NEOHANDLER

Mass Production

Test Handler for MEMS

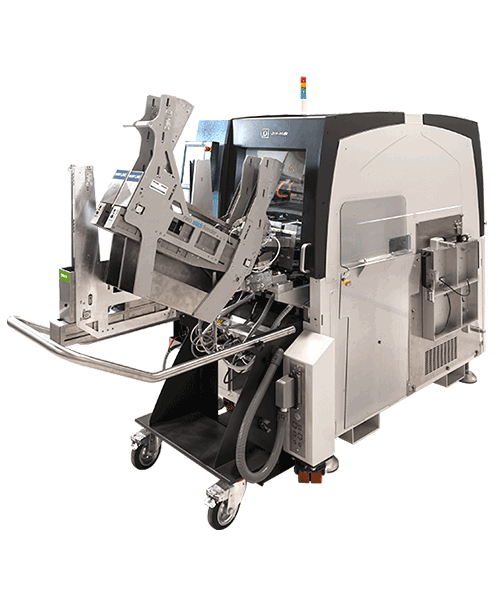

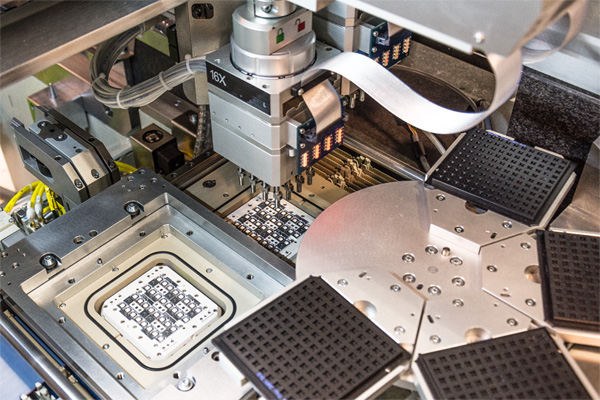

OSAI NeoHandler è una soluzione di prim’ordine per le aziende produttrici di semiconduttori, per il testing di MEMS e dispositivi di potenza in produzione di massa (fino a 25KUPH).

NeoHandler produce basse emissioni: l’area di produzione 900 x 1.600mm salva spazio, aumentando drasticamente il rendimento (UPH / m2), utilizzando il concetto di scalabilità. L’alta flessibilità consente al cliente di modificare la configurazione in 15 minuti, massimizzando l’investimento: il carrello di input / output può essere sostituito con diversi tipi di caricatori e gli attrezzi per il multi pick-up possono essere semplicemente scalati secondo il bisogno.

La vasta gamma di attrezzi multi-presa e multi pick-up sviluppato da OSAI consente ai clienti di gestire diversi pacchetti.

NeoHandler può essere configurato correttamente con diverse camere di stimolo, a seconda dei MEMS specifici da condizionare.

PLAY VIDEO

DOWNLOAD DATA SHEET

Punti Chiave

Dispositivi riconosciuti

La NeoHandler nasce come proposta generica per il test.

In ogni caso, la compatibilità dipende dai contattori.

La NeoHanlder è compatibile con i seguenti tipi di dispositivo:

HANDLING

REAR SIDE TRAYS INPUT OUTPUT TROLLEY:

OSAI NeoHandler è dotato di un carrello di input/output.

Le opzioni di carrello sono state realizzate in modo da poter essere modificate ogni qualvolta sia necessaria una riconfigurazione di handler, riducendo così i tempi di configurazione.

Un dispositivo con cambio rapido con un sistema di auto-allineamento meccanico, garantisce la ripetibilità dell’input/output.

I carrello possono essere configurati con diversi tipi di soluzioni di alimentazione input/output.

Input:

- Jedec Tray Feeder

- Tube

- Bowl

- Film frame

Output:

