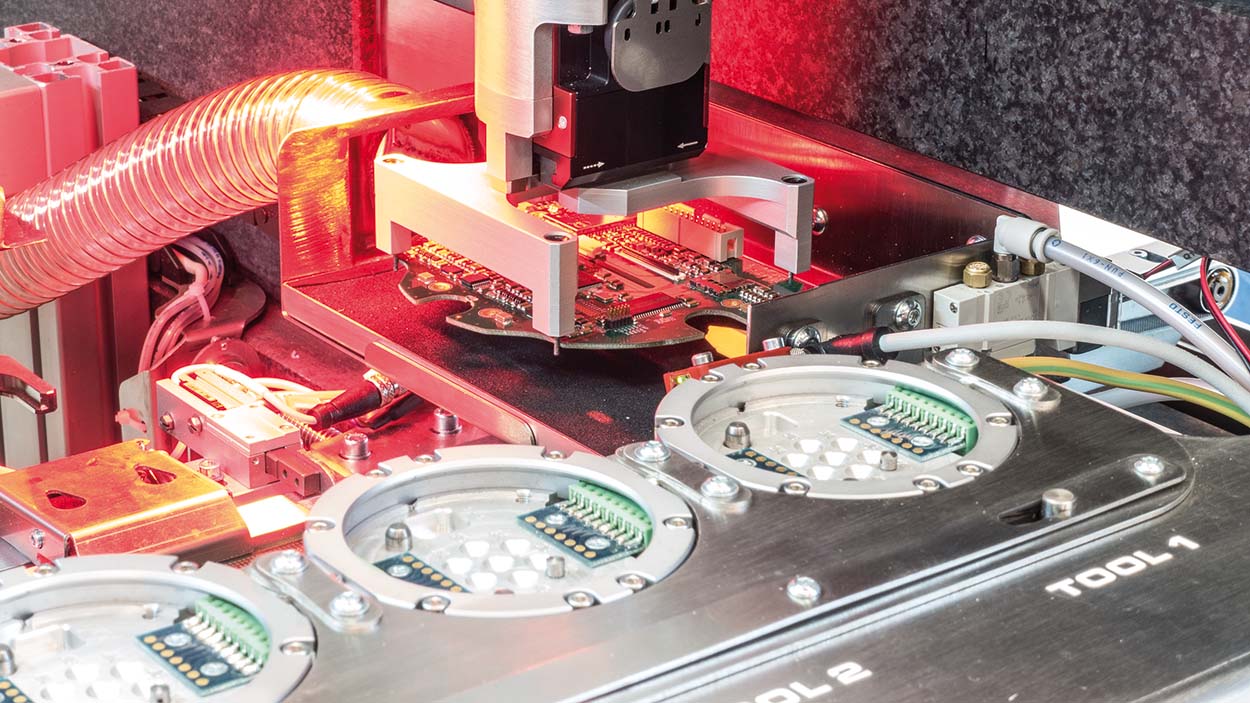

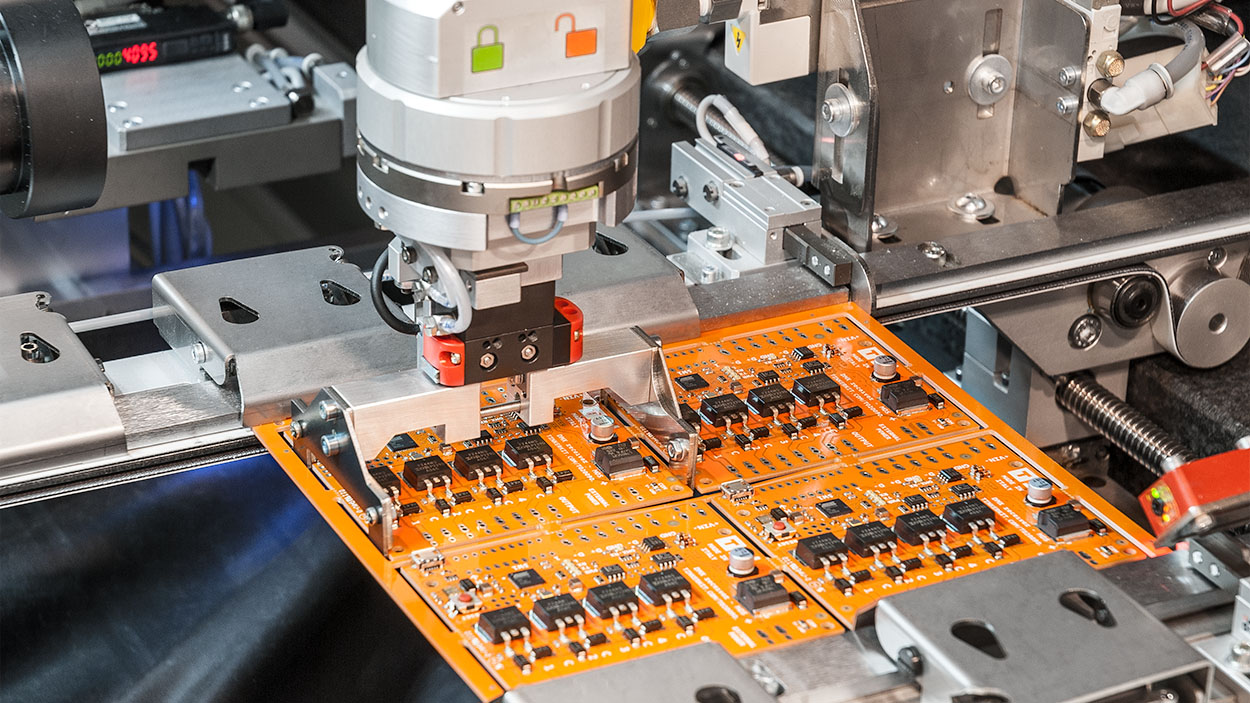

NeoRouter Modula is the solution for inline mechanical separation of PCB’s. The high flexibility in terms of configuration and fast setup make the NeoRouter Modula perfectly suitable for mass production volume, but also for high mix lots.

