Rotary table-based Laser System for plastic welding

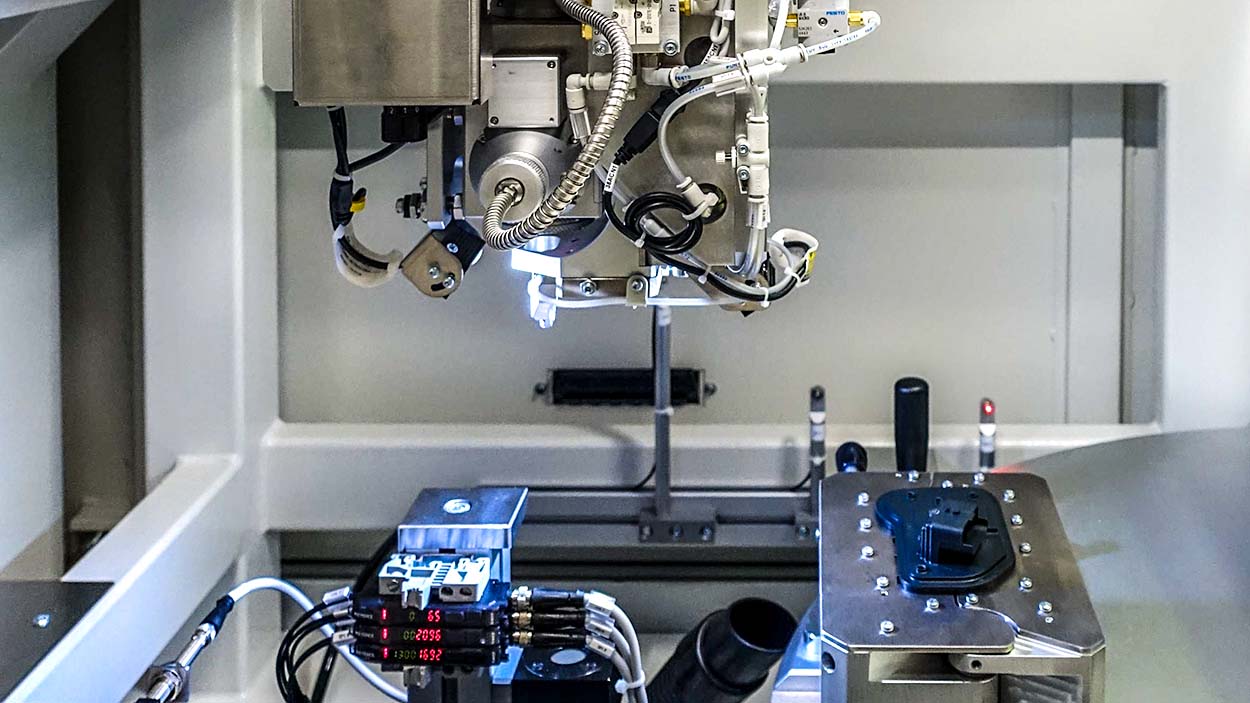

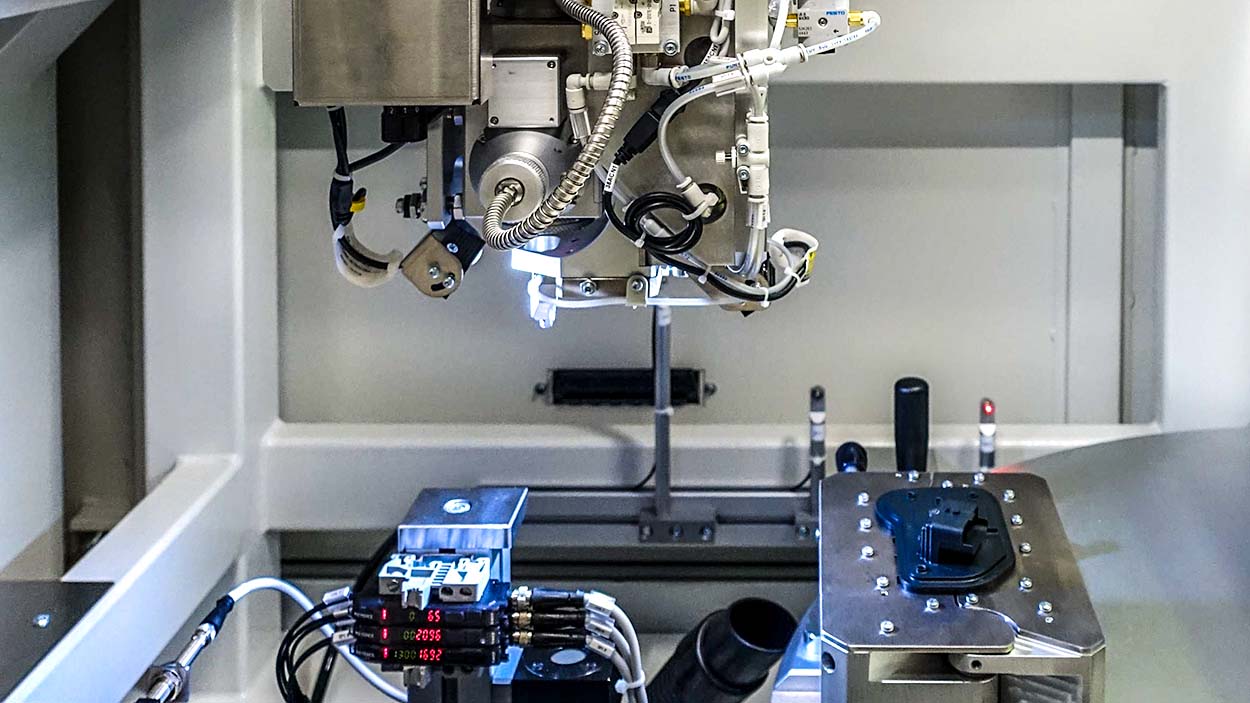

FinePlast 140R is a Class 1 Laser processing system with 700mm diameter rotary table designed for welding plastic components.

The welding process in a nutshell

Laser welding of thermoplastic materials is carried out by placing a material transparent to Laser beam in contact with an absorbent material; the absorption of the Laser radiation heats the former until it melts which in turn will melt the latter by transferring its heat. The result will be the welding of the two parts once the materials, melted together, have solidified.

The system can be customized to match the geometry of the parts to be weld with CNC-controlled axes and specific tooling to hold the parts in place by applying the right pressure.

Both contour welding and quasi-simultaneous welding using a galvanometric scanner are possible. A pyrometer system can be integrated to monitor the temperature during welding, regulating the laser power in closed loop. A vision system can also be integrated to verify the welding result.

Rotary table-based Laser System for plastic welding

FinePlast 140R is a Class 1 Laser processing system with 700mm diameter rotary table designed for welding plastic components.

The welding process in a nutshell

Laser welding of thermoplastic materials is carried out by placing a material transparent to Laser beam in contact with an absorbent material; the absorption of the Laser radiation heats the former until it melts which in turn will melt the latter by transferring its heat. The result will be the welding of the two parts once the materials, melted together, have solidified.

The system can be customized to match the geometry of the parts to be weld with CNC-controlled axes and specific tooling to hold the parts in place by applying the right pressure.

Both contour welding and quasi-simultaneous welding using a galvanometric scanner are possible. A pyrometer system can be integrated to monitor the temperature during welding, regulating the laser power in closed loop. A vision system can also be integrated to verify the welding result.