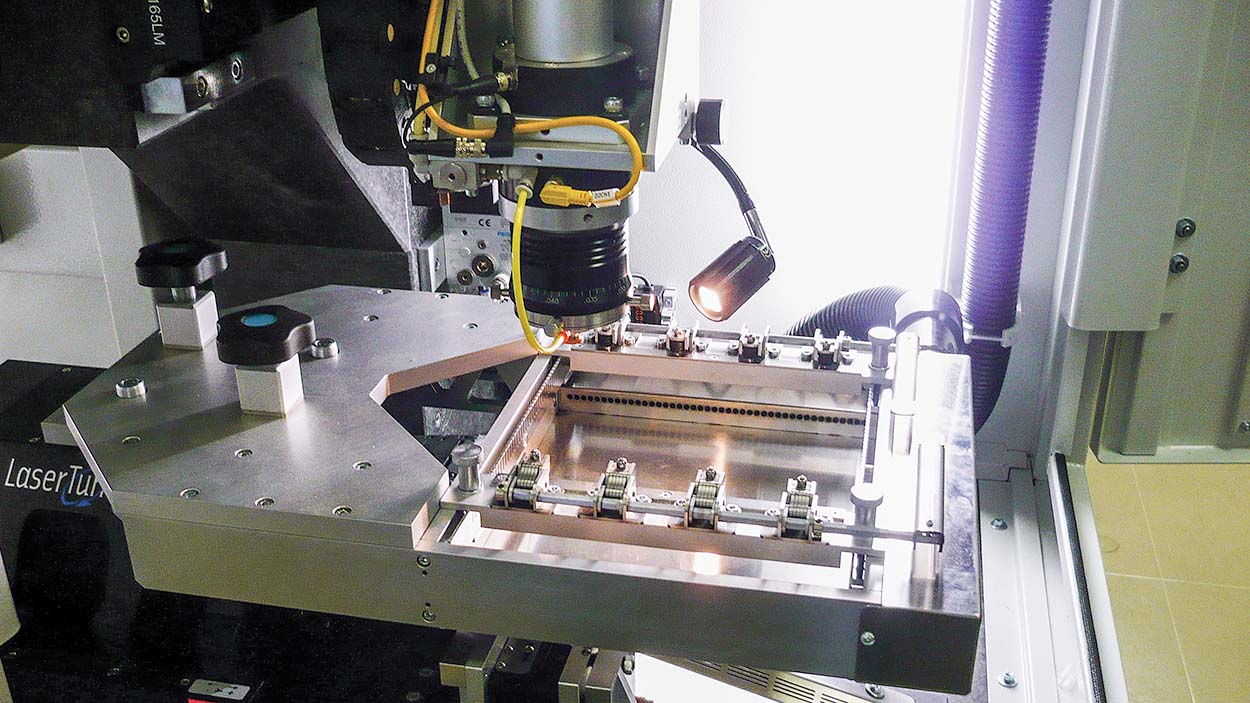

Granite base high precision Laser cutting machine

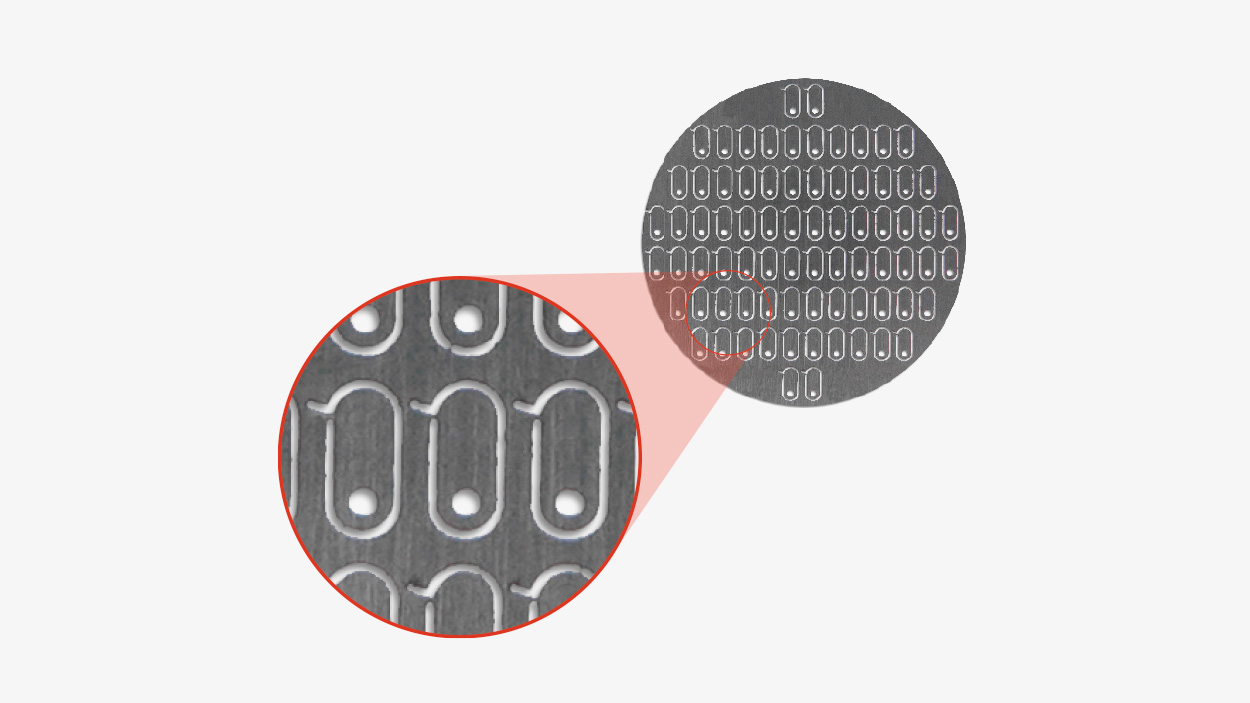

FineCut 200 is a Class 1 Laser micro-cutting system for tubes. Built on a highly stable granite structure. Tailor-made for medical device manufacturing, particularly for coronary and vascular stents in CoCr or Ni-Ti alloys, heart valves, hypo-tubes, insulin pens, and metal needles, it can also be used in the production of jewelry such as bracelets and rings.

Optionally equipped with a small XY table, it can also perform 2D cuts on sheet metal. The motion is achieved via a precise and extremely repeatable set of CNC-controlled axes and the integration of the latest generation of fiber or ultra-short pulse Laser sources guarantee production with exceptional finishes.

The user interface is enhanced through an HMI featuring integrated CAD/CAM functionality, allowing for the direct import of graphic files.