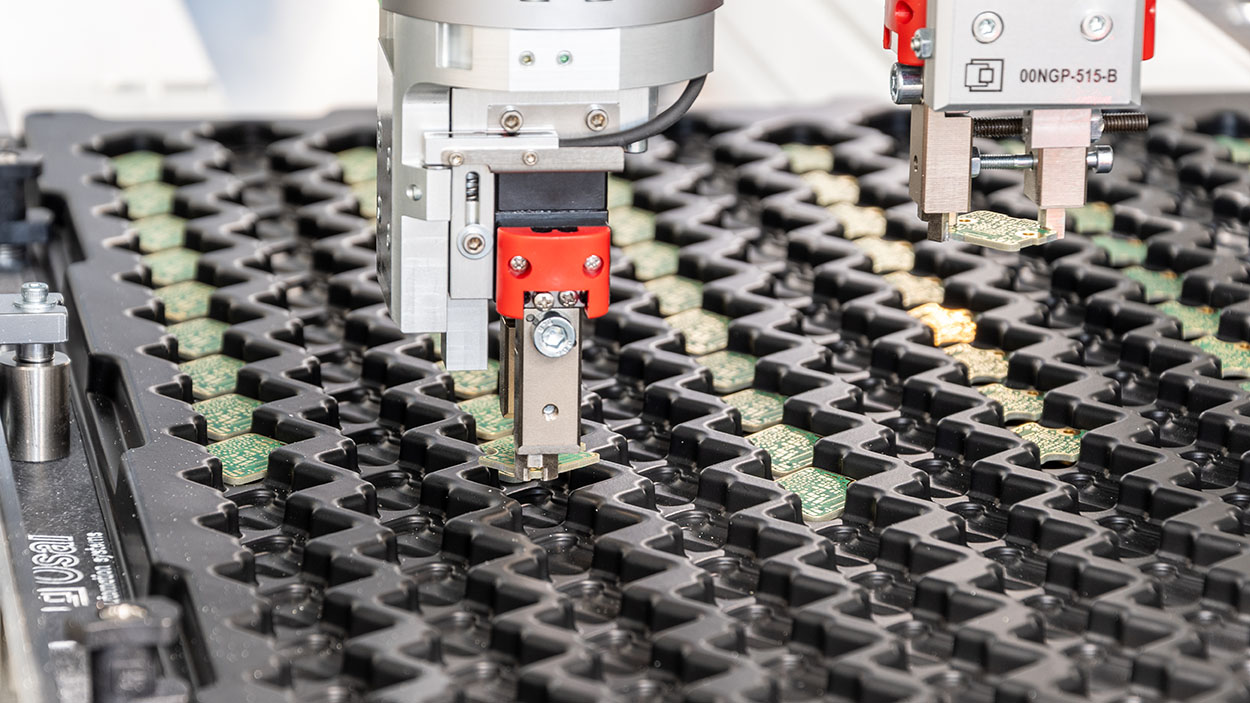

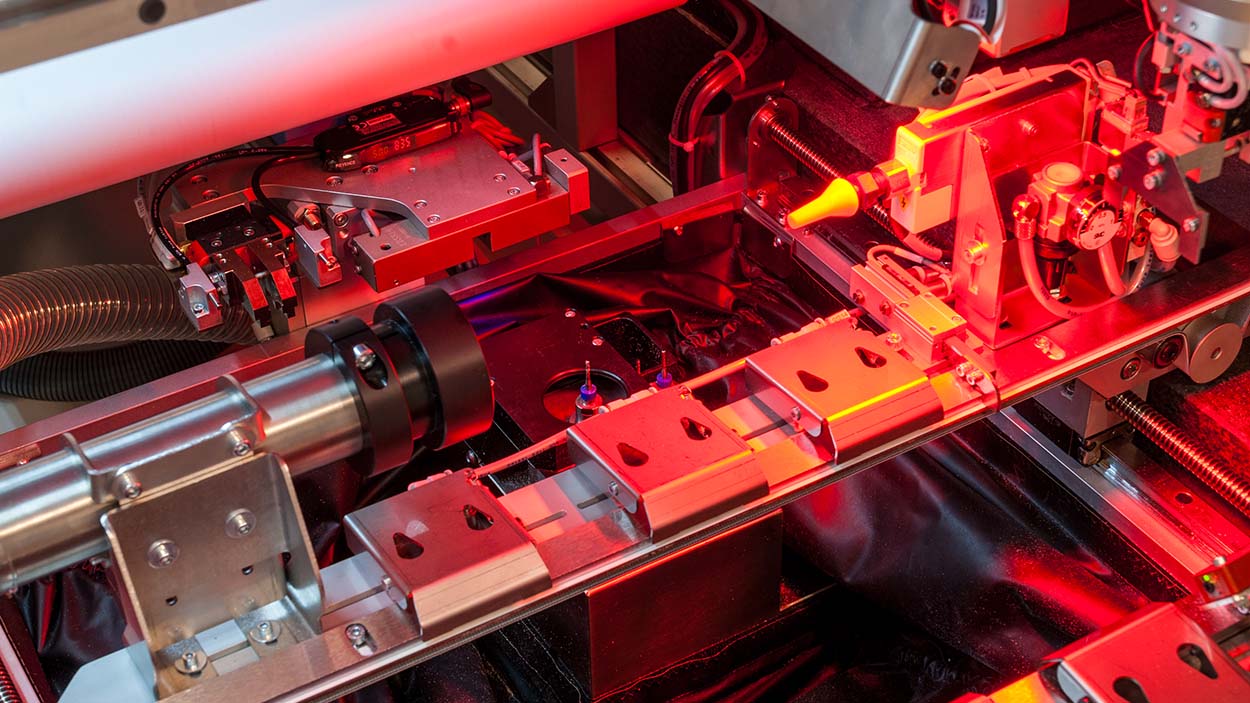

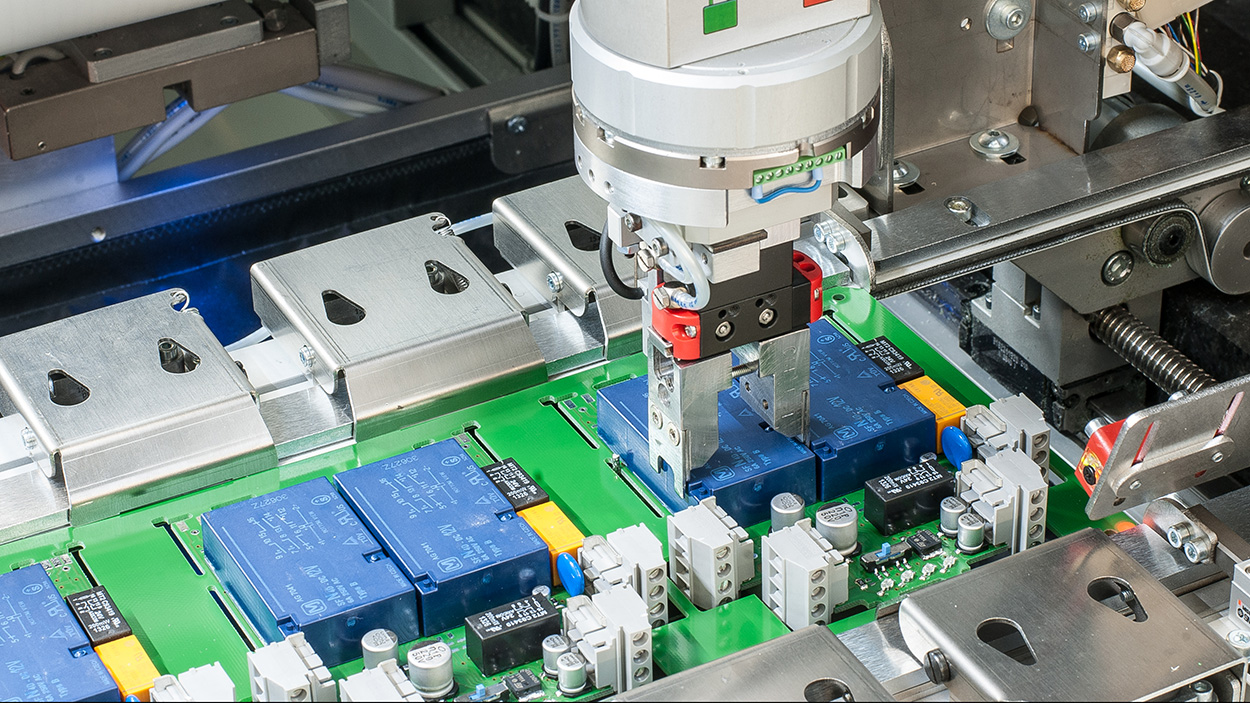