- Jedec Tray

- Tube

- T&R

- Bowl

TOOLS

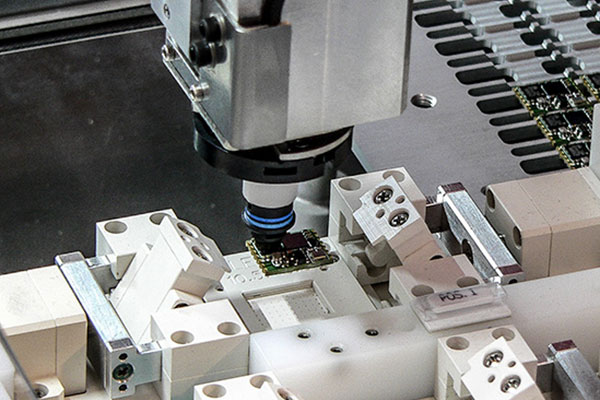

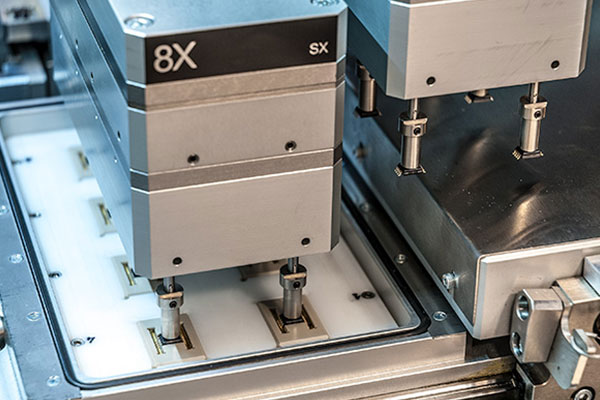

SPECIFICI PICK-UP TOOL PER OGNI TESTA

Le principali caratteristiche dei Pick-Up tools sono:

- Cambio rapido (meno di 1 minuto) e Interfaccia OSAI standard (include tutte le connessioni elettriche e pneumatiche)

- 1, 4, 8, 16, 35 siti, altri multi-siti disponibili in futuro

- Linea Z indipendente da 10mm su ciascun picker

- Comando e controllo del vuoto indipendente su ciascun picker

- Flusso d’aria staccabile e finemente regolabile

- Sensore di collisione sito singolo

- Dispositivo di precisione su pickerper pre-allineamento dispositivo

- Codice interno per verifica configurazione ricetta

NEO-TLAB

Attrezzature da laboratorio per MEMS ambientali

La Neo T-LAB è la soluzione di laboratorio OSAI di ultima generazione. Grazie alle sue dimensioni compatte, la Neo T-LAB è la camera di condizionamento più piccola e performante disponibile sul mercato.

Oltre al minimo ingombro, la Neo T-LAB offre la possibilità di essere configurata con diversi stimoli di prova, quali temperatura, pressione, umidità e gas.

È possibile progettare la Neo T-LAB su misura, in base alle esigenze del cliente, passando così dal laboratorio alla produzione in pochi semplici passi.

PLAY VIDEO

DOWNLOAD DATA SHEET

Punti Chiave

STIMOLI

ENGINEERING PRESSURE CHAMBER

PRINCIPALI CARATTERISTICHE

- Range di temperatura: -20° fino a 80°C o -40° fino a 125°C

- Precisione temperatura: 0,5°C

- Stabilità temperatura: 0,3°C

- Tempo medio di stabilizzazione: 10s

- Range di pressione: da 0 a 6bar

- Tempo di stabilizzazione pressione: 3s

- Stabilità di pressione: in base al regolatore esterno

- Comunicazione MEMS Protocollo: SPI, I2C, GPIO

- Interfaccia PC: USB

STIMULI

HIGH ACCURATE STIMULI

- Thermal stimuli unit

- Pressure stimuli unit

- Gas stimuli unit

- Humidity stimuli unit

NEOHANDLER

Mass Production

Test Handler for MEMS

OSAI neohandler is the top-notch solution for Semiconductor Companies, for testing MEMS and Power devices in mass production (up to 25KUPH). Neohandler small footprint 900 x 1.600mm saves production area, increasing drastically the throughput (UPH / m2), by using scalable concept.

High flexibility allows the customer to change setup in 15 minutes, maximizing the investment: Input / output trolley can be replaced with different magazine type and Multipick up tool can be easily and simply scaled according to the need.

The wide range of Multisocket and multipick up tools developed by OSAI, allows the customers to manage different packages. Neohandler can be properly configured with different Stimulus Chambers, according to specific MEMS to be conditioned.

PLAY VIDEO

DOWNLOAD DATA SHEET

Handler’s Keypoints

Acceptable devices packages

The Handler is conceived as a general purpose equipment.

However the full compatibility for a certain package is given from the contactors.

The Handler is compatible with the following packages:

HANDLING

REAR SIDE TRAYS INPUT OUTPUT TROLLEY:

The Handler is equipped with an input/output trolley.

Trolley is conceived to be changed on field to reduce the setup time in case of a Handler re-configuration.

A fast changing system with a mechanical self alignment system guarantees the input output repeatability.

Trolley can be configured with different kinds of input output feeding.