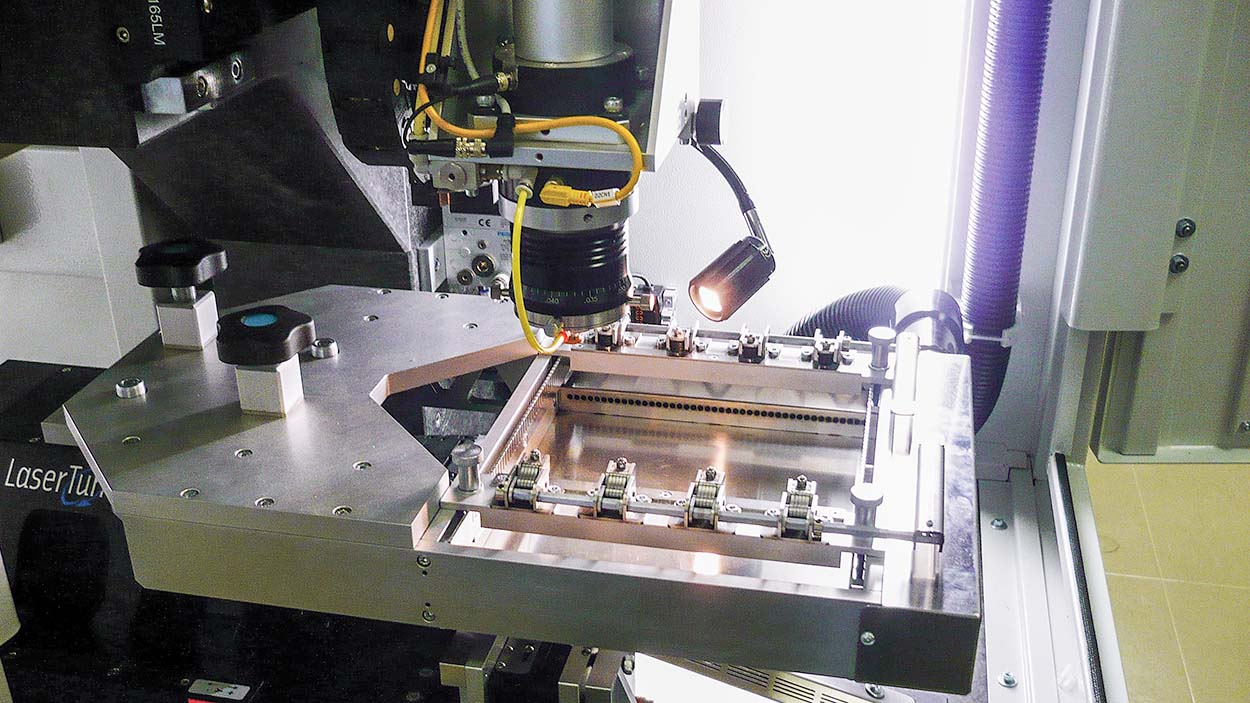

Granite base high precision Laser cutting machine

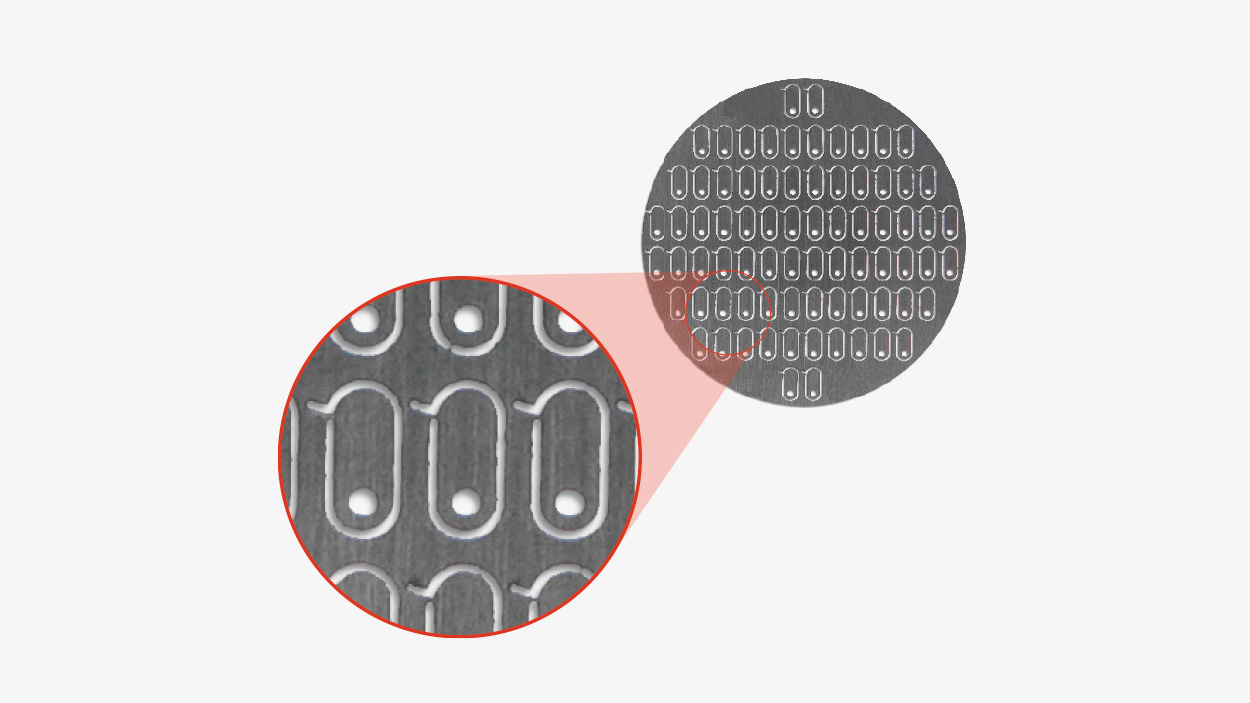

FineCut 200 is a Class 1 Laser micro-cutting system for tubes. Built on a highly stable granite structure. Tailor-made for medical device manufacturing, particularly for coronary and vascular stents in CoCr or Ni-Ti alloys, heart valves, hypo-tubes, insulin pens, and metal needles, it can also be used in the production of jewelry such as bracelets and rings.

Optionally equipped with a small XY table, it can also perform 2D cuts on sheet metal. The motion is achieved via a precise and extremely repeatable set of CNC-controlled axes and the integration of the latest generation of fiber or ultra-short pulse Laser sources guarantee production with exceptional finishes.

The user interface is enhanced through an HMI featuring integrated CAD/CAM functionality, allowing for the direct import of graphic files.