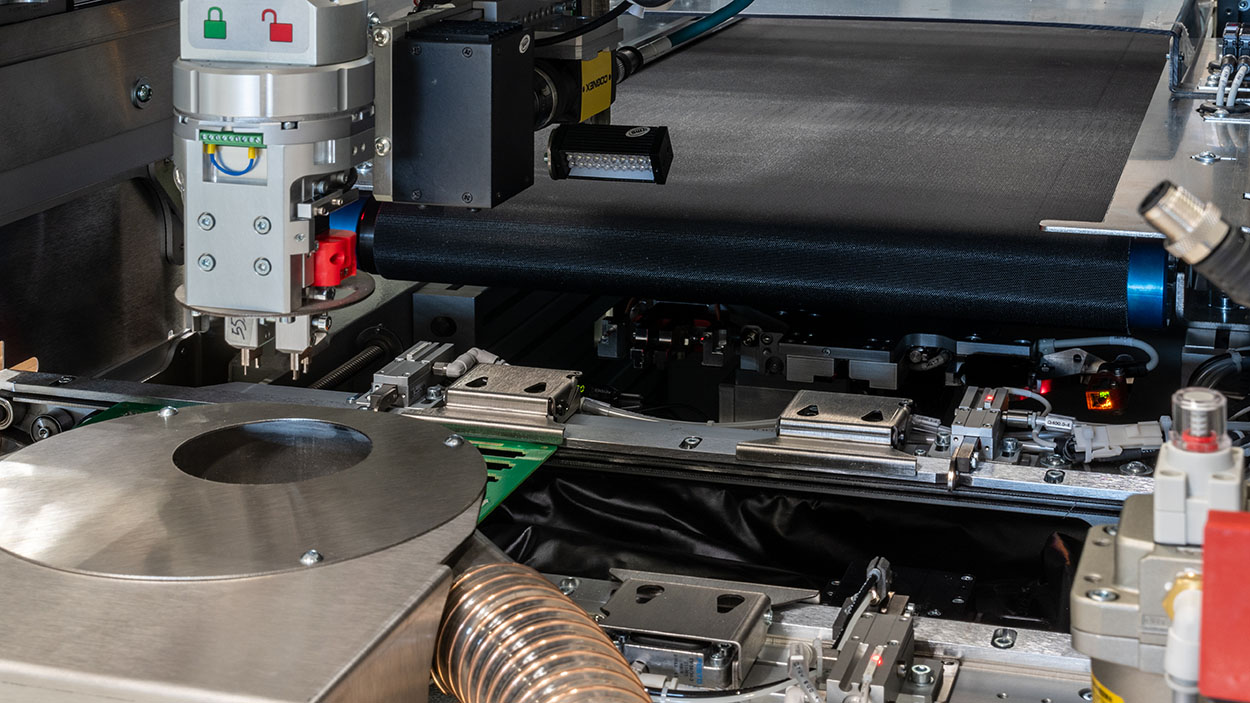

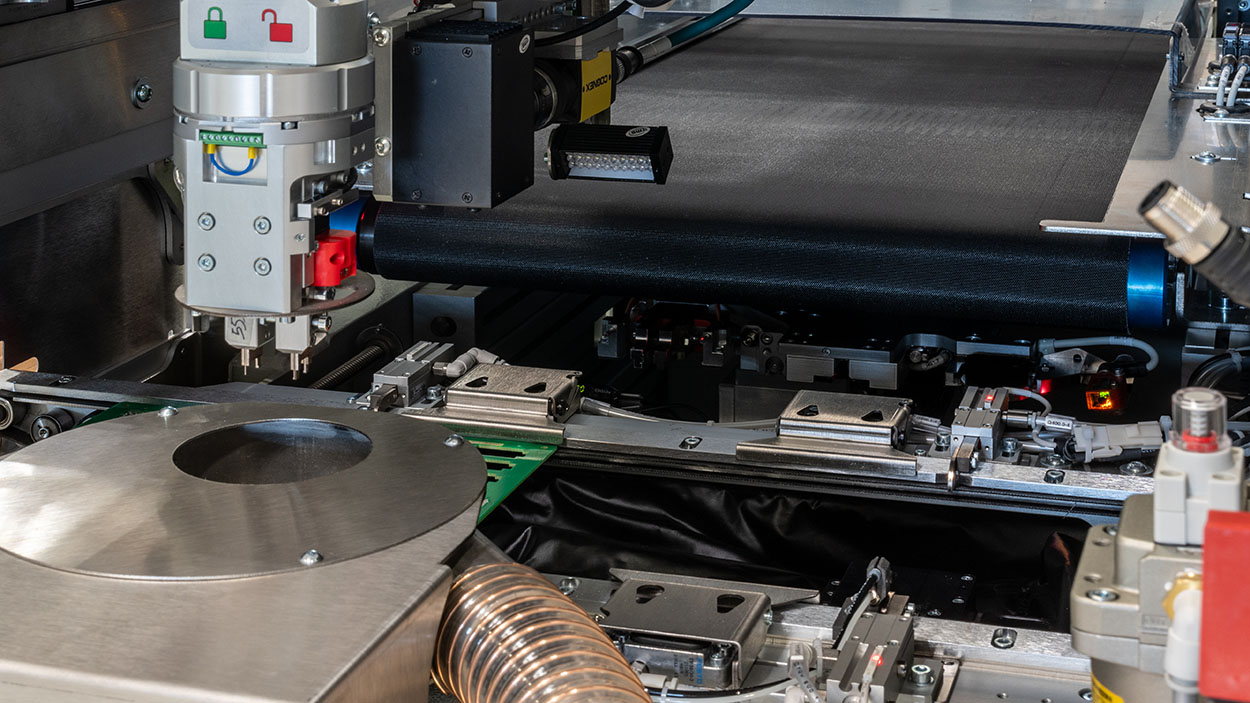

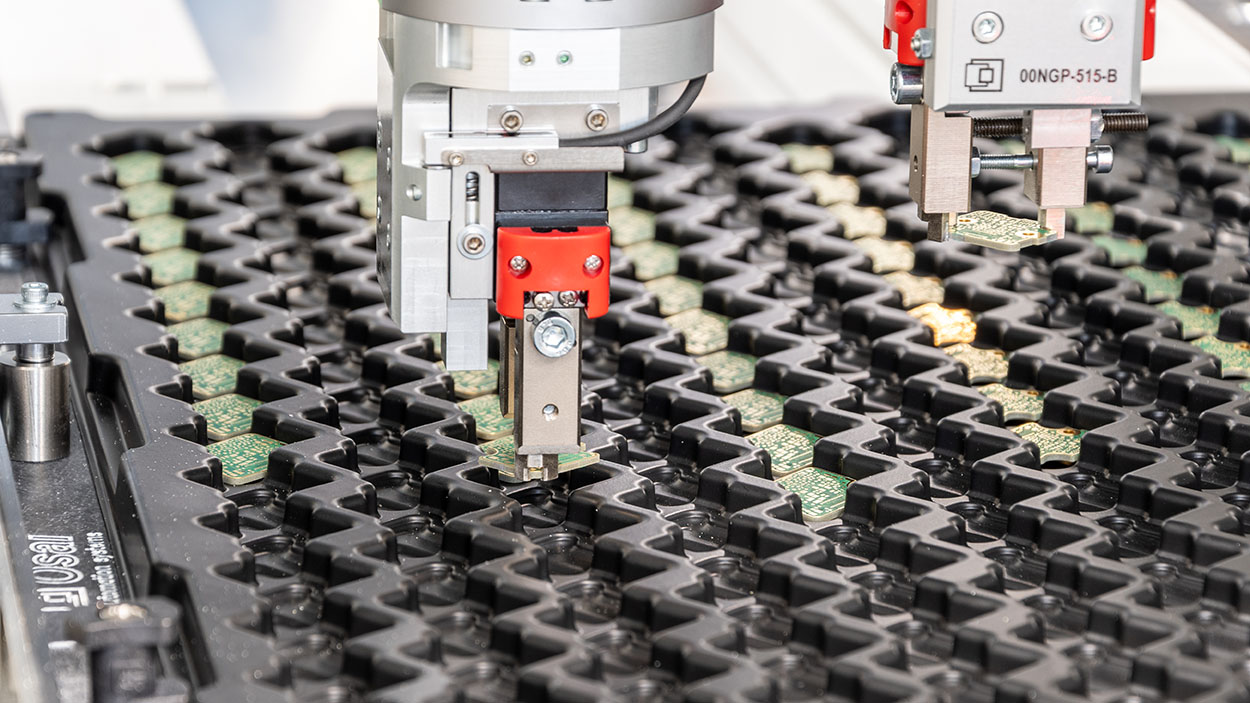