Input:

- Jedec Tray Feeder

- Tube

- Bowl

- Film frame

Output:

- Jedec Tray

- Tube

- T&R

- Bowl

TOOLS

EACH HEAD IS EQUIPPED WITH A SPECIFIC PICK-UP TOOL

Main characteristics of the Pick-Up tools are:

- Fast changing (less than 1 minute) and standard Osai interface (includes all the electrical and pneumatic connections)

- 1, 4, 8, 16, 35 sites, other multisite available on the roadmap

- Independent 10mm Z stroke each single picker

- Independent vacuum command and control on each single picker

- Fine adjustable detaching air blow

- Single site collision sensor

- On picker precisor for device pre-alignment

- Internal code for setup-recipe verification

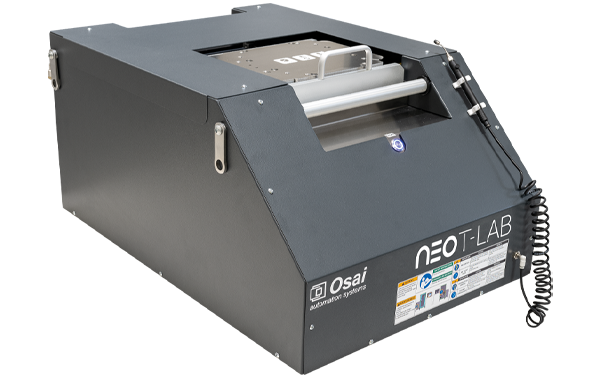

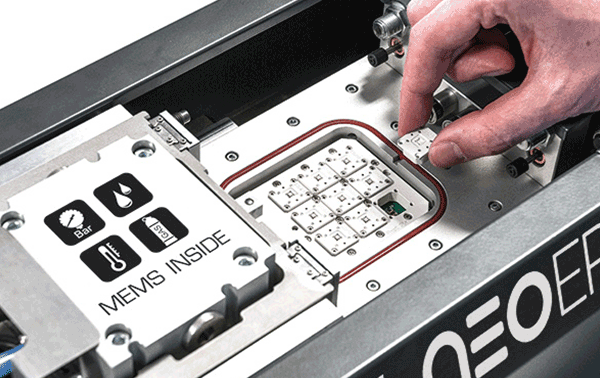

NEOT-LAB

Lab Equipment for environmental MEMS

Neo T-LAB is OSAI’s ultimate desk size lab test solution. With its compact size Neo T-LAB is the smallest conditioning chambers in the world allowing the R&D fine tuning directly in laboratory.

In addition to the smallest footprint, the Neo T-LAB advanced offers the possibility to be configured with several test stimuli, such as temperature, pressure, humidity and gas.

Neo T-LAB is also a tailor made solution: the possibility to design the test chamber based on customer needs, allows the transition from laboratory to mass production in just few steps.

PLAY VIDEO

DOWNLOAD DATA SHEET

EPC’s Keypoints

STIMULI

ENGINEERING PRESSURE CHAMBER

MAIN CHARACTERISTICS

- Temperature range: -20° up to 80°C or -40° up to 125°C

- Temperature accurancy: 0,5°C

- Temperature stability: 0,3°C

- Average setting time: 10s

- Pressure range: 0 up to 6bar

- Pressure setting time: 3s

- Pressure stability: according to external regulator

- MEMS communication protocol: SPI, I2C, GPIO

- PC Interface: USB

STIMULI

HIGH ACCURATE STIMULI

- Thermal stimuli unit

- Pressure stimuli unit

- Gas stimuli unit

- Humidity stimuli unit

NEOHANDLER

Massenproduktion

Testhandler für MEMS

OSAI NeoHandler ist die erstklassige Lösung für Halbleiterunternehmen, um MEMS- und Power-Bauelemente in der Massenproduktion (bis zu 25KUPH) zu testen.

NeoHandler hat eine kleine Standfläche: Die Produktionsfläche von 900 x 1.600 mm ist raumsparend und drastisch erhöht den Durchsatz (UPH/ m2) durch die Skalierbarkeit. Die hohe Flexibilität ermöglicht es dem Kunden, die Einrichtung in 15 Minuten zu ändern, wodurch die Investition maximiert wird: Der Ein-/Ausgabewagen kann durch verschiedene Magazintypen ersetzt werden und Multipick up Werkzeuge können einfach und leicht nach Bedarf skaliert werden.

Die breite Palette der von OSAI entwickelten Multisocket- und Multipick-Up-Tools ermöglicht es den Kunden, verschiedene Pakete zu verwalten.

NeoHandler kann mit verschiedenen Stimuluskammern richtig konfiguriert werden, entsprechend den spezifischen zu konditionierenden MEMS.

VIDEO ABSPIELEN

DATENBLATT HERUNTERLADEN

Handler Schwerpunkte:

Kompatible Bauelemente

die Handler wird als eine allgemeine Ausrüstung realisiert

Allerdings wird die vollständige Kompatibilität für gewisse Bauelemente von den Kontakten gegeben.

Die Handler ist kompatibel mit folgenden Bauelementen:

HANDLING

RÜCKSEITIGE TABLETTS INPUT-OUTPUT-WAGEN:

OSAI NeoHandler ist mit einem Input-Output-Wagen ausgestattet.

Die Wagenoptionen sind so konzipiert, dass sie immer dann geändert werden, wenn eine Neukonfiguration des Handlers erforderlich ist, was die Aufbauzeit reduziert.

Ein schnell wechselndes System mit einem mechanischen Selbstausrichtsystem garantiert die Wiederholgenauigkeit des Input-Outputs.

Der Wagen kann mit verschiedenen Arten von Zuführlösungen für den Input/Output konfiguriert werden.

Input:

- Jedec Tablettzuführung

- Rohr

- Schüssel

- Filmrahmen

Output:

- Jedec Tablett

- Rohr

- T&R

- Schüssel

TOOLS

JEDER KOPF IST MIT EINEM SPEZIELLEN PICK-UP- WERKZEUG AUSGESTATTET

Hauptmerkmale der Pick-Up-Werkzeuge sind:

- Schnelles Wechseln (weniger als 1 Minute)

- 1, 4, 8, 16, 35 Standorte andere Multisites sind auf der Roadmap verfügbar

- Unabhängiger 10mm Z-Hub auf jedem einzelnen Pflücker

- Unabhängige Vakuumsteuerung und -kontrolle an jedem einzelnen Sammler

- Fein einstellbarer Abluftbläser

- Einseitiger Kollisionssensor

- Auf dem Sammler-Präzisor für die Gerätevorausrichtung

- Interner Code für die Überprüfung der Einrichtungsrezeptur

NEOT-LAB

Labormaßstabausrüstung für MEMS Umgebungssensoren

Neo T-LAB ist die ultimative kompakte Lösung von OSAI. Mit seiner kompakten Größe ist Neo T-LAB eine der kleinsten Konditionierungskammern der Welt und dessen kompaktes Design ermöglicht die Feinabstimmung von Forschung und Entwicklung direkt im Labor.

Neben der kleinen Standfläche bietet Neo T-LAB die Möglichkeit, mit unterschiedlichen Stimuli wie Temperatur, Druck, Feuchtigkeit und Gas ausgestattet zu werden.

Neo T-LAB ist auch eine maßgeschneiderte Lösung: Die Möglichkeit, die Kammer nach Kundenwunsch zu gestalten, ermöglicht es dieser Lösung, in wenigen Schritten vom Labor zur Serienproduktion überzugehen.

VIDEO ABSPIELEN

DATENBLATT HERUNTERLADEN

EPC’s Keypoints

STIMULI

ENGINEERING PRESSURE CHAMBER

HAUPTEIGENSCHAFTEN:

- Temperaturbereich: -20° up to 80°C or -40° up to 125°C

- Temperaturgenauigkeit: 0,5°C

- Temperaturbeständigkeit: 0,3°C

- Durchschnittliche Einschwingzeit: 10s

- Druckbereich: 0 up to 6bar

- Druck Einschwingzeit: 3s

- Druckbeständigkeit: nach externem Regler

- MEMS-Kommunikation Protokoll: SPI, I2C, GPIO

- PC Interface: USB

STIMULI

HIGH ACCURATE STIMULI

- Thermal stimuli unit

- Pressure stimuli unit

- Gas stimuli unit

- Humidity stimuli unit

NEOHANDLER

Mass Production

Test Handler for MEMS

OSAI neohandler is the top-notch solution for Semiconductor Companies, for testing MEMS and Power devices in mass production (up to 25KUPH). Neohandler small footprint 900 x 1.600mm saves production area, increasing drastically the throughput (UPH / m2), by using scalable concept.

High flexibility allows the customer to change setup in 15 minutes, maximizing the investment: Input / output trolley can be replaced with different magazine type and Multipick up tool can be easily and simply scaled according to the need.

The wide range of Multisocket and multipick up tools developed by OSAI, allows the customers to manage different packages. Neohandler can be properly configured with different Stimulus Chambers, according to specific MEMS to be conditioned.

PLAY VIDEO

DOWNLOAD DATA SHEET

Handler’s Keypoints

Acceptable devices packages

The Handler is conceived as a general purpose equipment.

However the full compatibility for a certain package is given from the contactors.

The Handler is compatible with the following packages:

HANDLING

REAR SIDE TRAYS INPUT OUTPUT TROLLEY:

The Handler is equipped with an input/output trolley.