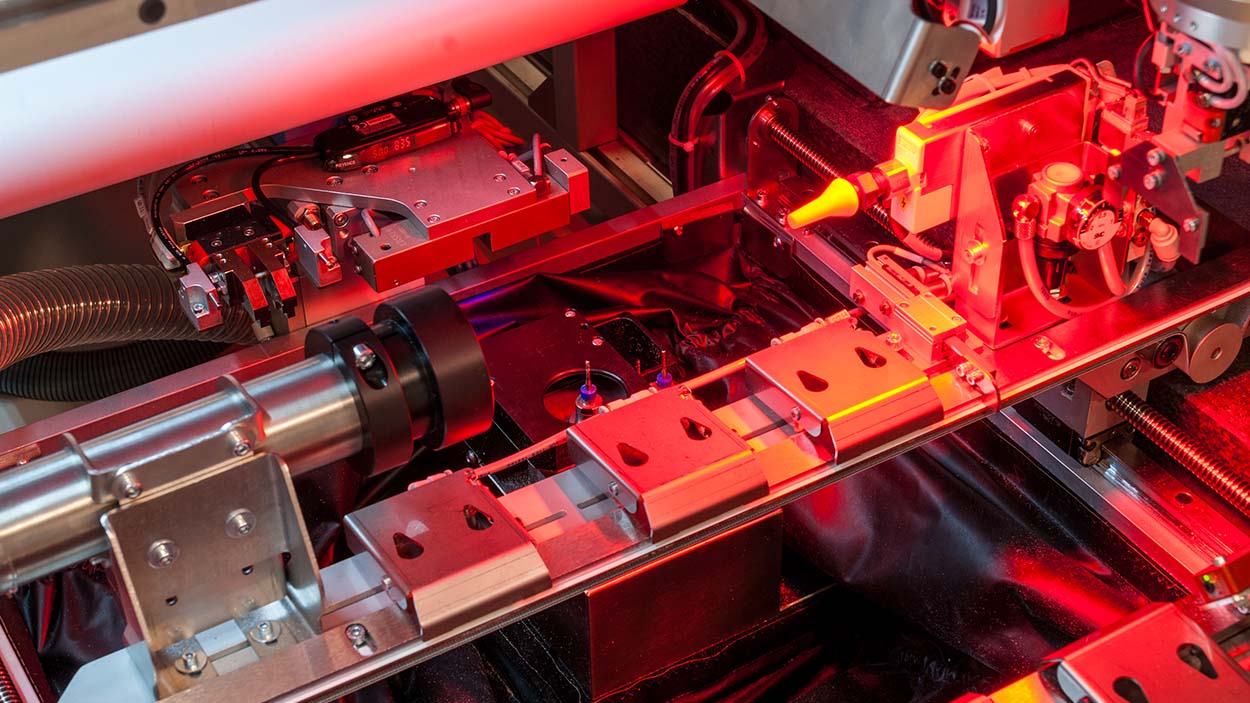

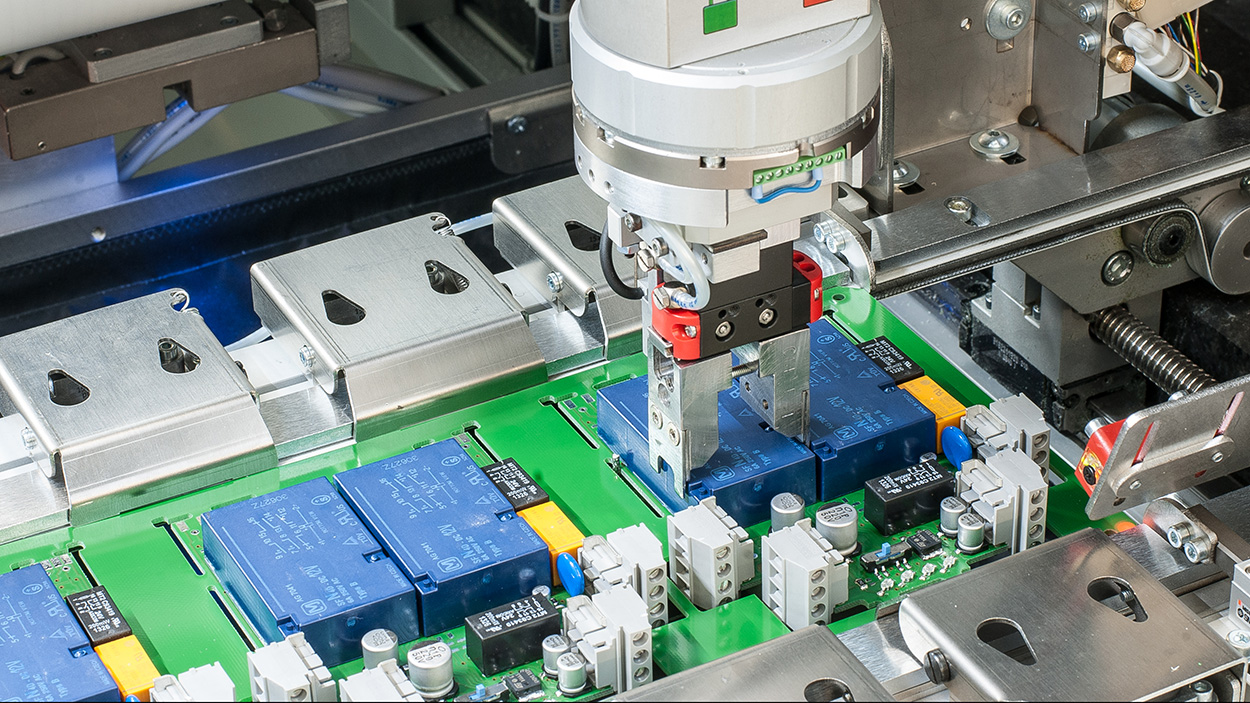

The gripper fingers can be changed manually (it takes just a few seconds) or in automatic mode (optional item). Once the right routing program is loaded, the machine is ready to start a new production lot. Routing bits are automatically changed, without any intervention from the operator and the bit presence monitoring is always active.