Trolley is conceived to be changed on field to reduce the setup time in case of a Handler re-configuration.

A fast changing system with a mechanical self alignment system guarantees the input output repeatability.

Trolley can be configured with different kinds of input output feeding.

Input:

- Jedec Tray Feeder

- Tube

- Bowl

- Film frame

Output:

- Jedec Tray

- Tube

- T&R

- Bowl

TOOLS

EACH HEAD IS EQUIPPED WITH A SPECIFIC PICK-UP TOOL

Main characteristics of the Pick-Up tools are:

- Fast changing (less than 1 minute) and standard Osai interface (includes all the electrical and pneumatic connections)

- 1, 4, 8, 16, 35 sites, other multisite available on the roadmap

- Independent 10mm Z stroke each single picker

- Independent vacuum command and control on each single picker

- Fine adjustable detaching air blow

- Single site collision sensor

- On picker precisor for device pre-alignment

- Internal code for setup-recipe verification

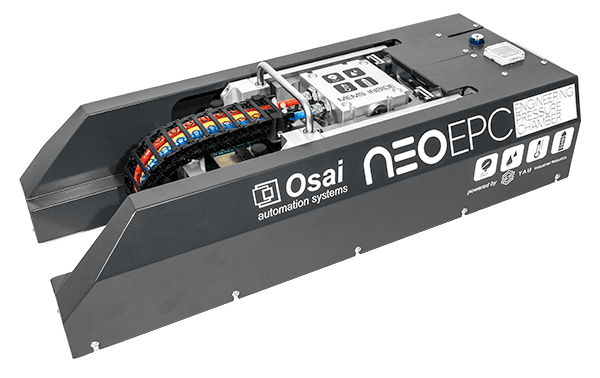

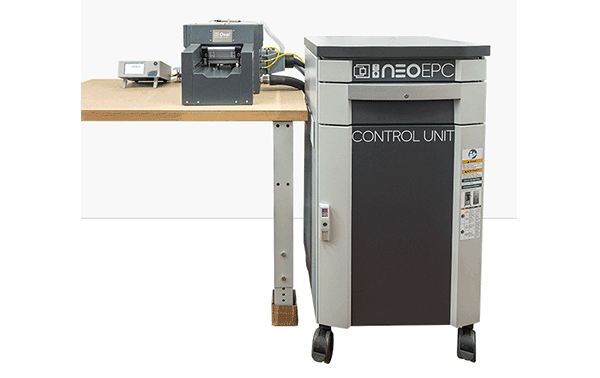

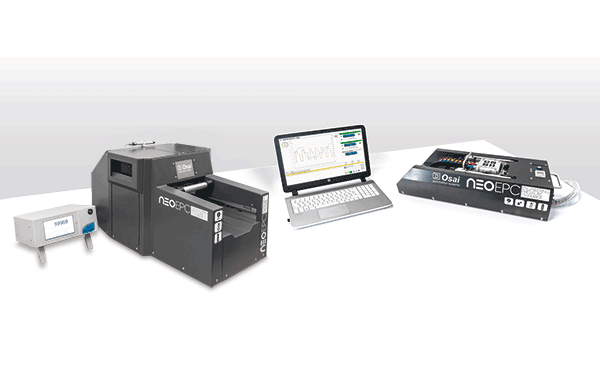

NEOEPC

Lab Scale Equipment

Neo Epc is the ultimate Osai’s testing solution. With its small size NeoEpc is one of the smallest conditioning chamber in the world and its compact design allow the R&D fine tuning directly on laboratory.

This characteristic allows to equip the chamber with different stimuli, such as temperature, pressure, humidity and gas and process different geometries (from 1×1 to 3×3 mm).

NeoEpc is also a tailor made solution: the chance to design the chamber basing on customer needs allows this solution to go from laboratory to mass production in just a few steps.

PLAY VIDEO

DOWNLOAD DATA SHEET

EPC’s Keypoints

STIMULI

ENGINEERING PRESSURE CHAMBER

MAIN CHARACTERISTICS

- Temperature range: -20° up to 80°C or -40° up to 125°C

- Temperature accurancy: 0,5°C

- Temperature stability: 0,3°C

- Average setting time: 10s

- Pressure range: 0 up to 6bar

- Pressure setting time: 3s

- Pressure stability: according to external regulator

- MEMS communication protocol: SPI, I2C, GPIO

- PC Interface: USB

STIMULI

HIGH ACCURATE STIMULI

- Thermal stimuli unit

- Pressure stimuli unit

- Gas stimuli unit

- Humidity stimuli unit