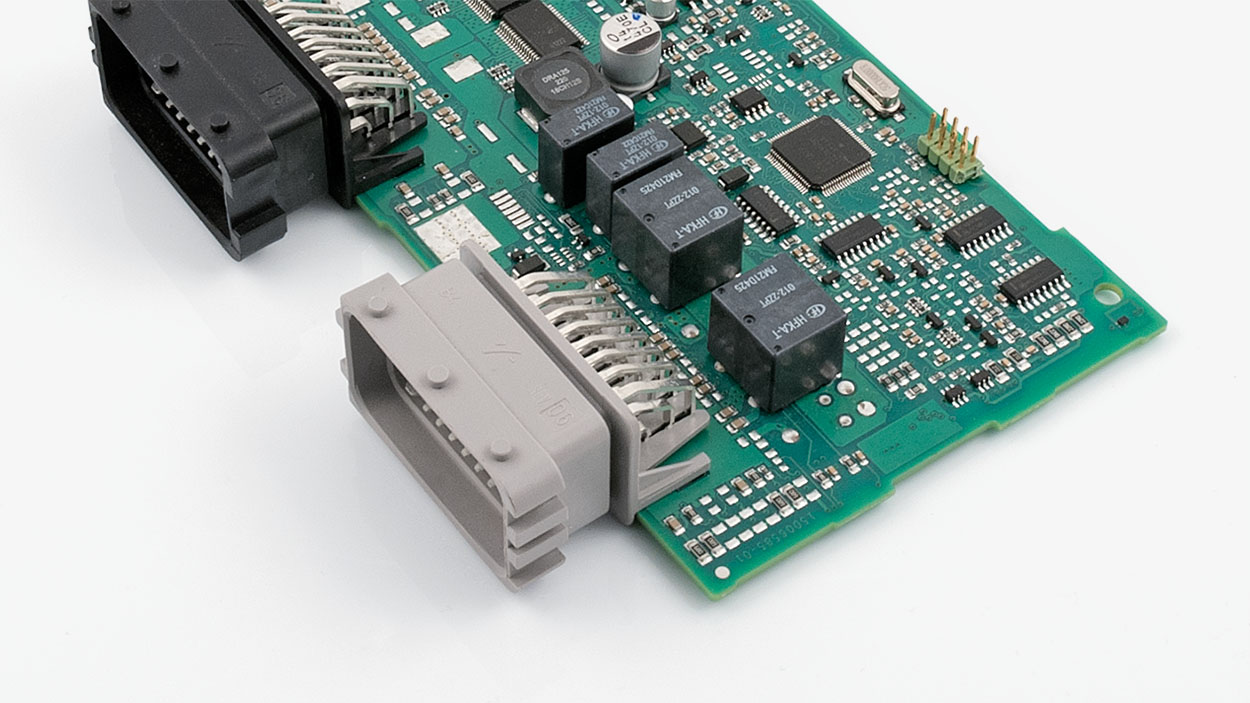

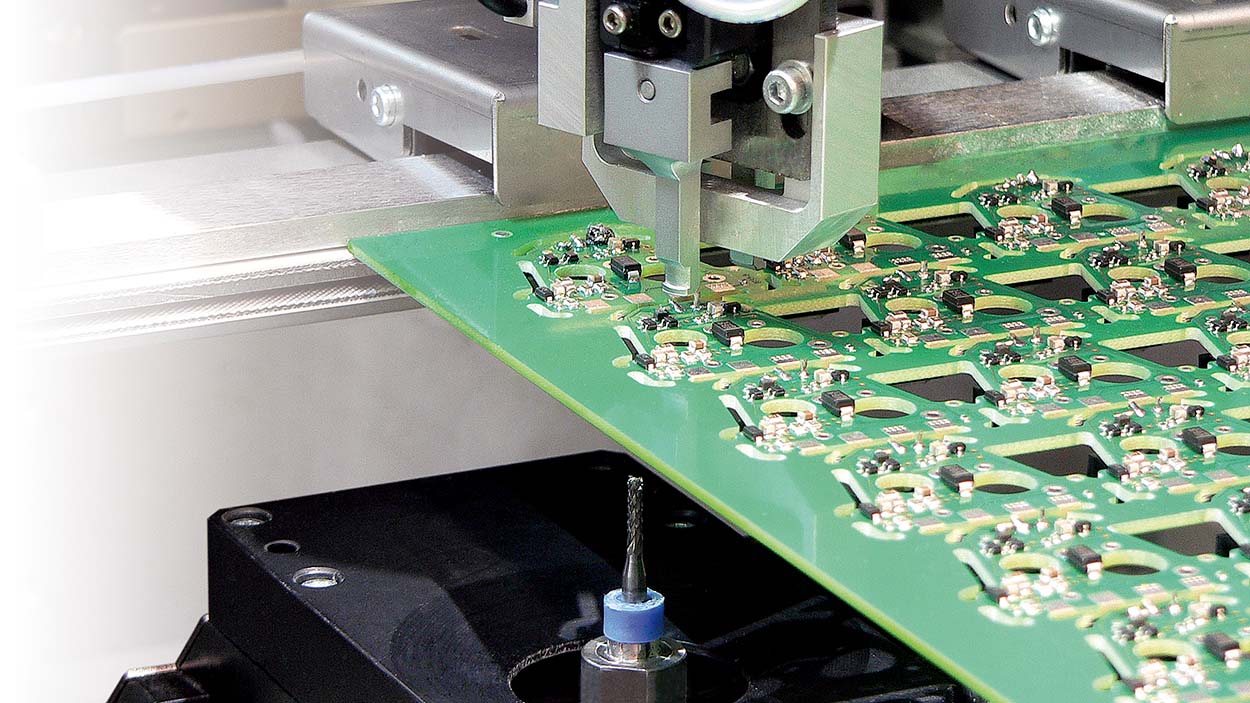

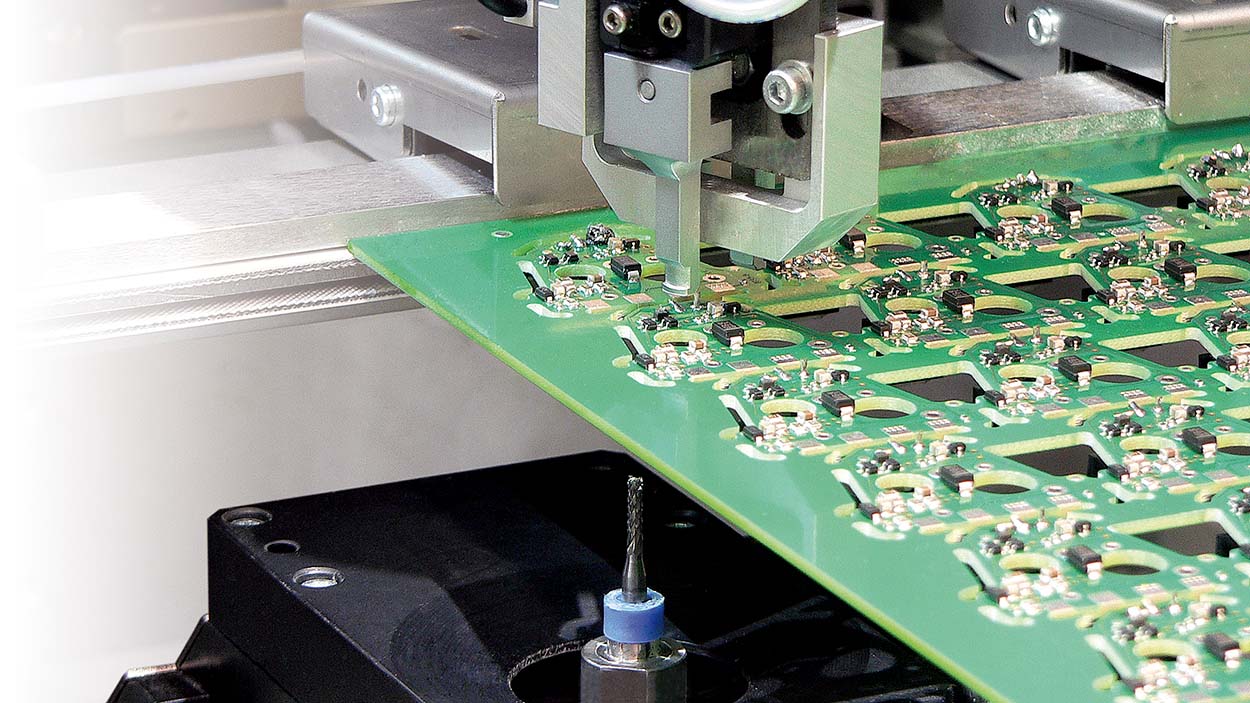

A cleaning station with ionized air can be integrated for PCB cleaning after routing, to remove dust particles. The separated PCBs can be unloaded on trays, tape conveyor or magazine racks. NeoRouter Modula can also be connected to a test equipment (ICT or AOI) or to a traceability system to automatically sort the PCBs between KO and OK. Thanks to the software operation interface, developed internally at Osai, creating router programs is fast and easy.

Inline fixtureless Router

NeoRouter Modula is the solution for inline mechanical separation of PCB’s. The high flexibility in terms of configuration and fast setup make the NeoRouter Modula perfectly suitable for mass production volume, but also for high mix lots.

The gripper fingers can be changed manually (it takes just a few seconds) or in automatic mode (optional item). Once the right routing program is loaded, the machine is ready to start a new production lot. Routing bits are automatically changed, without any intervention from the operator and the bit presence monitoring is always active.

A cleaning station with ionized air can be integrated for PCB cleaning after routing, to remove dust particles. The separated PCBs can be unloaded on trays, tape conveyor or magazine racks. NeoRouter Modula can also be connected to a test equipment (ICT or AOI) or to a traceability system to automatically sort the PCBs between KO and OK. Thanks to the software operation interface, developed internally at Osai, creating router programs is fast and easy.